Method for preparing SAPO-34 molecular sieve, SAPO-34 molecular sieve and application of SAPO-34 molecular sieve

A SAPO-34 and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of metal loss, poor hydrothermal stability, and uneven distribution of metal oxides, and achieve high ethylene and propylene selectivity, slow deactivation rate, and high crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

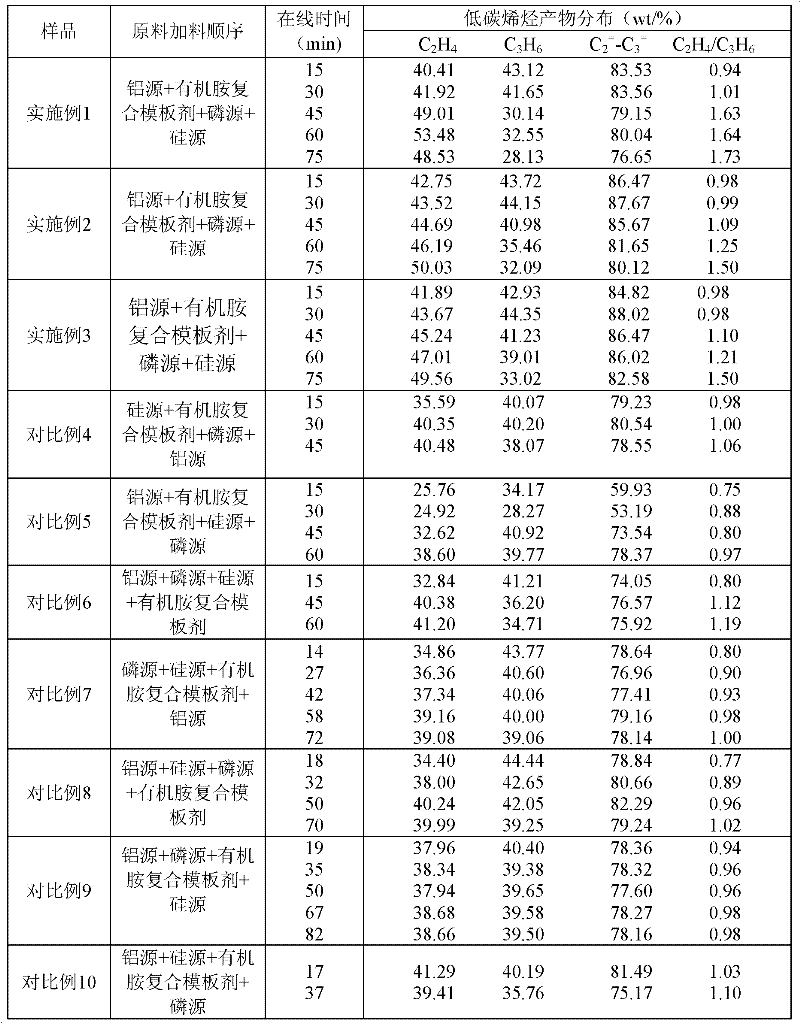

Embodiment 1

[0065] The silicon source and phosphorus source are mixed first, and then the basic composite template formed by aluminum source, organic amine and fluoride is added in sequence.

[0066] Weigh 6.12g silica sol, dissolve in 20.06g deionized water and stir evenly to prepare silica sol dilute solution; 13.842g of 85% H 3 PO 4 Dissolve it in 16.57g of water, stir evenly, and then add it into the dilute silica sol solution to obtain a mixed solution of silicon and phosphorus. Weigh 9.90g of pseudo-boehmite, add 20.14g of deionized water, stir well for 1h, and add into the mixed solution of silicon and phosphorus. After mixing 18.18g of TEA (triethylamine) and 0.08g of NaF, they were added to the mixture containing Si source, P source, and Al source, and fully stirred. The molar composition of the resulting mixture is:

[0067] 3.0Et 3 N:0.6SiO2 2 :Al 2 o 3 :P 2 o 5 : 60H 2 O: 0.05NaF

[0068] Keep the above-mentioned composite template gel containing silicon, phosphorus...

Embodiment 2

[0073] The silicon source and phosphorus source are mixed first, and then the basic composite template formed by aluminum source, organic amine and fluoride is added in sequence.

[0074] Weigh 6.12g of silica sol, dissolve in 20.06g of water and stir evenly to prepare silica sol dilute solution; 13.842g of 85%H 3 PO 4 Dissolve it in 16.57g of water, stir evenly, and then add it into the dilute silica sol solution to obtain a mixed solution of silicon and phosphorus. Weigh 9.90g of pseudo-boehmite, add 20.14g of water, stir thoroughly for 1h, and add into the mixed solution of silicon and phosphorus. After mixing 18.18g of TEA (triethylamine) and 0.08g of NaF, they were added to the mixture containing Si source, P source, and Al source, and fully stirred. The molar composition of the resulting mixture is:

[0075] 3.0Et 3 N:0.6SiO2 2 :Al 2 o 3 :P 2 o 5 : 60H 2 O: 0.05NaF

[0076] Keep the gel of the composite template agent containing silicon, phosphorus, aluminum, ...

Embodiment 3

[0081] The silicon source and phosphorus source are mixed first, and then the basic composite template formed by aluminum source, organic amine and fluoride is added in sequence.

[0082] Weigh 6.12g of silica sol, dissolve in 20.06g of water and stir evenly to prepare silica sol dilute solution; 13.842g of 85%H 3 PO 4 Dissolve it in 16.57g of water, stir evenly, and then add it into the dilute silica sol solution to obtain a mixed solution of silicon and phosphorus. Weigh 9.90g of pseudo-boehmite, add 20.14g of water, stir thoroughly for 1h, and add into the mixed solution of silicon and phosphorus. After mixing 18.18g of TEA (triethylamine) and 0.08g of NaF, they were added to the mixture containing Si source, P source, and Al source, and fully stirred. The molar composition of the resulting mixture is:

[0083] 3.0Et 3 N:0.6SiO2 2 :Al 2 o 3 :P 2 o 5 : 60H 2 O: 0.05NaF

[0084] Keep the above-mentioned gel containing silicon, phosphorus, aluminum, and fluoride-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com