Preparation method of spherical tin-doped indium oxide nanopowder

A tin-doped indium oxide and nano-powder technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve problems such as difficult process control, pollution, operator and environmental hazards, and achieve simplified production process, The effect of reducing production costs and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

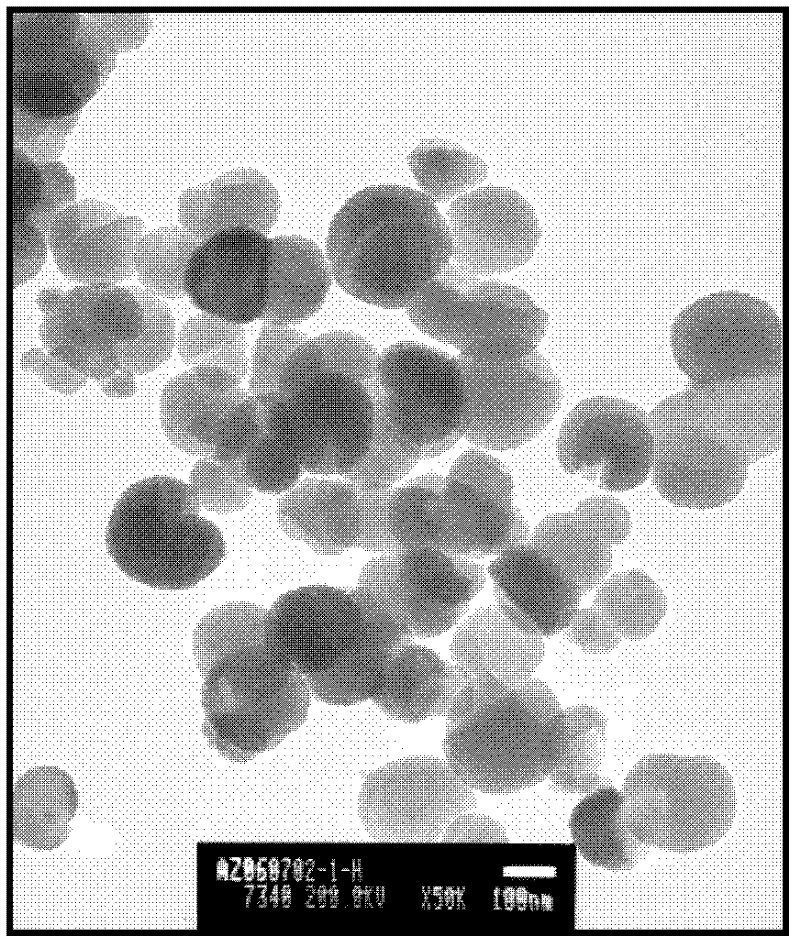

[0032] Weigh 3.5 moles of indium chloride and dissolve it in 7 liters of deionized water to prepare a solution with a molar concentration of 0.5 mol / L. Then add 0.35 moles of tin chloride, so that the molar ratio of tin ions to indium metal ions is 0.1. After fully stirring and dissolving at room temperature, add 25% ammonia water dropwise to the solution pH=11 with an automatic titrator, and transfer the solution to In a 10L polytetrafluoroethylene or alkali corrosion-resistant metal-lined stainless steel reactor coated with anti-corrosion materials, the filling degree of the reactor is 70%, and the hydrothermal treatment is carried out at 260 degrees Celsius for 6 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for 6-12 hours to obtain a single dispersed tin-doped indium oxide powder. It can be determined by TEM analysis that the particles in the tin-doped indium oxide powder have...

Embodiment 2

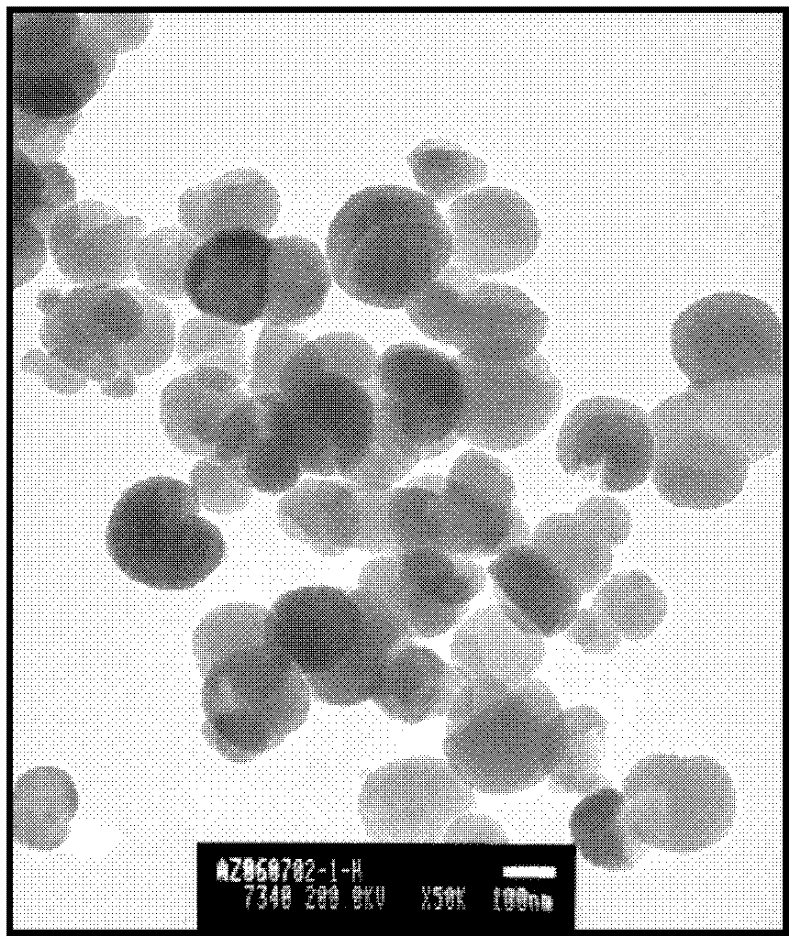

[0034] Weigh 3.5 moles of indium chloride and dissolve it in 7 liters of deionized water to prepare a solution with a molar concentration of 0.5 mol / L. Then add 0.35 moles of tin chloride, so that the molar ratio of tin ions to indium metal ions is 0.1. After fully stirring and dissolving at room temperature, add 25% ammonia water dropwise to the solution pH=11 with an automatic titrator, and transfer the solution to In a 10L polytetrafluoroethylene or alkali corrosion-resistant metal-lined stainless steel reactor coated with anti-corrosion materials, the filling degree of the reactor is 70%, and the hydrothermal treatment is carried out at 300 degrees Celsius for 6 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for 6-12 hours to obtain a single dispersed tin-doped indium oxide powder. It can be determined by TEM analysis that the particles in the tin-doped indium oxide powder are ...

Embodiment 3

[0036]Weigh 3.5 moles of indium chloride and dissolve it in 7 liters of deionized water to prepare a solution with a molar concentration of 0.5 mol / L. Then add 0.35 moles of tin chloride, so that the molar ratio of tin ions to indium metal ions is 0.1. After fully stirring and dissolving at room temperature, add 25% ammonia water dropwise to the solution pH=11 with an automatic titrator, and transfer the solution to In a 10L polytetrafluoroethylene or alkali corrosion-resistant metal-lined stainless steel reactor coated with anti-corrosion materials, the filling degree of the reactor is 70%, and the hydrothermal treatment is carried out at 360 degrees Celsius for 6 hours. The product is washed about 5 times with deionized water to remove acid radical ions and impurity ions, and dried at 100 degrees Celsius for 6-12 hours to obtain a single dispersed tin-doped indium oxide powder. It is determined by TEM analysis that the particles in the tin-doped indium oxide powder have a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com