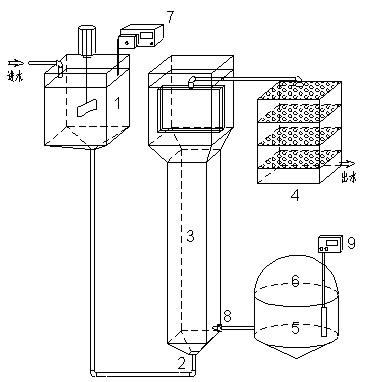

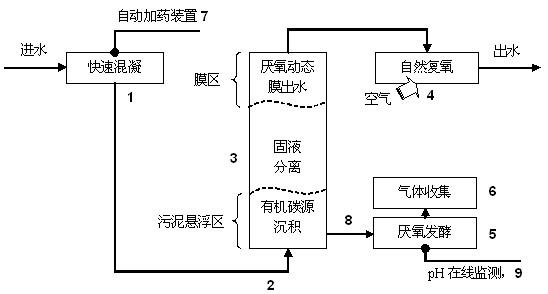

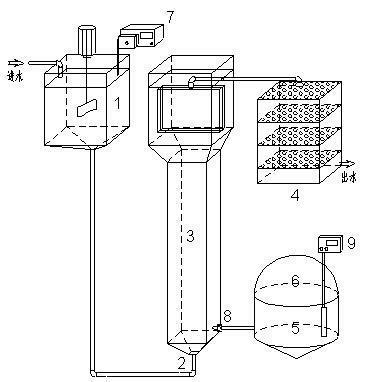

Process and device of low energy consumption sewage treatment based on carbon source recovery

A sewage treatment, low energy consumption technology, applied in the field of environmental protection and sewage treatment, can solve the problems of difficult solid-liquid separation, low solid content of sludge, oxygen consumption, etc., to improve the solid-liquid separation effect, improve the settling performance, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A low-energy sewage treatment process based on carbon source recovery, using polyferric chloride PFC as a polymer coagulant (dosage 50 g PFC / ton of water), after the raw sewage water is efficiently coagulated in a rapid sedimentation tank, the hydraulic retention time is 2 minutes , enter the anaerobic dynamic membrane-bioreactor for anaerobic treatment and solid-liquid separation, and the hydraulic retention time is 2.5h. The dynamic membrane module flux in the anaerobic reactor is 100 L / (m 2 h), the organic load of the reactor is 2.20 kg COD / (m 3 d). This process treats domestic sewage in a southern city. The influent COD concentration is 300.4±68.8 mg / L, the ammonia nitrogen concentration is 31.0±6.5 mg / L, the total nitrogen concentration is 51.3±13.4 mg / L, and the total phosphorus concentration is 7.2±3.4 mg / L. L; the effluent COD concentration of the device is 82.7±16.6 mg / L, the ammonia nitrogen concentration is 21.2±3.4 mg / L, and the total phosphorus concentrat...

Embodiment 2

[0030] A low-energy sewage treatment process based on carbon source recovery, using polysilicate ferric chloride PFSC as a polymer coagulant (dosage 75 g PFSC / ton of water), after the raw sewage water is efficiently coagulated in a rapid sedimentation tank, hydraulic retention After 2 minutes, it enters the anaerobic dynamic membrane-bioreactor for anaerobic treatment and solid-liquid separation, and the hydraulic retention time is 2.2h. The flux of the dynamic membrane module in the anaerobic reactor is 60 L / (m 2 h), the organic load of the reactor is 3.27 kg COD / (m 3 d). Using this sewage treatment process to treat a city's domestic sewage, the influent COD concentration is 234.6-680.8 mg / L, the ammonia nitrogen concentration is 23.2-43.5 mg / L, the total nitrogen concentration is 45.3-68.7 mg / L, and the total phosphorus concentration is 3.8-10.6 mg / L ;The concentration of COD in the effluent of the device is 24.6~88.7mg / L, the concentration of ammonia nitrogen is 14.3...

Embodiment 3

[0032] A low-energy sewage treatment process based on carbon source recovery, using polysilicate ferric chloride PFSC as a polymer coagulant (dose 50 g PFSC / ton of water), after the raw sewage water is efficiently coagulated in the rapid sedimentation tank, the hydraulic retention After 2 minutes, it enters the anaerobic dynamic membrane-bioreactor for anaerobic treatment and solid-liquid separation, and the hydraulic retention time is 1.2h. The flux of the dynamic membrane module in the anaerobic reactor is 65 L / (m 2 · h), the organic load of the reactor is 3.10 kg COD / (m 3 d). This sewage treatment process was used to treat domestic sewage in a rural area. The influent COD concentration was 128.3~289.8 mg / L, the ammonia nitrogen concentration was 12.6~39.2 mg / L, the total nitrogen concentration was 23.8~55.7 mg / L, and the total phosphorus concentration was 1.6~5.5 mg / L. L; the concentration of COD in the effluent of the device is 36.3~83.8mg / L, the concentration of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com