Steel slag grinding aid and preparation method thereof

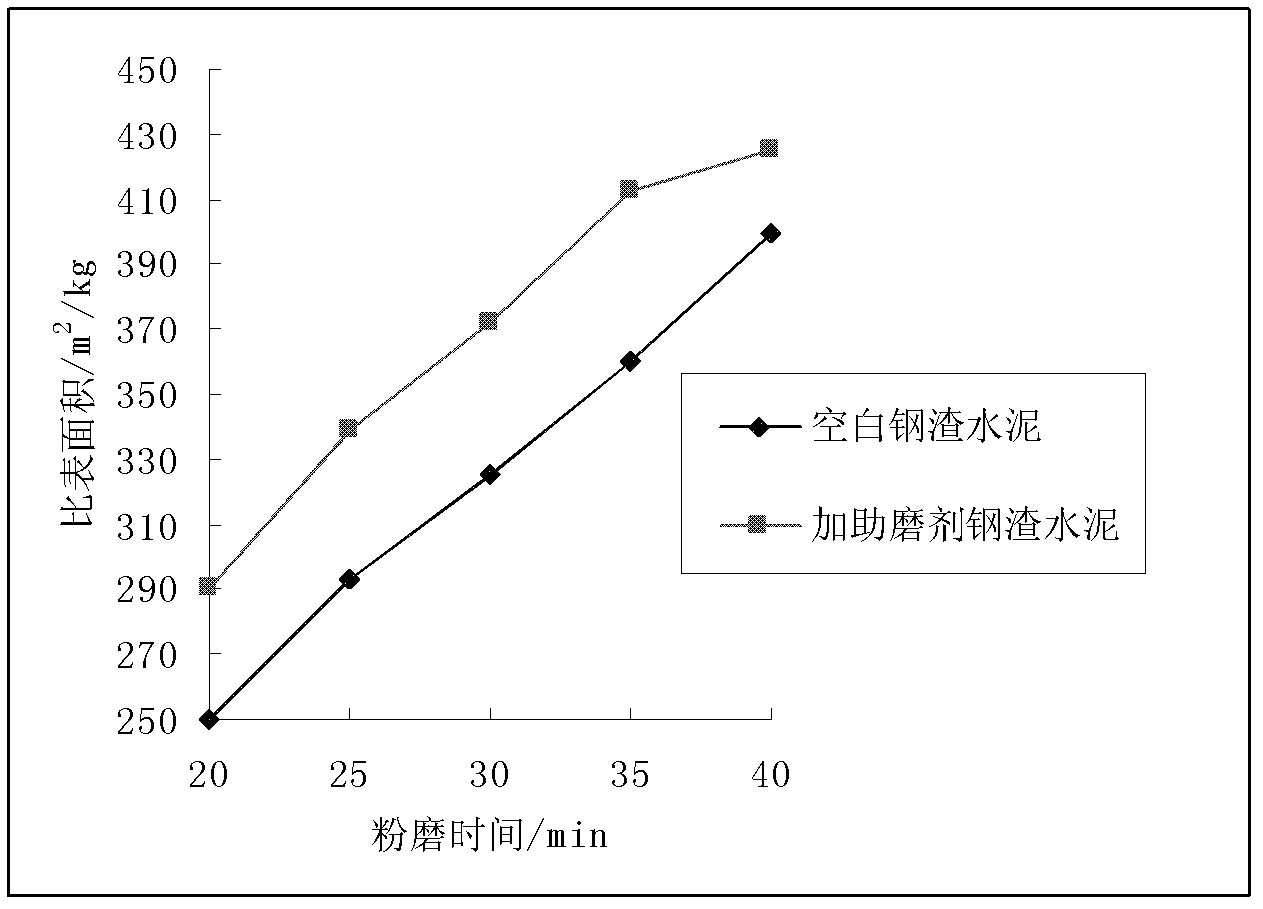

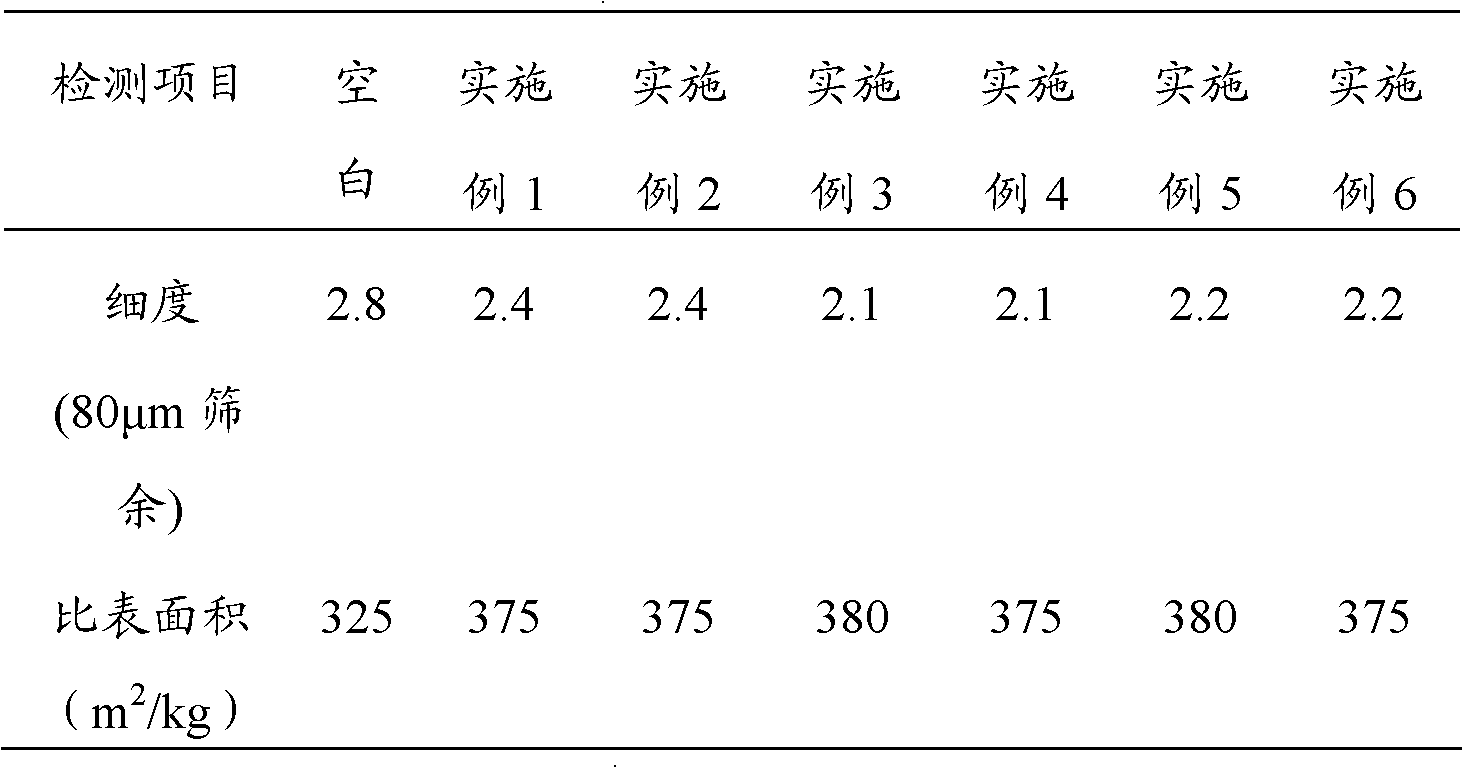

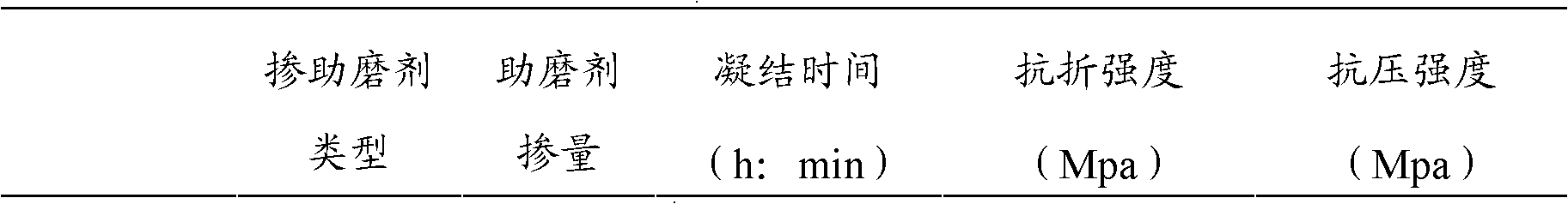

A grinding aid and steel slag technology, which is applied in the field of grinding aids, can solve the problems of high cost and ineffective improvement, and achieve the effects of increased compressive strength, various spatial configurations, and increased activity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention discloses a preparation method of a steel slag grinding aid, which comprises the following steps:

[0026] Mix 40-70 parts by weight of organic amines containing N-H bonds, 50-70 parts by weight of aldehydes and 3-6 parts by weight of ammonia water, heat up to 90-100°C, and react to obtain alcohol amines, The organic amines containing N-H bonds are acrylamide or melamine; the alcohol amines, 50-80 parts by weight of water, 10-25 parts by weight of inorganic salts, 3-5 parts by weight of mixed alcohol and 10 ~ 15 parts by weight of sulphite pulping waste liquid are mixed and stirred to obtain a steel slag grinding aid.

[0027] In the preparation process of the above-mentioned steel slag grinding aid, the present invention first utilizes the N-H bond in acrylamide or melamine to react with aldehyde compounds to form alcohol amines. The aldehyde compound is preferably formaldehyde or acetaldehyde, so that the N—H bond reacts with formaldehyde or acetaldehyd...

Embodiment 1

[0044] Inject 70 parts by weight of acrylamide into the reactor at one time, heat it to 85°C, then uniformly add 60 parts by weight of formaldehyde solution and 3 parts by weight of ammonia water into the reactor at the same time, the feeding time is 1.5 hours, and keep warm at 100°C for 3 hour, obtain alcohol amines;

[0045] Cool the above-prepared alcohol amines to room temperature, then add 60 parts by weight of water into the reactor, and stir thoroughly to obtain an aqueous solution, then add 15 parts by weight of sodium phosphate, 5 parts by weight of mixed alcohol, waste 10 parts by weight of the solution are sequentially added into the reaction vessel, and stirred while adding, and the obtained product is the steel slag grinding aid.

Embodiment 2

[0047] Inject 50 parts by weight of acrylamide into the reactor at one time, heat it to 85°C, then add 70 parts by weight of acetaldehyde solution and 3 parts by weight of ammonia water into the reactor at the same time, the feeding time is 2 hours, and keep warm at 100°C for 3 hour, obtain alcohol amines;

[0048] Cool the above-prepared alcohol amines to room temperature, then add 50 parts by weight of water into the reactor, and stir thoroughly to obtain an aqueous solution, then add 10 parts by weight of sodium phosphate, 5 parts by weight of mixed alcohol, waste 10 parts by weight of the solution are sequentially added into the reaction vessel, and stirred while adding, and the obtained product is the steel slag grinding aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com