Preparation method of fibroins of different forms

A technology of silk fibroin and morphology, which is applied in the field of preparation of silk fibroin of different shapes, to achieve the effect of unique physical and chemical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

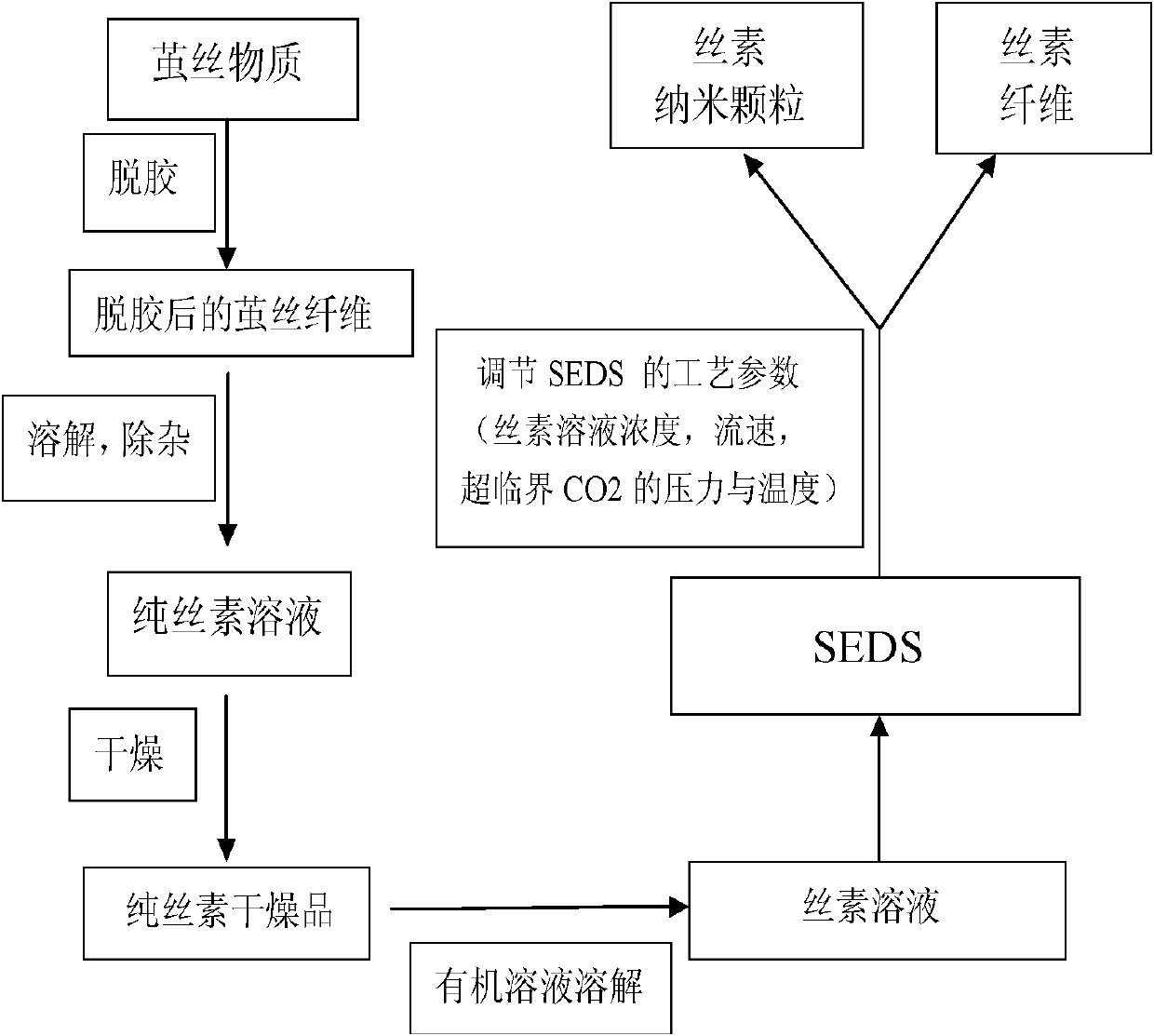

[0050] figure 1 It is a flowchart of the preparation method of different forms of silk fibroin of the present invention. From figure 1 As can be seen, the preparation method of the present invention mainly comprises the following steps:

[0051] 1. Degumming of silk: use high temperature and high pressure water or boiled Na 2 CO 3 solution treatment to remove the sericin part of the cocoon silk material, then rinse with deionized water and then dry to obtain the degummed dry cocoon silk material. The cocoon silk material referred to here may include one or more of cocoon silk, spun silk and raw silk. In addition, high-temperature and high-pressure water refers to water having a temperature of 100 to 130° C. and a pressure of 0 to 0.18 MPa. It should be noted that all numerical ranges in which the lower limit is 0 herein do not include the lower limit of 0, but include the corresponding upper limit.

[0052] 2. Preparation of dried silk fibroin: dissolve the degummed dry ...

Embodiment 1

[0060] Put 100g of cocoon silk into deionized water, and then react in a steam heater at 120°C and 0.1MPa for 60min to remove the sericin on the surface. The degumming rate was measured by biuret reaction and weighing method, and the results confirmed that the silk surface sericin had been completely removed. Subsequently, the obtained degummed cocoon silk was rinsed with deionized water and dried for the next step.

[0061] Put 15g of dried degummed cocoon silk into 1000ml CaCl at 70°C 2 :CH 3 CH 2 OH:H 2 O=1:2:8 (mol) ternary solvent reacted for 6h to obtain silk fibroin solution. Then use a semi-permeable membrane to remove salt and other impurities to obtain a pure silk fibroin aqueous solution, and then use a freeze dryer to dry the solution to obtain a pure silk fibroin dry product.

[0062] The prepared dried silk fibroin was dissolved in hexafluoroisopropanol to obtain a 0.5% (mass volume ratio) silk fibroin organic solution.

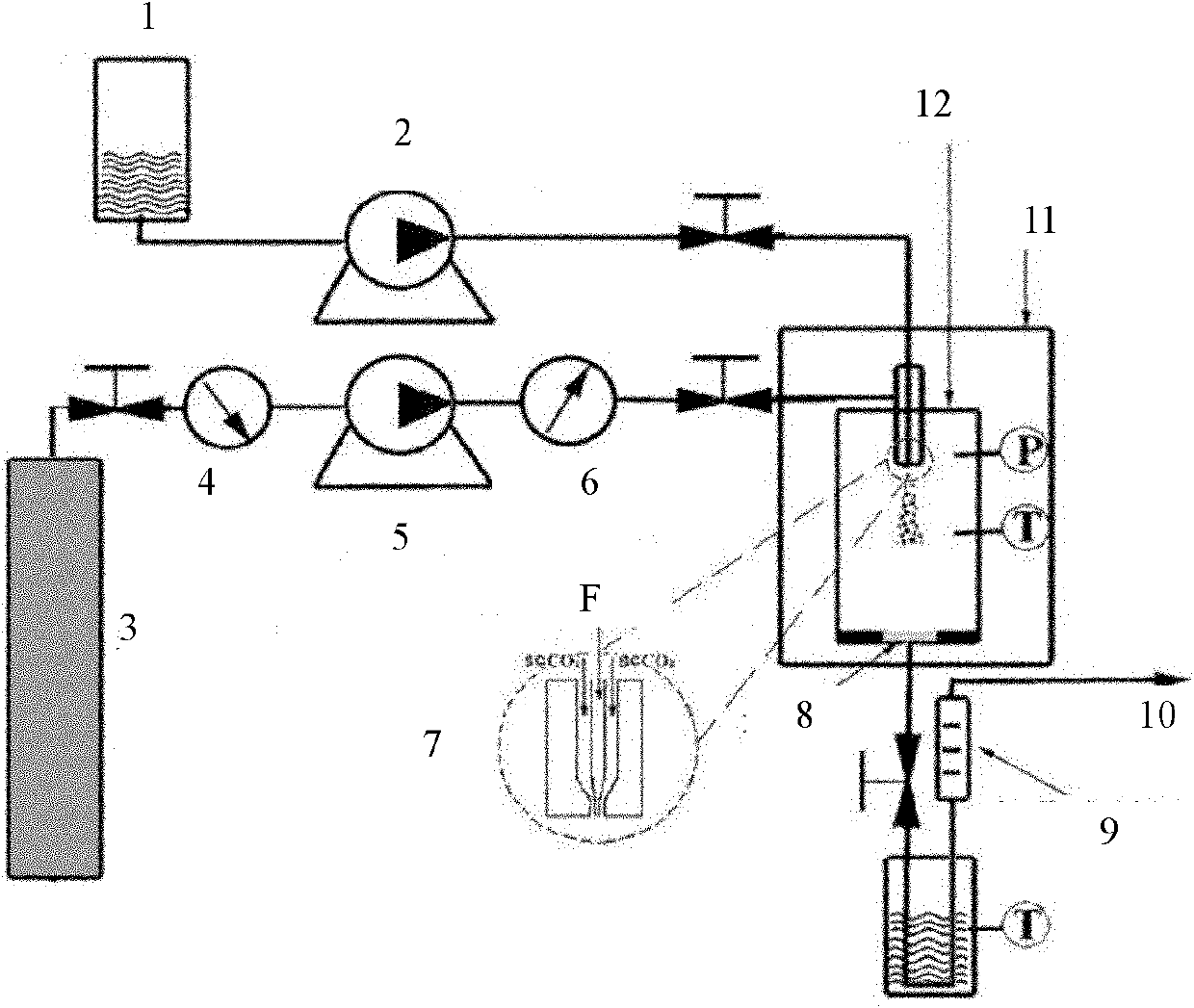

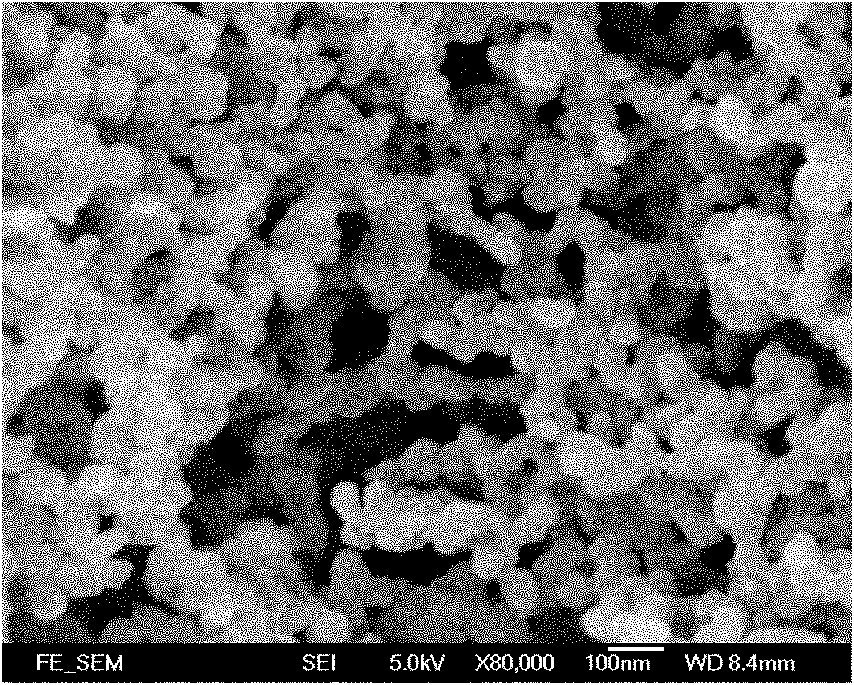

[0063] Finally, the silk fibroin na...

Embodiment 2

[0078] Put 100g raw silk into boiled 0.5% sodium carbonate solution, react for half an hour to remove the sericin on the surface. The degumming rate was measured by biuret reaction and weighing method, and the results confirmed that the silk surface sericin had been completely removed. Subsequently, the resulting degummed raw silk was rinsed with deionized water and dried for the next step.

[0079] Put 25g of dried degummed raw silk into 1000ml of CaCl at 70°C 2 :CH 3 CH 2 OH:H 2 O=1:2:8 (mol) ternary solvent reacted for 8h to obtain silk fibroin solution. Then use a semi-permeable membrane to remove salt and other impurities to obtain a pure silk fibroin aqueous solution, and then use a freeze dryer to dry the solution to obtain a pure silk fibroin dry product.

[0080] The prepared dried silk fibroin was dissolved in hexafluoroisopropanol to obtain a 4% (mass volume ratio) silk fibroin organic solution.

[0081] Finally, the silk fibroin fiber was prepared by utilizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com