Vinyl acetate copolymer modified by silsesquioxane (tris sulfonic acid isobutyl polyhedral oligomeric silsesquioxane (POSS)) and preparation method thereof

A technology of silsesquioxane and vinyl acetate, applied in the field of silsesquioxane-modified vinyl acetate copolymer and its preparation, to achieve the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

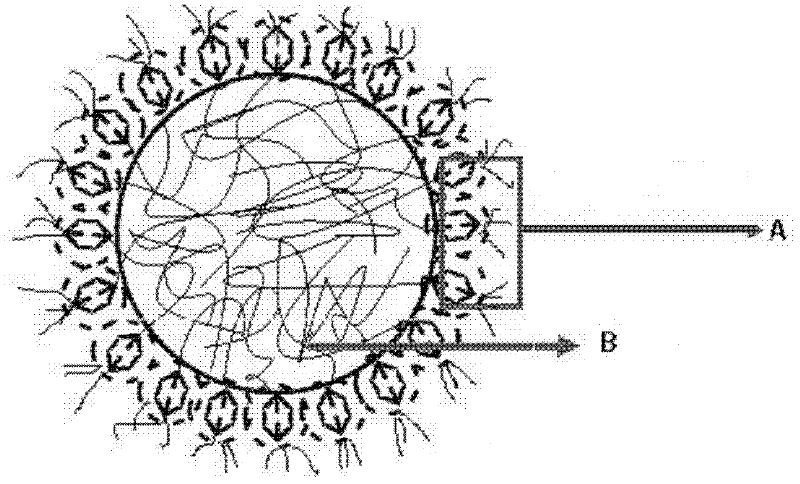

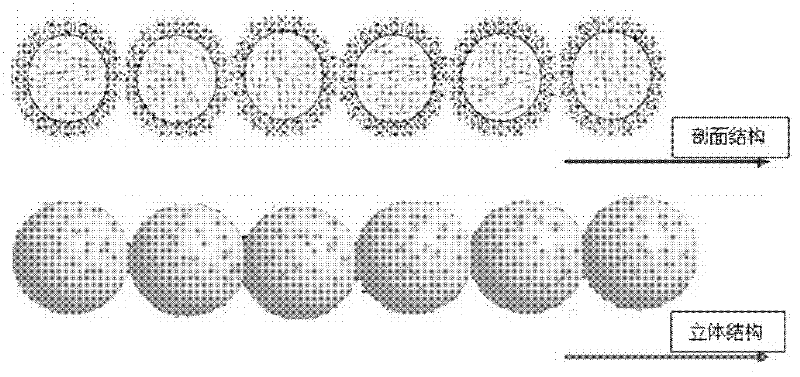

Image

Examples

Embodiment 1

[0022] A reaction device containing a stirrer, a reflux condenser and a dropping funnel (2) was built on a 500ml four-necked flask, a magnetic rotor was placed in the four-necked flask, and 50ml of ionized water and 6g of polyvinyl alcohol were added. The device is placed in a digital display intelligent temperature-controlled magnetic stirrer to heat in a water bath, turn on condensation reflux, stir, adjust the speed, and adjust the water temperature to 50°C until the polyvinyl alcohol is completely dissolved. 2 g of methyl methacrylate, 3 g of ethyl methacrylate, 3 g of butyl methacrylate, 3 g of acrylic acid, and 4 g of hydroxyethyl methacrylate were mixed and added to the dropping funnel. Adjust the water temperature to 65°C, add 3ml of 4% OP-10 solution, 3g of Tris Sulfonic Acid Isobutyl POSS (product of Hybrid Plastics), and 1g of ammonium persulfate (dissolved in 10ml of deionized water) into the four-necked flask, and start dropping at the same time. 45g of vinyl acet...

Embodiment 2

[0026]A reaction device containing a stirrer, a reflux condenser and a dropping funnel (2) was built on a 500ml four-necked flask, a magnetic rotor was placed in the four-necked flask, and then 30ml of ionized water and 4g of polyvinyl alcohol were added. The device is placed in a digital display intelligent temperature-controlled magnetic stirrer to heat in a water bath, turn on condensing reflux, stir, adjust the rotation speed appropriately, and adjust the water temperature to 50 °C until the polyvinyl alcohol is completely dissolved. 1 g of methyl methacrylate, 2 g of ethyl methacrylate, 2 g of butyl methacrylate, 2 g of acrylic acid, and 3 g of hydroxyethyl methacrylate were mixed and added to the night dropping funnel. Adjust the water temperature to 70°C, add 2ml of 4% OP-10 solution, 2g of Tris Sulfonic Acid Isobutyl POSS, 0.4g of ammonium persulfate (dissolved in 10ml of deionized water) into the four-necked flask, and dropwise add 35g of vinyl acetate and 10g of The ...

Embodiment 3

[0030] A reaction device containing a stirrer, a reflux condenser and a dropping funnel (2) was built on a 500ml four-necked flask, a magnetic rotor was placed in the four-necked flask, and 40ml of ionized water and 4.5g of polyvinyl alcohol were added. Put the device into a digital display intelligent temperature-controlled magnetic stirrer for heating in a water bath, turn on condensation reflux, stir, adjust the speed appropriately, and adjust the water temperature to 50 °C until the polyvinyl alcohol is completely dissolved. 1.5 g of methyl methacrylate, 2.5 g of ethyl methacrylate, 2.5 g of butyl methacrylate, 2.5 g of acrylic acid, and 3.5 g of hydroxyethyl methacrylate were mixed and added to the night dropping funnel. Adjust the water temperature to 70°C, add 2.5ml of 4% OP-10 solution, 2.5g of Tris Sulfonic Acid Isobutyl POSS, 0.6g of ammonium persulfate (dissolved in 10ml of deionized water) into the four-necked flask, and dropwise add 40g of vinyl acetate and 13.5 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wet strength | aaaaa | aaaaa |

| Coating hardness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com