Method for preparing water-soluble polyester based on aluminum compound as catalyst

A technology of water-soluble polyester and aluminum compound, applied in the field of preparation of water-soluble polyester, can solve the problems of difficult popularization and application, yellowish appearance of the product, insufficient activity of aluminum compound, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

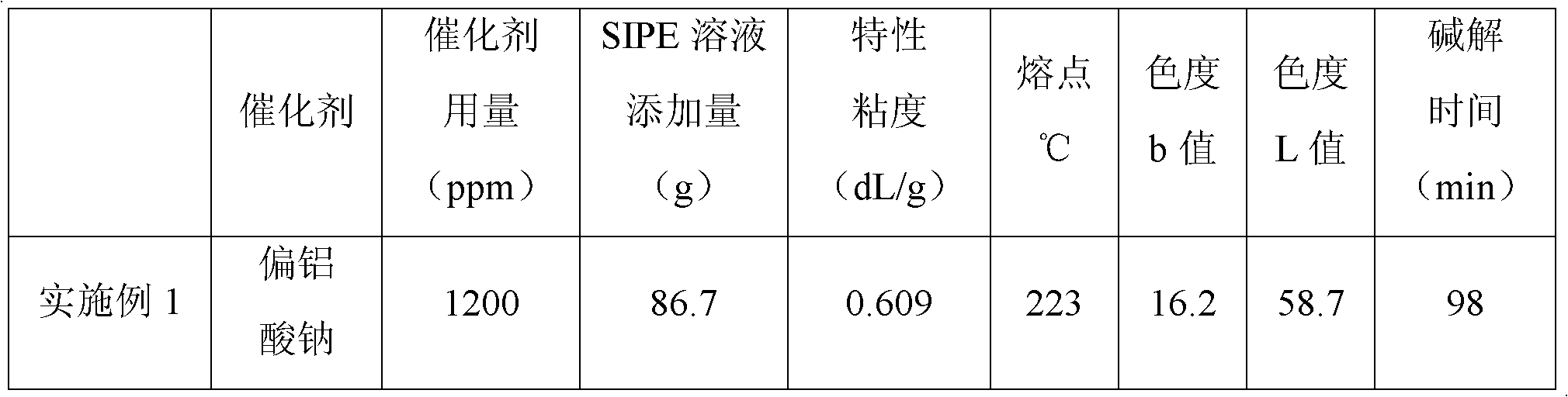

Embodiment 1

[0033] Take by weighing 25 grams of NaOH, dissolve it with deionized water to form an alkali solution with a mass concentration of 35%, put it in a heating container and heat it, and when the solution is close to boiling, add 37 grams of Al(OH) 3 , after stirring evenly, raise the temperature to about 120°C, and react for 2-3 hours to obtain a sodium aluminate solution, continue heating to make the solution boil at normal pressure and self-evaporate. When the temperature of the solution is about 150° C. by evaporation, it is cooled, crystallized and crushed to obtain a product (catalyst A) whose main component is sodium metaaluminate.

[0034] Add 250 grams of terephthalic acid and 121.5 grams of ethylene glycol into the polymerization kettle, and add 0.0375 grams of anhydrous sodium acetate to carry out the esterification reaction. The water generated, after the esterification finishes, is down to normal pressure, adding mass concentration is 86.7 grams of ethylene glycol sol...

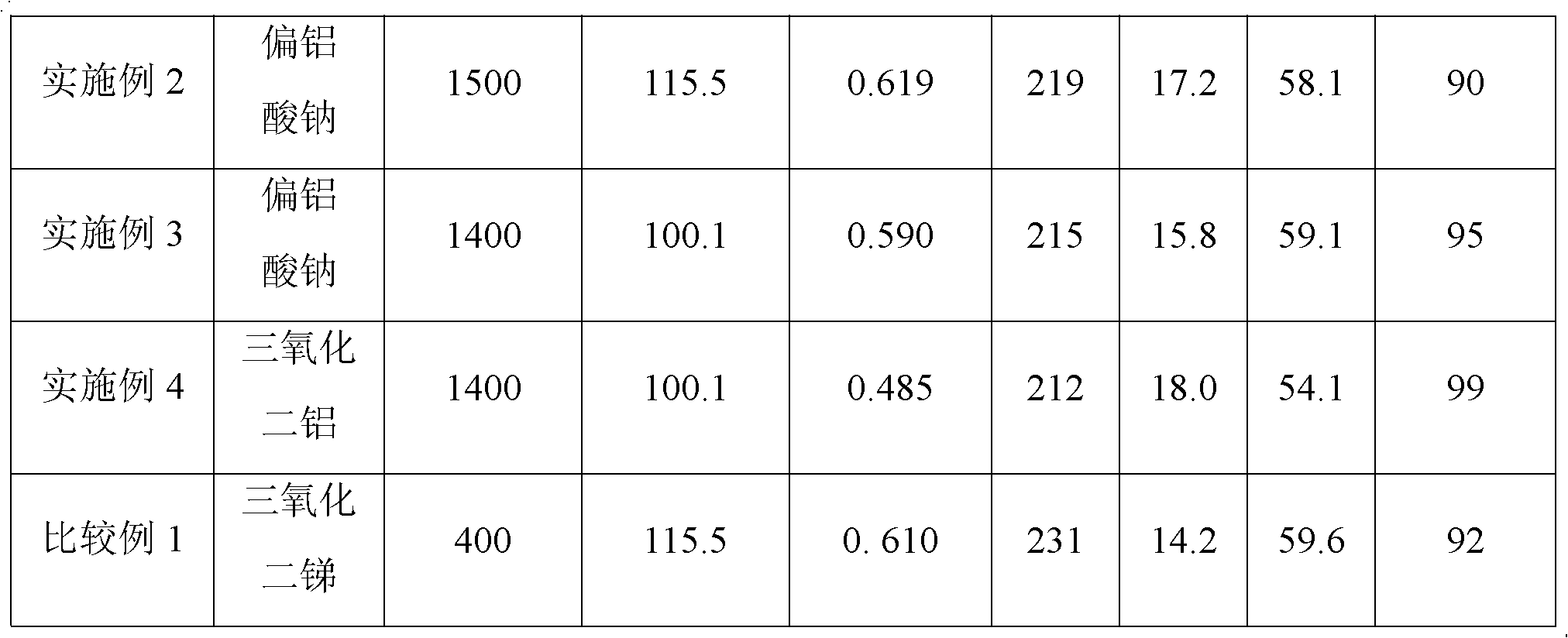

Embodiment 2

[0036]Add 250 grams of terephthalic acid and 121.5 grams of ethylene glycol into the polymerization kettle, and add 0.0375 grams of anhydrous sodium acetate to carry out the esterification reaction. The water generated, after the esterification finishes, is down to normal pressure, adding mass concentration is 115.5 grams of ethylene glycol solution of 20% bishydroxyethyl isophthalate-5-sodium sulfonate (SIPE), and the number average molecular weight is 4000 8.7 grams of polyethylene glycol and catalyst A of 0.375 grams of weight (1500ppm relative to the amount of terephthalic acid), vacuumize and decompress until the system pressure is lower than 130Pa, and the reaction temperature is gradually raised to about 280 ° C. When the system After the reaction reaches the desired viscosity, the reaction is stopped, and then the reaction product is continuously extruded from the bottom of the polymerization tank in a strip shape, cooled, and pelletized for performance testing.

Embodiment 3

[0038] Add 250 grams of terephthalic acid and 121.5 grams of ethylene glycol into the polymerization kettle, and add 0.0375 grams of anhydrous sodium acetate to carry out the esterification reaction. The water generated, after the esterification finishes, is down to normal pressure, adding mass concentration is 100.1 grams of ethylene glycol solution of 20% bishydroxyethyl isophthalate-5-sodium sulfonate (SIPE), and the number average molecular weight is 4000 8.7 grams of polyethylene glycol and catalyst A of 0.35 grams of weight (1400ppm relative to the amount of terephthalic acid), vacuumize and depressurize to a system pressure lower than 130Pa, while the reaction temperature gradually rises to about 280 ° C, when the system After the reaction reaches the desired viscosity, the reaction is stopped, and then the reaction product is continuously extruded from the bottom of the polymerization tank in a strip shape, cooled, and pelletized for performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com