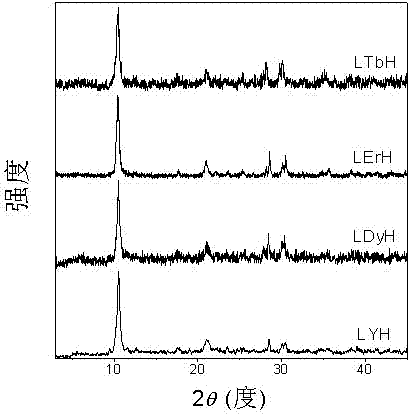

Nano lamellar compound rare-earth hydroxide and preparation method thereof

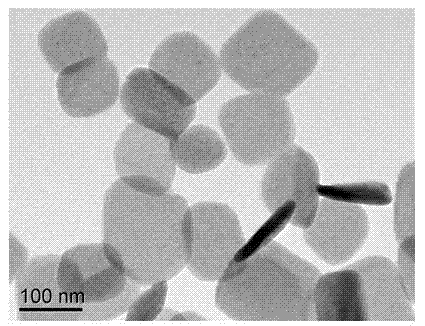

A rare earth hydroxide, layered technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of good crystal shape, good dispersion and high particle purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolve yttrium chloride and surfactant polyethyleneimine in deionized water respectively, the concentration of yttrium chloride is 0.1 mol / L, and the volume ratio of polyethyleneimine mass to solvent is 1 g:50 mL ;

[0042] (2) Add 1 mL of yttrium chloride solution, 15 mL of ethanol, and 1 mL of polyethyleneimine solution into the reaction kettle in sequence, and vigorously stir for 5 to 10 minutes at room temperature under the protection of a nitrogen atmosphere to make the solutions evenly mixed.

[0043] (3) Move the reactor into a preheated furnace for crystallization at 80 oC for 2.5 h.

[0044] (4) Allow the reactor to cool down at room temperature, centrifuge the resulting solution, wash with deionized water and absolute ethanol three times, and then dissolve in 5 mL of deionized water to obtain an aqueous solution of yttrium nanolayered hydroxide.

Embodiment 2

[0046] (1) Dissolve yttrium chloride and surfactant polyethyleneimine in deionized water respectively, the concentration of yttrium chloride is 0.5 mol / L, and the volume ratio of polyethyleneimine mass to solvent is 1 g:50 mL ;

[0047] (2) Add 1 mL of yttrium chloride solution, 15 mL of ethanol, and 5 mL of polyethyleneimine solution into the reaction kettle in sequence, and vigorously stir for 5 to 10 minutes at room temperature under the protection of a nitrogen atmosphere to make the solutions evenly mixed.

[0048] (3) Move the reactor into a preheated furnace for crystallization at 100 oC for 2.5 h.

[0049] (4) Allow the reactor to cool down at room temperature, centrifuge the resulting solution, wash with deionized water and absolute ethanol three times, and then dissolve in 5 mL of deionized water to obtain an aqueous solution of yttrium nanolayered hydroxide.

Embodiment 3

[0051] (1) Dissolve yttrium chloride and surfactant polyethyleneimine in deionized water respectively, the concentration of yttrium chloride is 0.5 mol / L, and the volume ratio of polyethyleneimine mass to solvent is 1 g:50 mL ;

[0052] (2) Add 1 mL of yttrium chloride solution, 15 mL of ethanol, and 5 mL of polyethyleneimine solution into the reaction kettle in sequence, and vigorously stir for 5 to 10 minutes at room temperature under the protection of a nitrogen atmosphere to make the solutions evenly mixed.

[0053] (3) Move the reactor into a preheated furnace for crystallization at 160 oC for 2.5 h.

[0054] (4) Allow the reactor to cool down at room temperature, centrifuge the resulting solution, wash with deionized water and absolute ethanol three times, and then dissolve in 5 mL of deionized water to obtain an aqueous solution of yttrium nanolayered hydroxide.

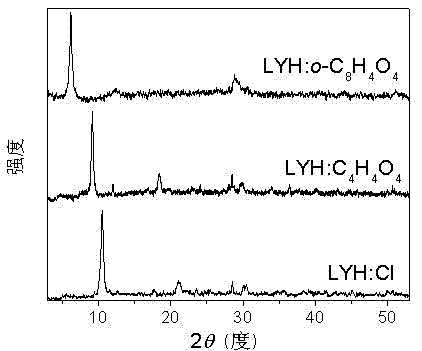

[0055] Ion exchange of yttrium nanolayered hydroxides: Typically, one part of the prepared LYH is dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com