Hypocrea for producing mesophile ethanol-tolerant beta-glucosidase highly and application of hypocrea

A technology of glucosidase and Hypocrea, applied in the directions of enzymes, fungi, microorganism-based methods, etc., can solve the problem of lack of commercial β-glucosidase, achieve the elimination of end product inhibition, reduce production costs, eliminate Inhibitory effect of cellobiose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

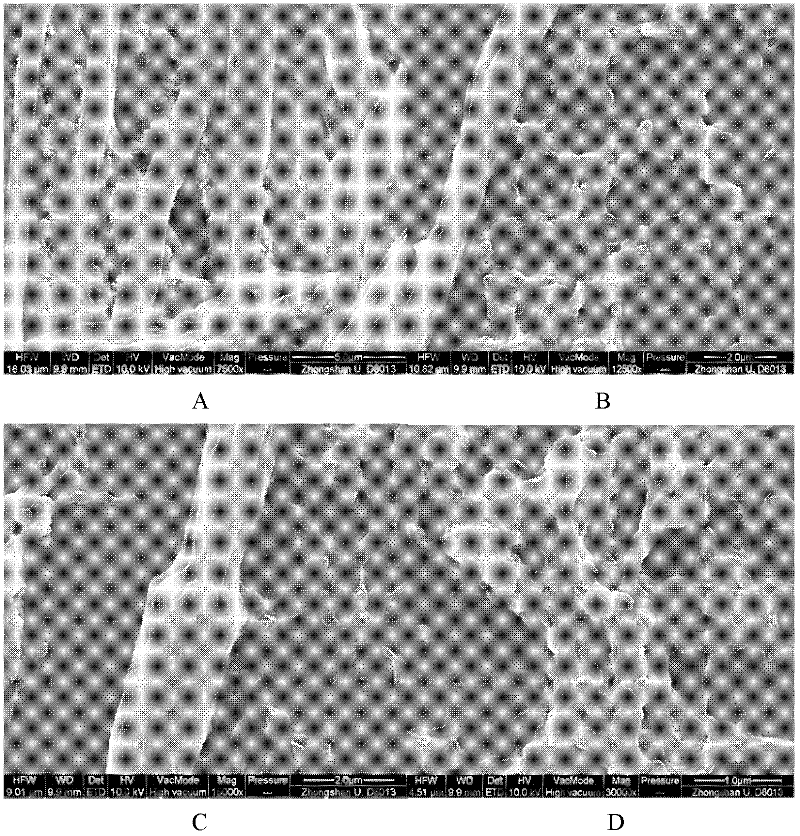

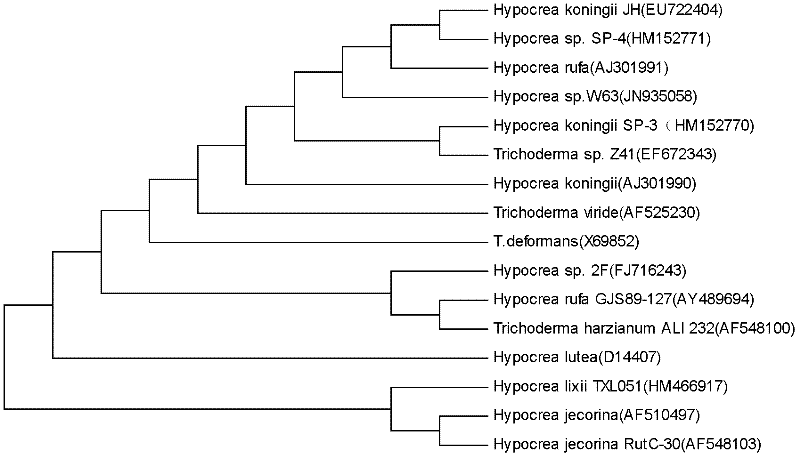

[0023] Embodiment 1: the screening of bacterial strain

[0024] Sampling dead branches and rotten leaves, soil, fungal fruiting bodies and other materials. Directly placed in the Congo red primary screening medium, the formula of the medium is: each liter of medium contains KH 2 PO 4 0.5g, (NH 4 ) 2 SO 4 2.0g, MgSO 4 ·7H 2 O 0.25g, cellulose powder (microcrystalline fiber) 2.0g, Congo red 0.2g, agar 18-20g, the balance is water, natural pH. Cultivate at 30°C for 2-5 days, pick a single colony with a large hydrolysis transparent zone and purify it on PDA medium, and store the purified strain on a PDA slant.

[0025] Re-screening for β-glucosidase activity of the strains: inoculate the purified strains preserved on the PDA slant into the same amount of re-screening fermentation medium, culture at 30°C, 120 rpm, for 48 hours. Freeze and centrifuge to take the supernatant, which is the crude enzyme solution, and use the standard pNPG method to measure the β-glucosidase a...

Embodiment 2

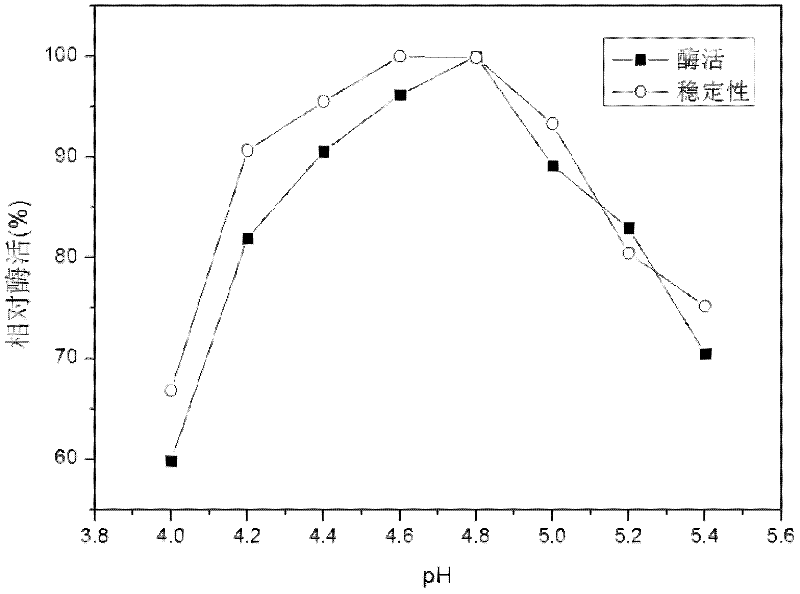

[0027] Embodiment 2: the preparation of β-glucosidase preparation and its enzyme activity, enzymatic properties assay

[0028] 1. The preparation of β-glucosidase preparation: Hypocrea sp. W63 is activated, and through seed culture, the seed culture medium is that every liter of culture medium contains 200g of potato dipping juice, 20g of glucose, and the balance is water, 115 Sterilize at ℃ for 30min. 30° C., 120 rpm, and culture for 3 days to obtain a seed culture solution. The seed culture solution is inoculated in the fermentation medium with the inoculum size of 5% (v / v), and the formula of this fermentation medium is that every liter of medium contains KH 2 PO 4 2g, (NH 4 ) 2 SO 4 2.5g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, rice straw 50g, trace element solution 200μL (CuSO 4 0.1g, MnSO 4 0.1g, FeSO 4 ·7H 2 O 0.1g, CoCl 2 0.1g, dilute to 100mL, water 100mL). 30°C, 120rpm, ferment for 5 days, then collect the fermentation broth, refrigerate and centrifuge a...

Embodiment 3

[0033] Embodiment 3: β-glucosidase is applied to simultaneous saccharification and fermentation

[0034] 1. Substrate: air-exploded straw is crushed to 60 mesh, and dried at 105°C to constant weight.

[0035] 2. Yeast was activated by culturing in YPD liquid medium at 30°C for 24 hours.

[0036] 3. Add cellulase 30 FPU / g substrate enzyme amount to the reaction system, and pre-hydrolyze at 50°C for 24 hours.

[0037] 4. Add the β-glucosidase preparation 30FPU / g substrate of Example 2 to the reaction system, inoculate the activated yeast into the reaction system at an inoculum size of 5% (v / v), ferment at 37°C, and When the yeast is inoculated, it is counted as 0h, and samples are taken at fixed points at 0, 4, 8, 12, 24, 48, 96, and 120h, and the content of ethanol and reducing sugar is detected by HPLC.

[0038] The above-mentioned reaction system is: 200mL of reaction solution in a 500mL shake flask, containing 20g of gas-exploded stalks, inorganic salt components ((NH 4 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com