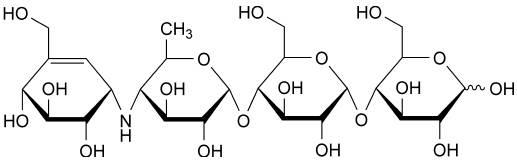

Method for preparing acarbose

A technology of acarbose and starch saccharification liquid, which is applied in the field of medicine, can solve the problems of poor effect and high cost, and achieve the effects of high fermentation level, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 7.5 kg of corn starch (sugar content 82%), add tap water to 37.5 L (concentration is 20%), adjust the pH to 5.6 after dissolving, add 3.75 g of high temperature resistant a-amylase (0.05%, calculated as corn starch ), 3.75 g of anhydrous calcium chloride (0.05%), heated to 105°C to start timing, maintained for 10 minutes, took a sample to measure DE=17, cooled to 60°C, added 0.06% of starch mass of pullulanase, 0.06% Fungal enzyme, 0.25% β-amylase, maintained at 59°C for 8 hours, sampling and testing, the total amount of compound maltose was 5.3 kg, and the conversion rate was 86.2% relative to the total sugar content of corn starch. Preparation of fermentation medium: take 29 L of starch saccharification solution (equivalent to 4.1 kg of maltose, proportion 6.8%), other nutrients include 2.6% glucose, 1.0% soybean cake powder, 0.5% monosodium glutamate, 0.7% glycerin, 0.3% C a CO 3 and 0.03% F e Cl 3 , put into a 100L fermentation tank, prepare 60 L of ferment...

Embodiment 2

[0021] Weigh 12 kg of potato starch (sugar content 70%), add tap water to 40 L (concentration is 30%), adjust the pH to 6.2 after dissolving, add 0.2% (calculated as corn starch) high temperature resistant a-amylase, 0.02% Anhydrous calcium chloride, start timing when heated to 110°C, maintain for 5 minutes, take a sample to measure DE=11, cool down to 60°C, add 0.2% pullulanase, 0.2% fungal enzyme, 0.45% β-amylase by starch quality, The temperature was kept at 55°C for 4 hours. Sampling and detection showed that the total amount of maltose in the starch saccharification solution was 7.98 kg, the conversion rate was 95.0%, and the amount of glucose in the saccharification solution was 97 g. Preparation of fermentation medium: take 20 L of starch saccharification liquid (equivalent to 6.4 kg of maltose, proportion 10.6%), other nutrients include 2.4% glucose, 1.0% soybean cake powder, 0.5% monosodium glutamate, 0.6% glycerin, 0.5% C a CO 3 and 0.05% F e Cl 3 , put into a 100...

Embodiment 3

[0023] Weigh 5500 kg of corn starch (sugar content 85%) and add tap water to 13.75 m 3 (Concentration is 40%), adjust the pH to 6.0 after dissolving, add 5.5 kg of 0.1% (calculated as corn starch) high temperature-resistant a-amylase, 4.4 kg of 0.08% anhydrous calcium chloride, heat to 105°C to start timing, and maintain For 5 minutes, take a sample to measure DE=13, cool down to 60°C, add 0.1% pullulanase, 0.1% fungal enzyme, and 0.3% β-amylase by starch quality, maintain at 58°C for 4 hours, take a sample for detection, maltose in the starch saccharification solution The total amount is 4146.8 kg, relative to the total sugar content of cornstarch, the conversion rate is 88.7%, and the glucose content in the saccharification solution is 62 kg. Preparation of fermentation medium: take 8 m 3 Starch saccharification liquid (equivalent to 3402.5 kg maltose, ratio 8.5%), other nutrients include 1.8% glucose, 1.0% soybean cake powder, 0.5% monosodium glutamate, 0.6% glycerin, 0.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com