Hydrophilic poly-beta-hydroxybutyrate (PHB) fiber and preparation method thereof

A technology of hydrophilic and hydrophilic polymers, applied in the direction of conjugated synthetic polymer artificial filaments, etc., can solve the problems of poor hydrophilicity and long degradation cycle of PHB fibers, and achieve improved hydrophilicity and degradation rate, The preparation process is simple and the interface effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

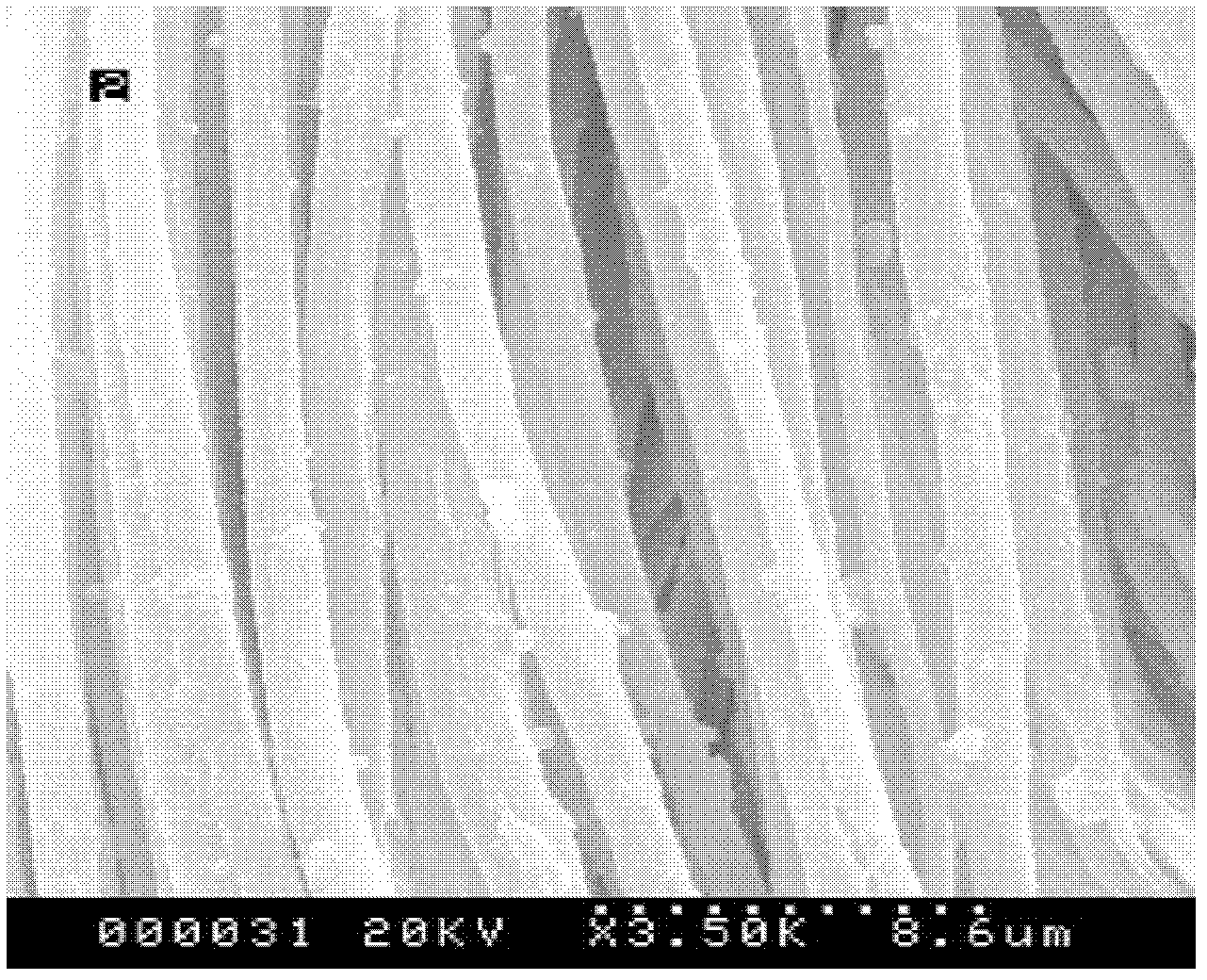

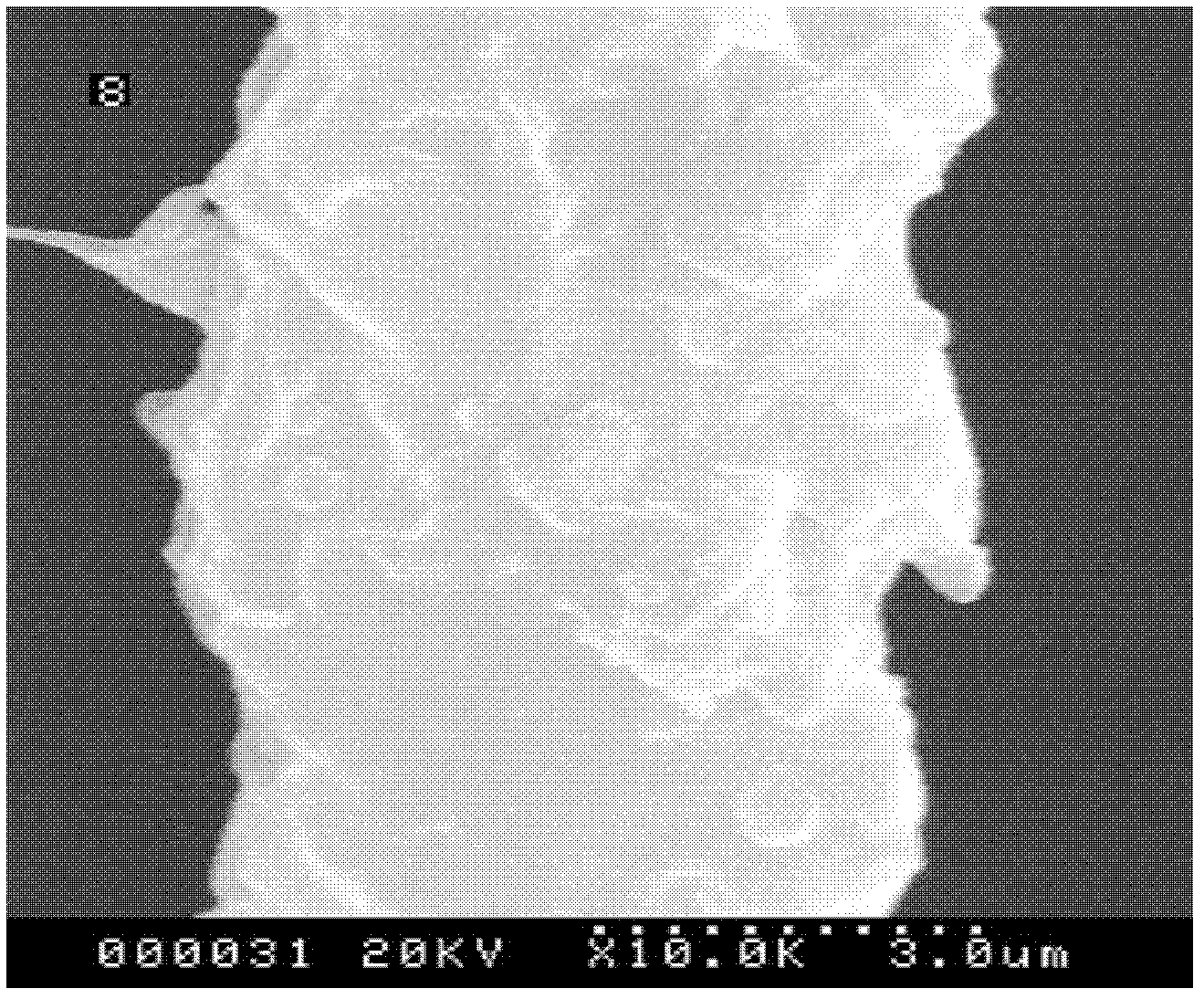

Image

Examples

Embodiment 1

[0031] The hydrophilic PHB fiber of this embodiment is made by mixing and spinning the following raw materials in mass percentage: 20% hydrophilic polymer and 80% PHB; the hydrophilic polymer is polyacrylamide; The viscosity-average molecular weight of the PHB is 1.5×10 5 , the mass purity is above 99%.

[0032] The preparation method of this embodiment is:

[0033] Step 1, 2 grams of hydrophilic polymers are dissolved in 200 milliliters of organic solvents, and stirred to completely dissolve the hydrophilic polymers to obtain a transparent solution with a hydrophilic polymer concentration of 10 g / L; the organic solvent is Trichloroethane;

[0034] Step 2, add 8 grams of PHB to the solution described in step 1, then add 800 milliliters of trichloroethane, stir to make the PHB dissolve completely, and obtain a spinning solution with a total mass concentration of solute of 0.7%;

[0035] Step 3, the spinning solution described in step 2 is left standing for degassing, and the...

Embodiment 2

[0041] The present embodiment is the same as embodiment 1, wherein the difference is: the hydrophilic polymer is methacrylic acid copolymer, polyacrylic acid, polyethylene glycol, polyoxyethylene, polyvinyl alcohol or polyvinylpyrrolidone; Described organic solvent is ethylene dichloride, chloroform, methylene dichloride or carbon tetrachloride.

Embodiment 3

[0043] The hydrophilic PHB fiber of this embodiment is made by mixing and spinning the following raw materials in mass percentage: 14.3% hydrophilic polymer, 28.6% PLLA and 57.1% PHB; the hydrophilic polymer is poly Ethylene glycol; The viscosity-average molecular weight of described PLLA is 0.5 * 10 5 , the mass purity is more than 99%; the viscosity-average molecular weight of the PHB is 6.5×10 5 , the mass purity is above 99%.

[0044] The preparation method of this embodiment is:

[0045] Step 1, 5 grams of hydrophilic polymers are dissolved in 600 milliliters of organic solvents, and stirred to completely dissolve the hydrophilic polymers to obtain a transparent solution with a hydrophilic polymer concentration of 8.3 g / L; the organic solvent is carbon tetrachloride;

[0046] Step 2, add 20 grams of PHB and 10 grams of PLLA to the solution described in step one, then add 400 milliliters of carbon tetrachloride, stir to make PHB and PLLA dissolve completely, and obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com