Method for measuring protein nitrogen content in tobaccos

A determination method and technology for nitrogen content, which are applied in biological testing, preparation of test samples, material inspection products, etc., can solve the inaccurate results of protein nitrogen content determination, incomplete and incomplete digestion, and affect the digestion of nitrogen-containing components. and other problems, to achieve the effect of high accuracy, simple steps, and short processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

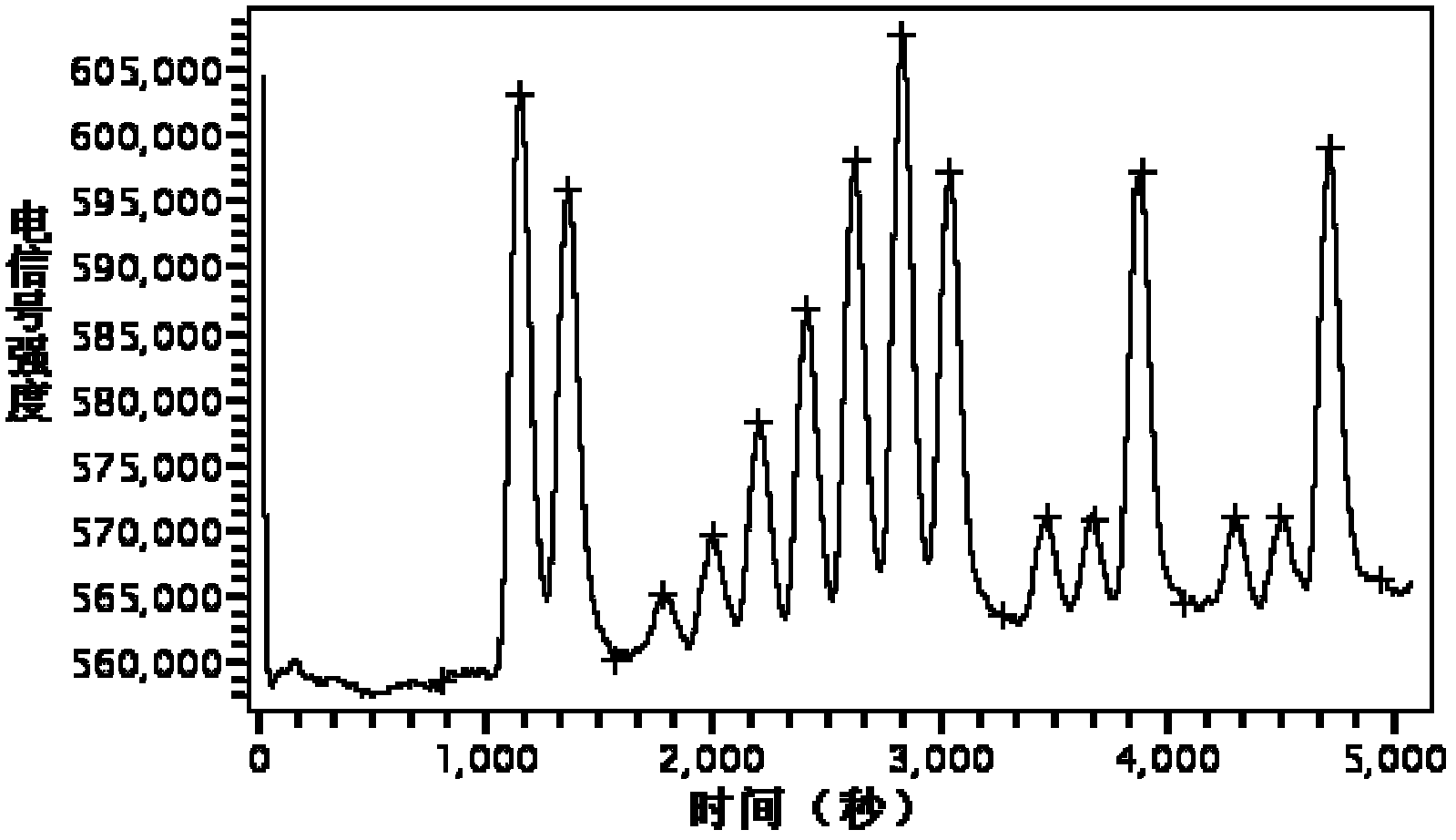

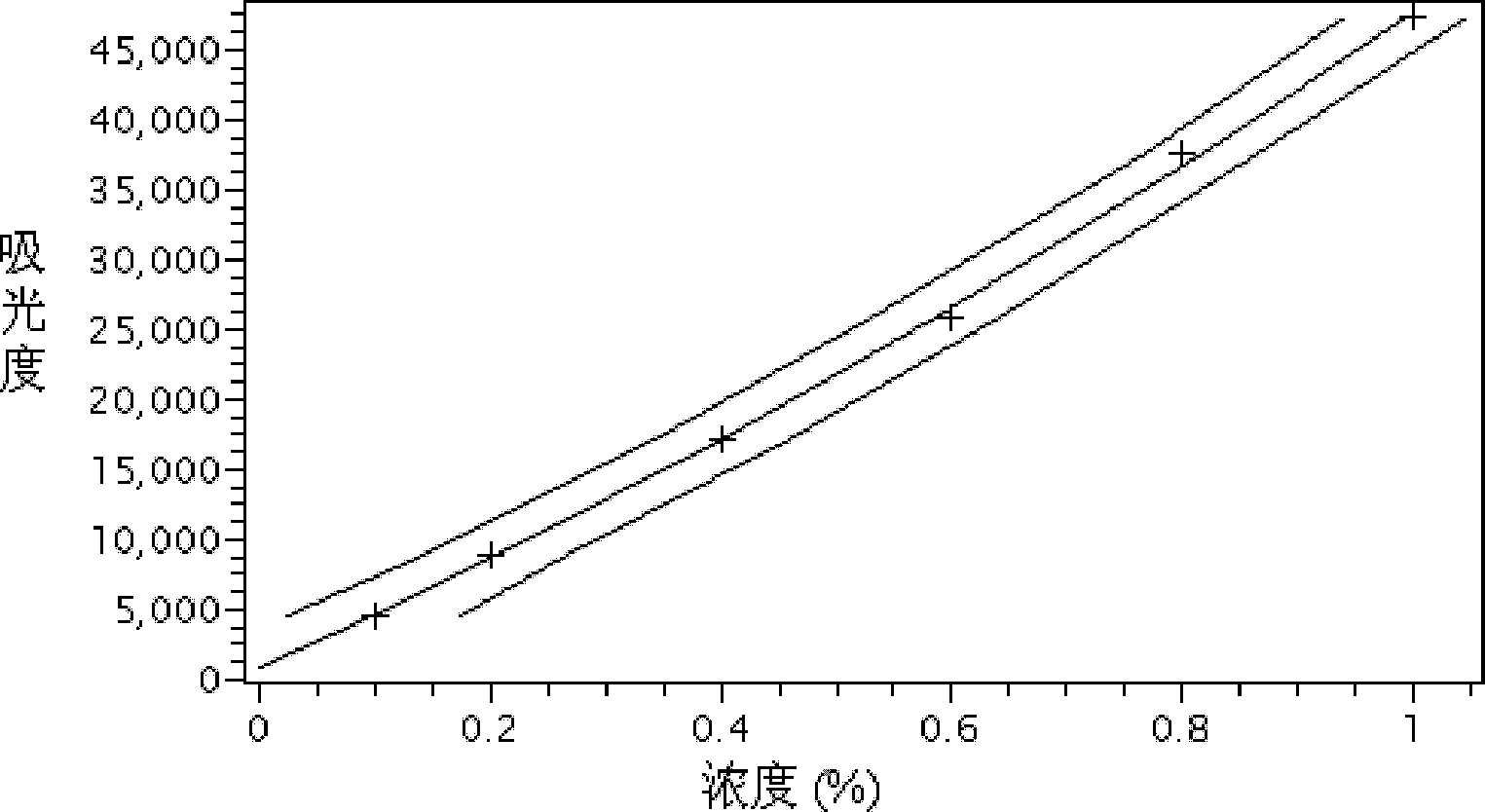

[0069] 11 g of sodium nitrate was dissolved in 100 mL of distilled water to obtain a sodium nitrate stock solution with a mass concentration of 10.0%. Accurately pipette 1.0mL, 2.0mL, 4.0mL, 6.0mL, 8.0mL, 10.0mL of the standard stock solution, and use 0.5% acetic acid solution to dilute it to 100mL respectively to obtain a series of sodium nitrate standards solution to be tested. Take 2 mL of the standard solution to be tested respectively, pour it into the sample tube of the continuous flow analyzer and measure it in parallel three times respectively, and get the average value. In the continuous flow analyzer, the sample injection volume is 0.1mL / min, the injection time is 100s, and the flushing time is 120s. First at 90°C, add 2mL of potassium persulfate solution with a molar concentration of 0.3mol / L in the standard solution to be tested, the injection volume of potassium persulfate solution is 0.8mL / min, then the mixed solution obtained at 90 ℃, under the acidic conditio...

Embodiment 2~17

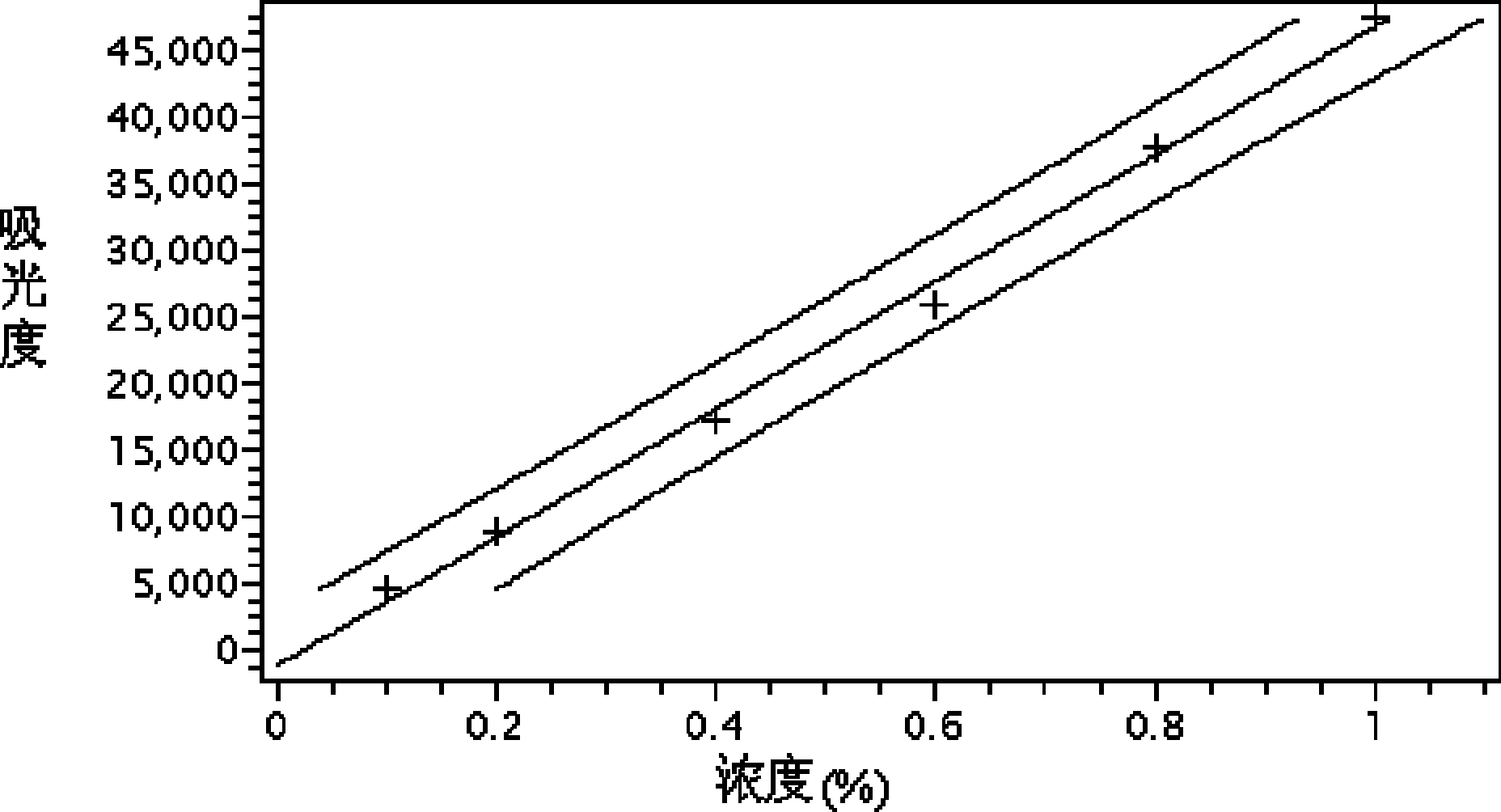

[0075] According to the standard GB / T19616-2004 of the People's Republic of China, 16 kinds of tobacco samples were selected. The tobacco samples were the flue-cured tobacco leaf samples produced at home and abroad in 2006, 2007 and 2008 provided by the tobacco leaf group of the raw material inspection room of the company's technology center. According to the standards of the People's Republic of China Tobacco industry standard YC / T31-1996 prepares tobacco dust samples and determines the moisture content in the tobacco dust. Dissolve 2g of smoke powder sample in 100mL of 0.5% acetic acid solution by volume fraction, heat to boil for 15 minutes, filter quickly with nitrogen-free qualitative filter paper, wash the precipitate with 0.5% acetic acid solution by volume fraction, combine the obtained filtrates, After cooling, set the volume to 200mL, accurately pipette 2mL of the filtrate and pour it into the sample tube of the continuous flow analyzer for three parallel measurements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com