Transparent conductive film and preparation method of transparent conductive film

A technology of transparent conductive film and conductive layer, which is applied to conductive layers on insulating carriers, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high production cost of carbon nanotubes, limited practical application, etc. The effect of strong sex and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

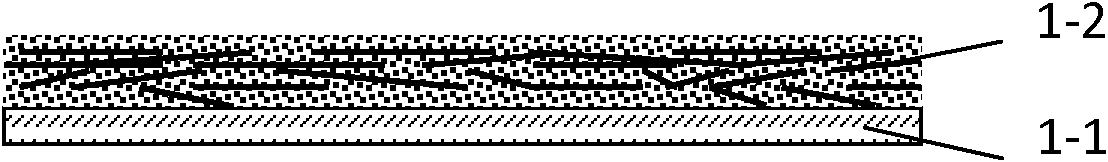

[0040] This embodiment is used to prepare a-type transparent conductive film.

[0041] (1) Graphene oxide was prepared by chemical oxidation: 5 g of graphite and 4 g of sodium nitrate (analytical pure) were added to the flask, and then 300 mL of concentrated sulfuric acid (analytical pure) was added. Stir the flask at 0°C (ice-water bath), and slowly add 22.5g of potassium permanganate (analytical pure) within 1h, then keep it at 0°C for 4h, then raise the temperature to 35°C, and continue stirring for 5 days , the reaction solution changed from dark green to dark brown viscous liquid. Under the condition of stirring, the reacted liquid was slowly added into 500mL of water, then the temperature was raised to 95°C and stirring was continued at this temperature for 30min, and then the temperature was lowered to 60°C. Add 30 mL of hydrogen peroxide (aqueous solution with a mass concentration of 10%), continue to stir and react for 2 h, and then cool down to room temperature. Th...

Embodiment 2-10

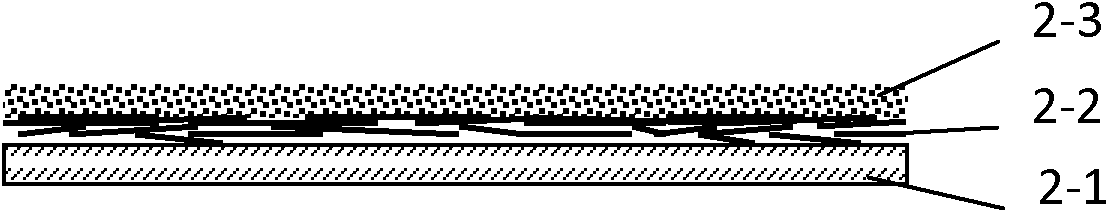

[0048] This embodiment is used to prepare a-type transparent conductive film.

[0049] The a-type transparent conductive films P2-P10 were prepared according to the method of Example 1. Conditions and characterization results are shown in Table 1, C / MO represents the weight ratio of graphene and metal oxide, C concentration represents the concentration of graphene, and MO concentration represents the concentration of metal oxide, where the unit of concentration is mg / mL , the unit of sheet resistance is Ω / sq; the processing conditions used for spin-coating each layer are spin-coating at 25°C with a spin coater at a speed of 2000r / min for 60 seconds, drying at 80°C for 40min, and then drying at 140°C for 10min ; After 90-degree bending test, after bending 500 times, the conductivity of P2-P10 has no obvious change.

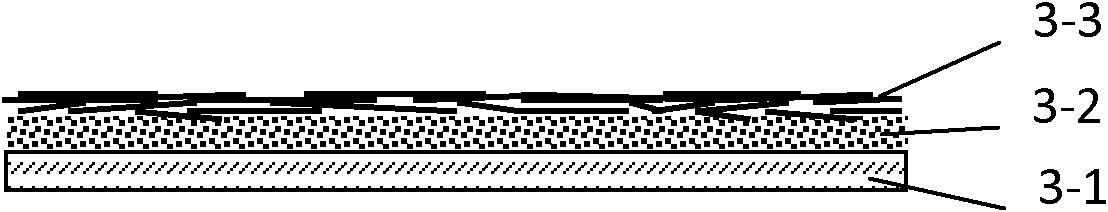

Embodiment 11-20

[0051] This embodiment is used to prepare a-type transparent conductive film.

[0052] The a-type transparent conductive films P11-P20 were prepared according to the method of Example 1. Conditions and characterization results are shown in Table 1, C / MO represents the weight ratio of graphene and metal oxide, C concentration represents the concentration of graphene, and MO concentration represents the concentration of metal oxide, where the unit of concentration is mg / mL , the unit of sheet resistance is Ω / sq; the processing conditions for spin-coating each layer are: use a spin coater at 2000r / min speed for 60 seconds at 25°C, dry at 120°C for 20min, and then dry at 160°C 2min; After 90-degree bending test, after bending 500 times, the conductivity of P11-P20 has no obvious change.

[0053] Table 1

[0054]

[0055] It can be seen from Table 1 that the transparent conductive film of the present invention has high light transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com