Carbon material-loading manganese dioxide nanowire array composite and method for producing same

The technology of manganese dioxide nanometer and composite material is applied in the field of manganese dioxide composite material and its preparation, and can solve the problems of affecting the electrochemical high-current charge and discharge performance, easy agglomeration of manganese dioxide particles, limitation of fast charge and discharge capacity, and the like, Achieve the effect of superior electrochemical performance, curb agglomeration phenomenon, and facilitate popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

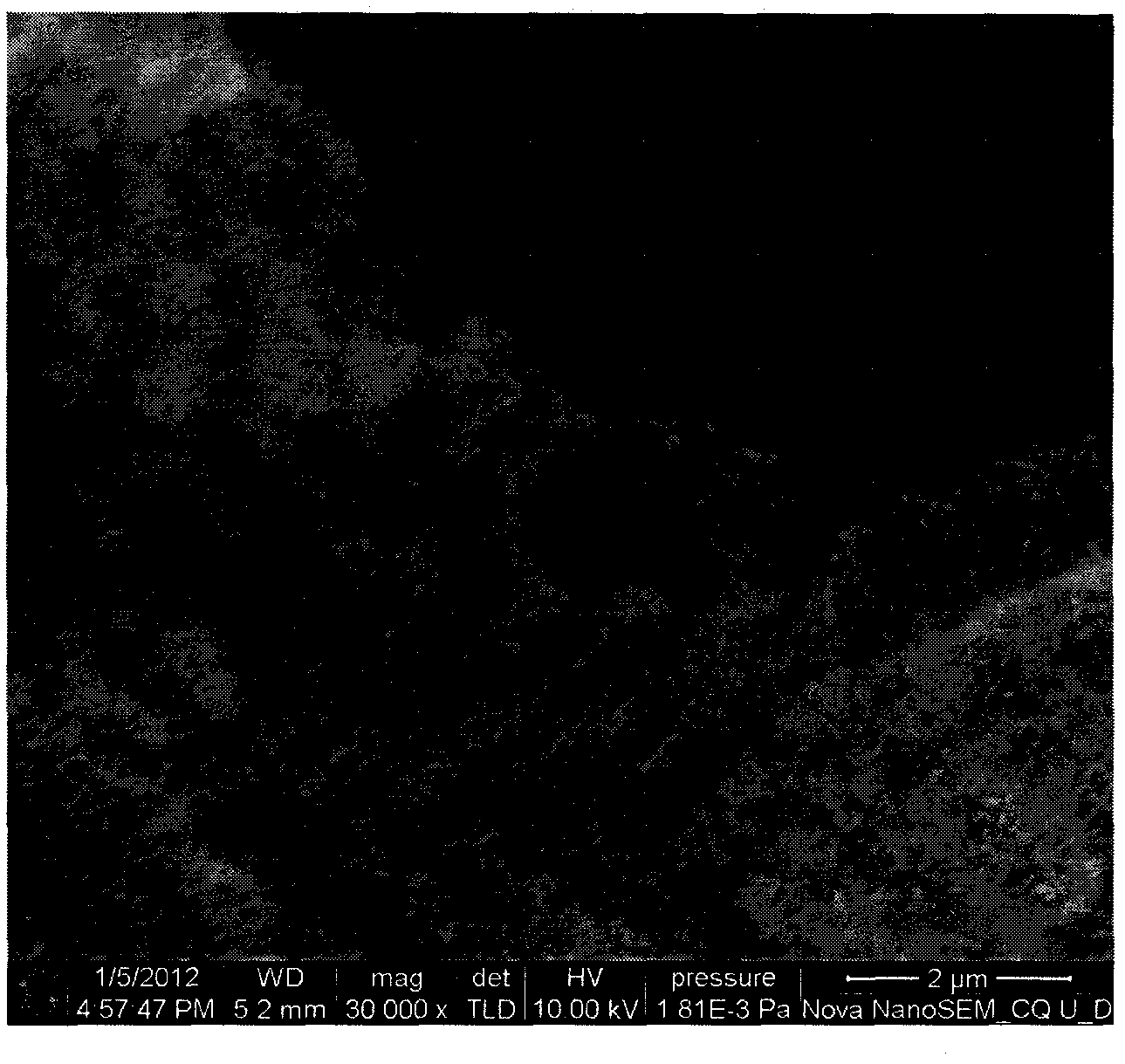

Image

Examples

Embodiment 1

[0025] A carbon material loaded manganese dioxide nanowire array composite material and its mass percentage are:

[0026] Carbon material 10%

[0027] Manganese Dioxide 90%

[0028] Wherein: the carbon material is graphene.

[0029] A method for preparing a carbon material-supported manganese dioxide nanowire array composite material, the specific steps of which are as follows:

[0030] (1) Prepare mixed solution

[0031] With carbon material and potassium permanganate as raw material, according to the quality (g) of carbon material: the quality (g) of potassium permanganate: the ratio of the volume (ml) of deionized water is the ratio of 1: 20: 2000, will The carbon material and potassium permanganate were added into deionized water, and mixed and stirred at room temperature for 30 minutes to obtain a mixed solution of the carbon material and potassium permanganate (ie, a precursor solution).

[0032] Wherein: the carbon material is graphene.

[0033] (2) redox reaction ...

Embodiment 2

[0038] A carbon material loaded manganese dioxide nanowire array composite material and its mass percentage are:

[0039] Carbon material 20%

[0040] Manganese Dioxide 80%

[0041] Wherein: the carbon material is graphite.

[0042] A preparation method of carbon material loaded manganese dioxide nanowire array composite material, same as embodiment 1, wherein:

[0043] In step (1), the mass (g) of carbon material: the mass (g) of potassium permanganate: the volume (ml) of deionized water is 1: 1: 100, and stirred for 3 minutes. Wherein: the carbon material is graphite.

[0044]In the (2) step, according to the mixed solution that the (1) step makes: the volume ratio of the sulfuric acid that mass concentration is 98% is the ratio of 1: 0.01, and sulfuric acid is added to the mixed solution that (1) step makes , the oxidation-reduction reaction was carried out with stirring at 25°C for 600 minutes.

[0045] In the (3) step, the mass (g) of solid matter: the volume (mL) ra...

Embodiment 3

[0047] A carbon material loaded manganese dioxide nanowire array composite material and its mass percentage are:

[0048] Carbon material 40%

[0049] Manganese Dioxide 60%

[0050] Wherein: the carbon material is carbon fiber.

[0051] A preparation method of carbon material loaded manganese dioxide nanowire array composite material, same as embodiment 1, wherein:

[0052] In step (1), the mass (g) of carbon material: the mass (g) of potassium permanganate: the volume (ml) of deionized water is 1: 100: 3000, and stirred for 60 minutes. Wherein: the carbon material is carbon fiber.

[0053] In the (2) step, according to the mixed solution that the (1) step makes: the volume ratio of the sulfuric acid that mass concentration is 98% is the ratio of 1: 0.04, adds sulfuric acid to the mixed solution that the (1) step makes , the oxidation-reduction reaction was carried out at 100°C for 300 minutes with stirring.

[0054] In step (3), the mass (g) of solid matter: the volume (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com