Fluorination grapheme-lithium vanadium phosphate composite material, as well as preparation method and application thereof

A technology of vanadium lithium fluorophosphate and fluorinated graphene, which is applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low conductivity and stability of fluorinated graphite materials, and poor high-current performance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

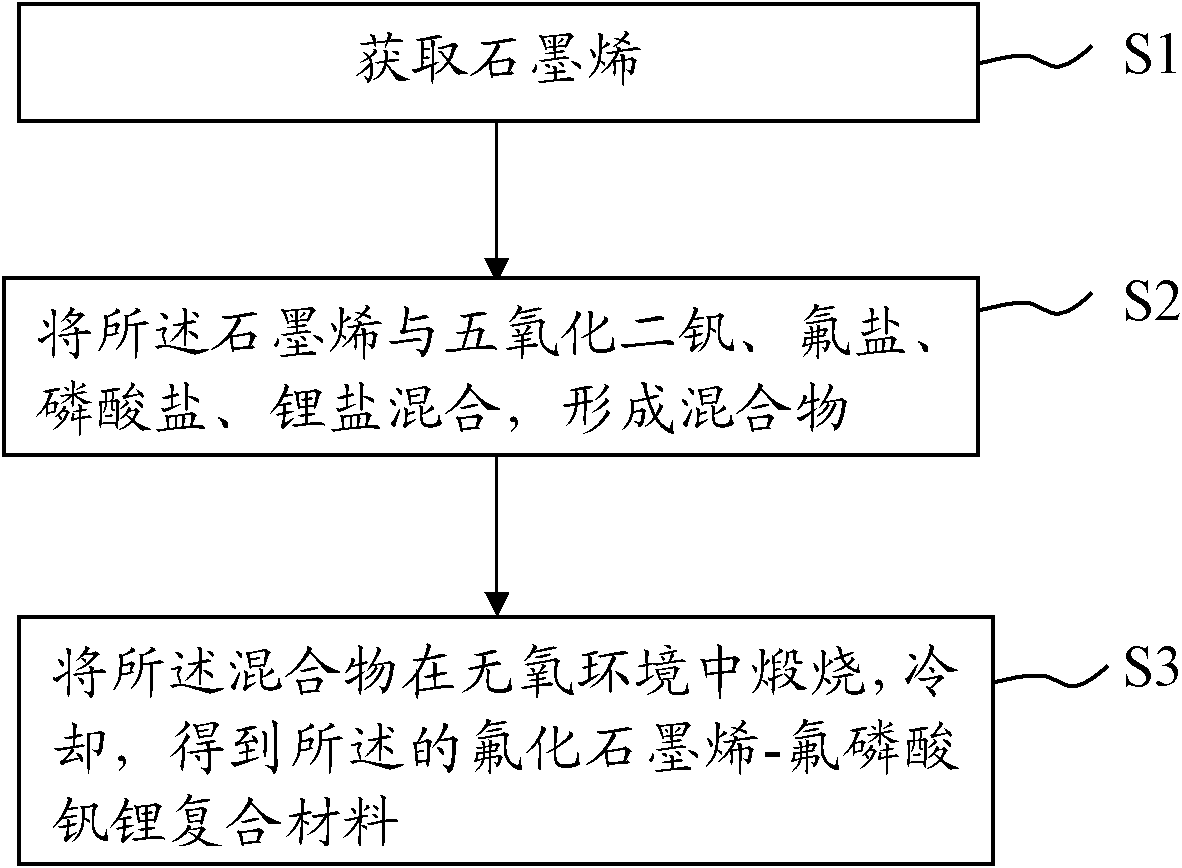

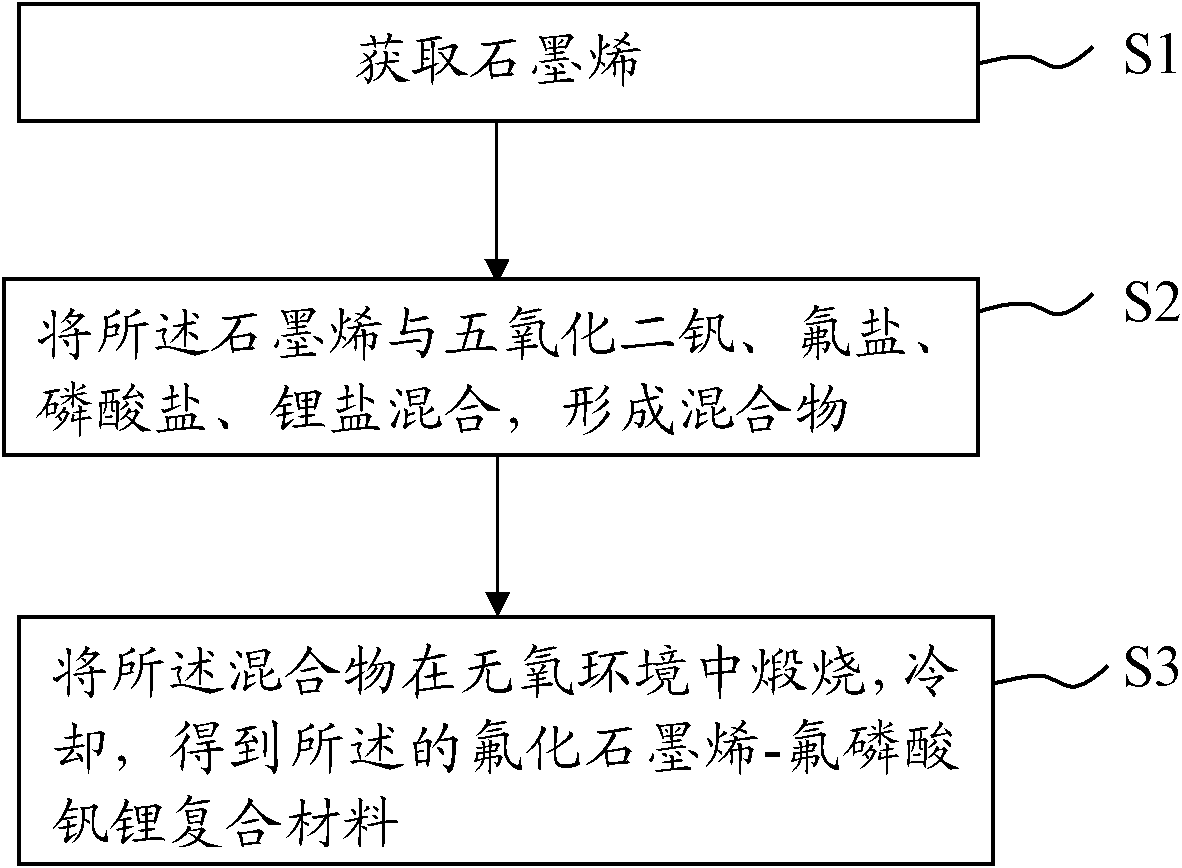

[0018] The embodiment of the present invention provides a method for preparing a fluorinated graphene-lithium vanadium phosphate composite material which is simple in process, low in cost and suitable for industrial production. For the process flow of the preparation method of the fluorinated graphene-lithium vanadium phosphate composite material, please refer to figure 1 , the method includes the following steps:

[0019] S1: Obtain graphene;

[0020] S2: mixing the graphene with vanadium pentoxide, fluoride salt, phosphate salt, and lithium salt to form a mixture;

[0021] S3: Calcining and cooling the mixture in an oxygen-free environment to obtain the fluorinated graphene-lithium vanadium phosphate composite material.

[0022] Specifically, in the S1 step of the above-mentioned fluorinated graphene-lithium vanadium phosphate composite material preparation method, the graphene acquisition method is preferably as follows:

Embodiment 1

[0033] The preparation of fluorinated graphene-lithium vanadium phosphate composite material, its method technological process is as follows:

[0034] S11: Preparation of graphene: graphene was prepared by the improved Hummers method;

[0035] S111: Graphite oxide: Graphene oxide is prepared by the improved Hummers method; the specific steps are: add 20g of graphite powder (50 mesh), 10g of potassium persulfate and 10g of phosphorus pentoxide to concentrated sulfuric acid at 80°C, and stir evenly , cooled for more than 6 hours, then filtered, washed until neutral, dried, and added the dried sample to 0°C, 230ml of concentrated sulfuric acid, then added 60g of potassium permanganate, and kept the temperature below 20°C, then in After keeping in an oil bath at 35°C for 2 hours, slowly add 920ml of deionized water, and after 15 minutes, continue to add 2.8L of deionized water (which contains 50ml of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow,...

Embodiment 2

[0045] The preparation of fluorinated graphene-lithium vanadium phosphate composite material, its method technological process is as follows:

[0046] S21: Preparation of graphene: prepare graphene by improved Hummers method;

[0047] S211: graphite oxide: refer to the S111 step in embodiment 1;

[0048] S212: Preparation of graphene: Add 100 mg of graphene oxide prepared in step S21 and 100 ml of deionized water into a 250 ml round-bottomed flask. At this time, the solution is a brownish yellow suspension, and then the suspension is treated with a 150W ultrasonic wave Ultrasonic dispersion, followed by adding ethylenediamine (1ml, 98%) and heating to 100°C for 24-48h, then filtering, washing with 300ml of water and 300ml of methanol in turn, drying in a vacuum oven at 80°C for 48h, to obtain Graphene;

[0049] S22: Preparation of fluorinated graphene and lithium vanadium phosphate composite: take 0.095mol of V 2 o 5 Powder, 0.2mol LiAC, 0.2mol NH 4 h 2 PO 4 , 20g of gr...

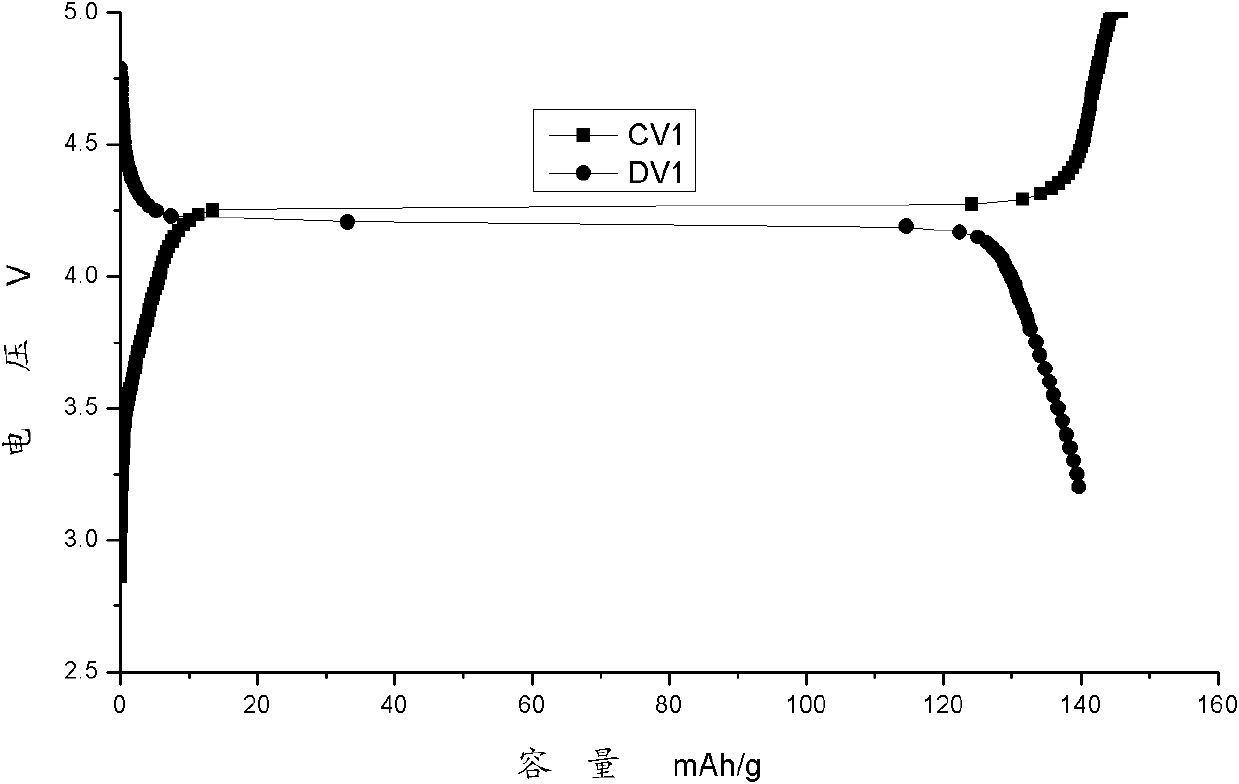

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com