Method for preparing lithium ion battery cathode material with layered structure

A lithium-ion battery and cathode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as unfavorable environmental protection, environmental pollution, equipment damage, etc., achieve high industrial industrialization value, reduce production costs, and recycle at one time high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

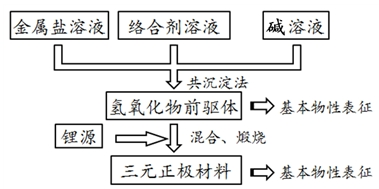

Method used

Image

Examples

Embodiment 1

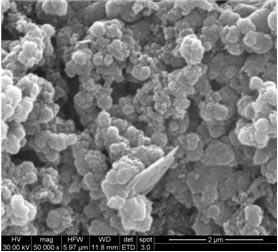

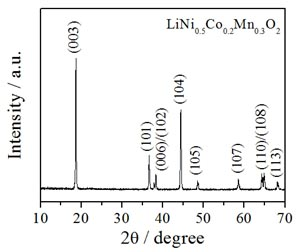

[0032] Prepare a mixed solution of nickel, cobalt, and manganese sulfate with a metal cation concentration of 1.5mol / L, wherein the molar ratio of nickel, cobalt, and manganese is 5:2:3, prepare 2.5mol / L lactic acid solution and 2mol / L L of sodium hydroxide solution. Adjust the flow rate of the sulfate mixed solution and the lactic acid solution so that the molar ratio of the metal cation to the complexing agent is 2:3. The pH value of the reaction solution is adjusted to 11 by sodium hydroxide solution, and the reaction temperature is 70 o C, the stirring speed is 400rpm. 70 o C aging at constant temperature for 8 hours. After the reaction product was washed by centrifugation, after 80 o After C vacuum drying, the hydroxide precursor of the positive electrode material was obtained with a specific surface area of 26.9 m 2 / g, the tap density is 1.54g / cm 3 ; Then the precursor and Lithium Carbonate are mixed evenly with the molar ratio of 1:1, 400 o After pre-burni...

Embodiment 2

[0034] Prepare a mixed solution of nickel, cobalt, and manganese sulfate with a metal cation concentration of 2.5mol / L, wherein the molar ratio of nickel, cobalt, and manganese is 1:1:1, prepare 1mol / L sodium lactate solution and 3mol / L of sodium hydroxide solution. Adjust the flow rate of the sulfate mixed solution and the lactic acid solution so that the molar ratio of the metal cation to the complexing agent is 1:1. The pH value of the reaction solution is adjusted to 12 by sodium hydroxide solution, and the reaction temperature is 65 o C, the stirring speed is 250rpm. 65 o C aging at constant temperature for 10 hours. After the reaction product was washed by centrifugation, after 60 o After vacuum drying, the hydroxide precursor of the positive electrode material was obtained with a specific surface area of 24.3m 2 / g, the tap density is 1.75g / cm 3 ; Then the precursor and Lithium Retard are mixed with the ratio of 1:1.15 in molar ratio, after 4 hours with 300rpm b...

Embodiment 3

[0036] Prepare a mixed solution of nickel and manganese sulfate with a metal cation concentration of 2 mol / L, wherein the molar ratio of nickel and manganese is 1:1, prepare 5 mol / L sucrose solution and 5 mol / L sodium hydroxide solution. Adjust the flow rate of the sulfate mixed solution and the sucrose solution so that the molar ratio of the metal cation to the complexing agent is 0.5:1. The pH value of the reaction solution is adjusted to 11.5 by sodium hydroxide solution, and the reaction temperature is 75 o C, the stirring speed is 350rpm. 75 o C aging at constant temperature for 10 hours. After the reaction product was washed by centrifugation, after 60 o After C vacuum drying, obtain the hydroxide precursor of positive electrode material; Then precursor and Lithium Retard are with the ratio of molar ratio 1:1.5, mix after 4 hours with 300rpm ball mill, 400 o After pre-burning at C for 3 hours, 1000 o C was sintered for 4 hours, and passed through a 400-mesh sieve af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com