Tissue engineering scaffold material of chemical bonding active material and preparation method thereof

A tissue engineering scaffold and technology of active substances, applied in the field of biological scaffold materials and their preparation, can solve the problems of limited application, lack of hydrophobicity and lack of signal for cell recognition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

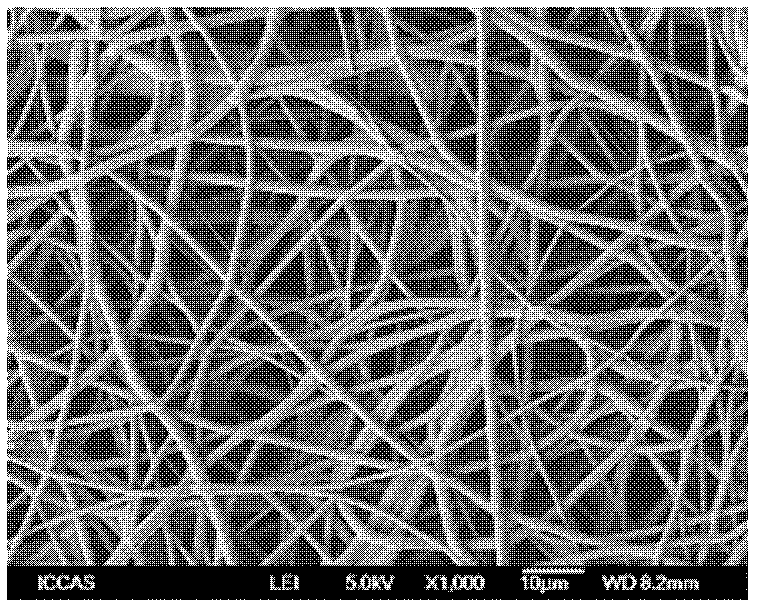

[0046] (1) Configuration of polymer spinning solution: PCL (molecular weight: 100,000) and collagen (molecular weight: 100,000) are mixed and dissolved in trifluoroethanol to prepare a polymer spinning solution with a total concentration of 12w / v%. , wherein the mass ratio of PCL to collagen is 60:40;

[0047] (2) Preparation of nanofiber membrane material: the polymer spinning liquid obtained in step (1) is loaded into the liquid storage device of a single-nozzle electrospinning equipment for electrospinning, and the electrospinning process parameters are: static voltage is 20kV; The feeding rate is 50ul / min, the receiving distance is 15cm; the ambient temperature is 20°C, and the polymer fiber membrane material is collected on the collector, and the average diameter of the fiber is 550nm.

[0048] (3) Soak the polymer fiber membrane material obtained in step (2) into a mixed solution of 80 / 20 ethanol and water containing 100mM carbodiimide, cross-link the GE component, and r...

Embodiment 2

[0052] (1) Configuration of polymer spinning solution: dissolve PLGA (molecular weight: 100,000) in a mixed solvent of 80 / 20 DMF and acetone to obtain a PLGA solution with a concentration of 12w / v%; dissolve hyaluronic acid and gelatin In a 90 / 10 mixed solvent of ethanol and water, a mixed solution with a concentration of 5w / v% and a mass ratio of hyaluronic acid and gelatin of 30 / 70 is prepared.

[0053] (2) Preparation of nanofiber membrane material: use a multi-nozzle spinning device, fill the mixed solutions of PLGA solution, hyaluronic acid and gelatin into different infusion channels for electrospinning, and the electrospinning process parameters are: The voltage is 25kV; the feeding rate is 20ul / min, the receiving distance is 8cm; the ambient temperature is 50°C, and the polymer fiber membrane material is obtained on the collector, and the diameter of the fiber is between 250-1000nm.

[0054] (3) Soak the fibrous membrane obtained in step (2) into a mixed solution of 80...

Embodiment 3

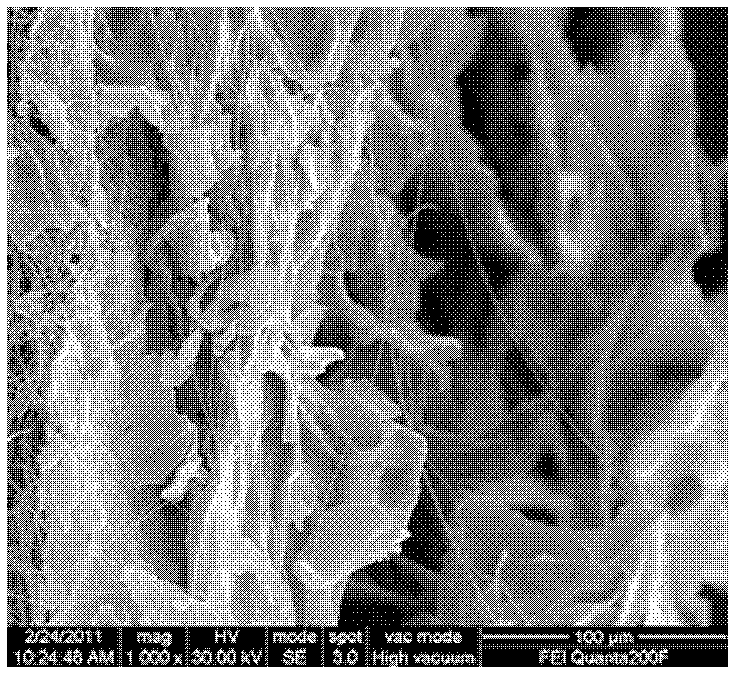

[0058] (1) Preparation of synthetic polymer nanofiber membrane: PCL is dissolved in the mixed solvent of DMF and methanol of 80 / 20, and is prepared into a PCL solution with a concentration of 12W / V% for electrospinning. The electrospinning process parameters are: The static voltage is 15kV; the feeding rate is 10ul / min, the receiving distance is 8cm; the ambient temperature is 20°C, and a 2-6mm thick PCL nanofiber membrane material is obtained on the collector.

[0059] (2) Alkali treatment: prepare 0.1 M sodium hydroxide aqueous solution, place the PCL nanofiber membrane material in the solution, react at 0° C. for 20 minutes, and rinse with a large amount of deionized water.

[0060] (3) Typing of gelatin macromolecules: the PCL nanofiber membrane material obtained in step (2) is put into a concentration of 200 mM dehydrating agent carbodiimide, and after reacting at room temperature for 16 hours, soak and rinse with a large amount of deionized water , and then soaked in a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com