Emergent adsorption material prepared through utilizing waste PET (polyethylene terephthalate) fibers and preparation method thereof

A technology of adsorption materials and fibers, which is applied in the field of emergency adsorption materials prepared by using waste PET fibers and its preparation, can solve the problems of low adsorption capacity, cumbersome preparation process, and difficult source of matrix, etc., achieve high adsorption capacity, simple synthesis process steps, The effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

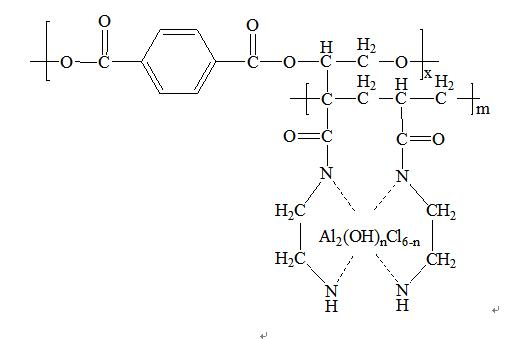

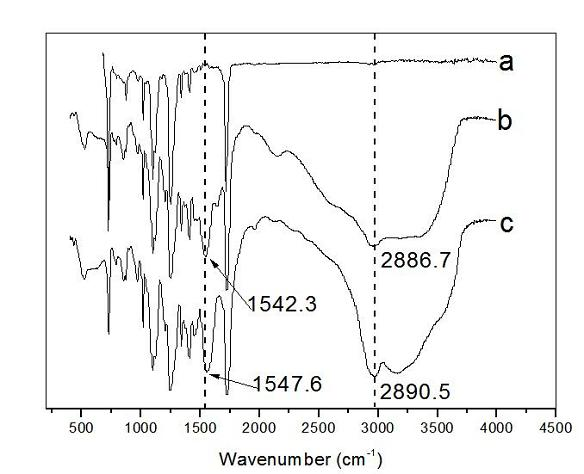

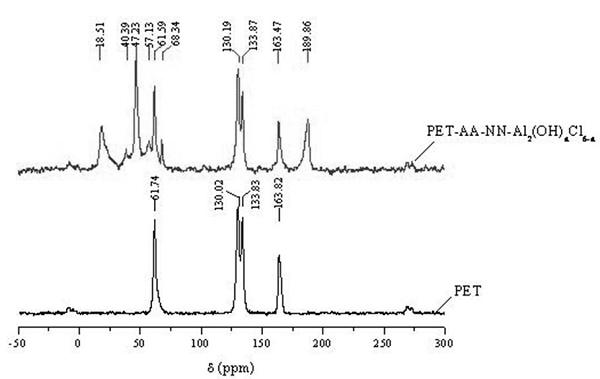

[0036] Such as Figure 7 The synthesis process of an emergency adsorption material prepared by using waste PET fibers is as follows: use 5 g of waste PET fibers and add 250 grams of ethanol to extract in a Soxhlet extractor for 8 hours, place it in a 3-necked bottle after drying, add 250 Grams of DMF swell for 8 hours (40°C). Mix and stir 100 grams of acrylic acid and 200 grams of ethylenediamine (120r / min), stir and react at 40°C for 12 hours, then add 600 grams of DMF and 300 grams of polyoxyethylene sorbitan oleate (Tween-80) to prepare into an emulsion. Pour the emulsion into a 3-neck bottle filled with PET, add 1 g of benzoyl peroxide, heat in a water bath at 95°C, and stir the reaction at a speed of 120r / min for 12 hours. separated, washed with acetone, dried, and weighed

[0037] The grafting rate of PET-AA-NN was 470%. Soak PET-AA-NN in 1000 ml of 5% aluminum chloride solution, react for 12 hours at 40°C with a stirring rate of 120r / min, and take it out to obtain P...

Embodiment 2

[0042] Use 5g of waste PET (polyethylene terephthalate) fibers to add 250 grams of acetone to extract in a Soxhlet extractor for 8 hours, put it in a 3-necked bottle after drying, add 250 grams of dichloroethane to swell 8 hours (swelling temperature is 30 degrees Celsius). Mix 100 grams of acrylic acid with 400 grams of ethylenediamine, stir (120r / min) at 40°C for 12 hours, then add 1000 grams of dichloroethane and 500 grams of polyoxyethylene oleate (OE-6) to form an emulsion . Pour the emulsion into a 3-neck bottle filled with PET, add 1g of diacyl peroxide, heat in a water bath at 95°C, and stir the reaction at a speed of 120r / min for 12 hours, and perform solid-night separation of the obtained PET-AA-NN , washed with acetone, dried in the air, and the grafting rate of the PET-AA-NN obtained by weighing was 520%. Soak PET-AA-NN in 1000 ml of 20% aluminum chloride solution, react for 12 hours at 40°C with a stirring rate of 120r / min, and take it out to obtain PET-AA-NN-Al...

Embodiment 3

[0047] Use 5g of waste PET fiber and add 250g of petroleum ether to extract it in a Soxhlet extractor for 8 hours, put it in a 3-neck bottle after drying, add 250g of toluene to swell for 8 hours, and the swelling temperature is 40 degrees Celsius. After mixing 100 grams of acrylic acid and 300 grams of ethylenediamine, stir (120 r / min) at 40 ° C for 12 hours, then add 800 grams of toluene and 400 grams of diglycerol polypropylene glycol ether to form an emulsion. Pour the emulsion into a 3-neck bottle filled with PET, add 1g of azobisethylbutyronitrile, heat in a water bath at 95°C, and stir the reaction at a speed of 120r / min for 12 hours, and carry out solid- Separate at night, wash with acetone, dry in the air, and weigh the graft rate of the obtained PET-AA-NN to be 490%. Soak PET-AA-NN in 1000 ml of 10% aluminum chloride solution, react for 12 hours at 40°C with a stirring rate of 120r / min, and take it out to obtain PET-AA-NN-Al 3+ Fiber, PET-AA-NN-Al 3+ Soak the fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com