Method for preparing graphene from three-dimensional porous carbon material and three-dimensional porous graphene

A three-dimensional porous and graphene technology, applied in the field of three-dimensional porous carbon material grapheneization and three-dimensional porous graphene, can solve the problems affecting the application of three-dimensional graphene, the large pore size of graphene, and the inability to maintain the three-dimensional skeleton, and achieve stable pores, The effect of high thermal conductivity and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] a) Preparation of three-dimensional macroporous carbon powder material: SiO with a particle size of 100-800nm 2 The microsphere colloid is assembled into a template by deposition, and the template gap is filled with a solution with a mass concentration of 1%-15% organic matter. After carbonization at a high temperature of 700-1000°C, SiO is removed with a 10%-30% HF solution 2 template to obtain a three-dimensional ordered hexagonal macroporous carbon material. The pore size distribution is 80-750nm, and the large pores are connected by small windows to form an internal three-dimensional cross-linked macropore network;

[0036] b) Three-dimensional macroporous carbon powder material is transformed into three-dimensional porous graphene:

[0037] Place the three-dimensional macroporous carbon powder material obtained in a) or other commercial three-dimensional carbon materials in a tube-type atmosphere furnace, and after vacuuming to below 20Pa, the flow rate of 5-40 sc...

Embodiment 1

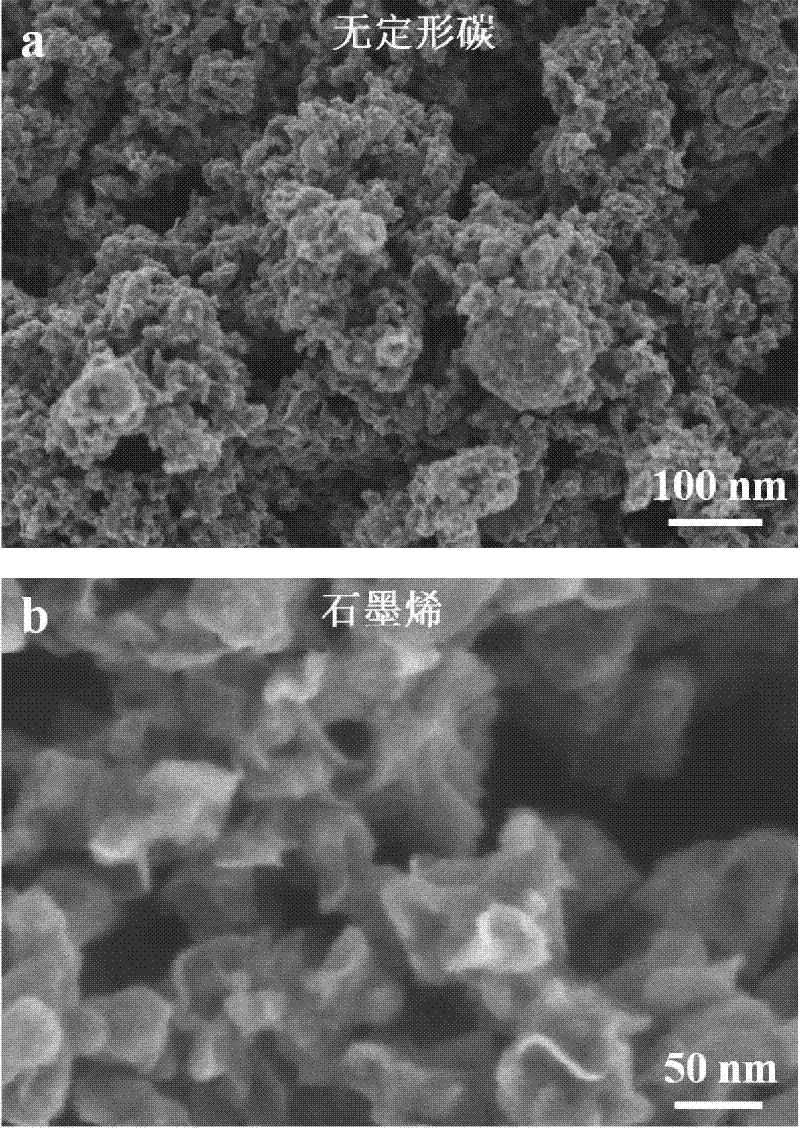

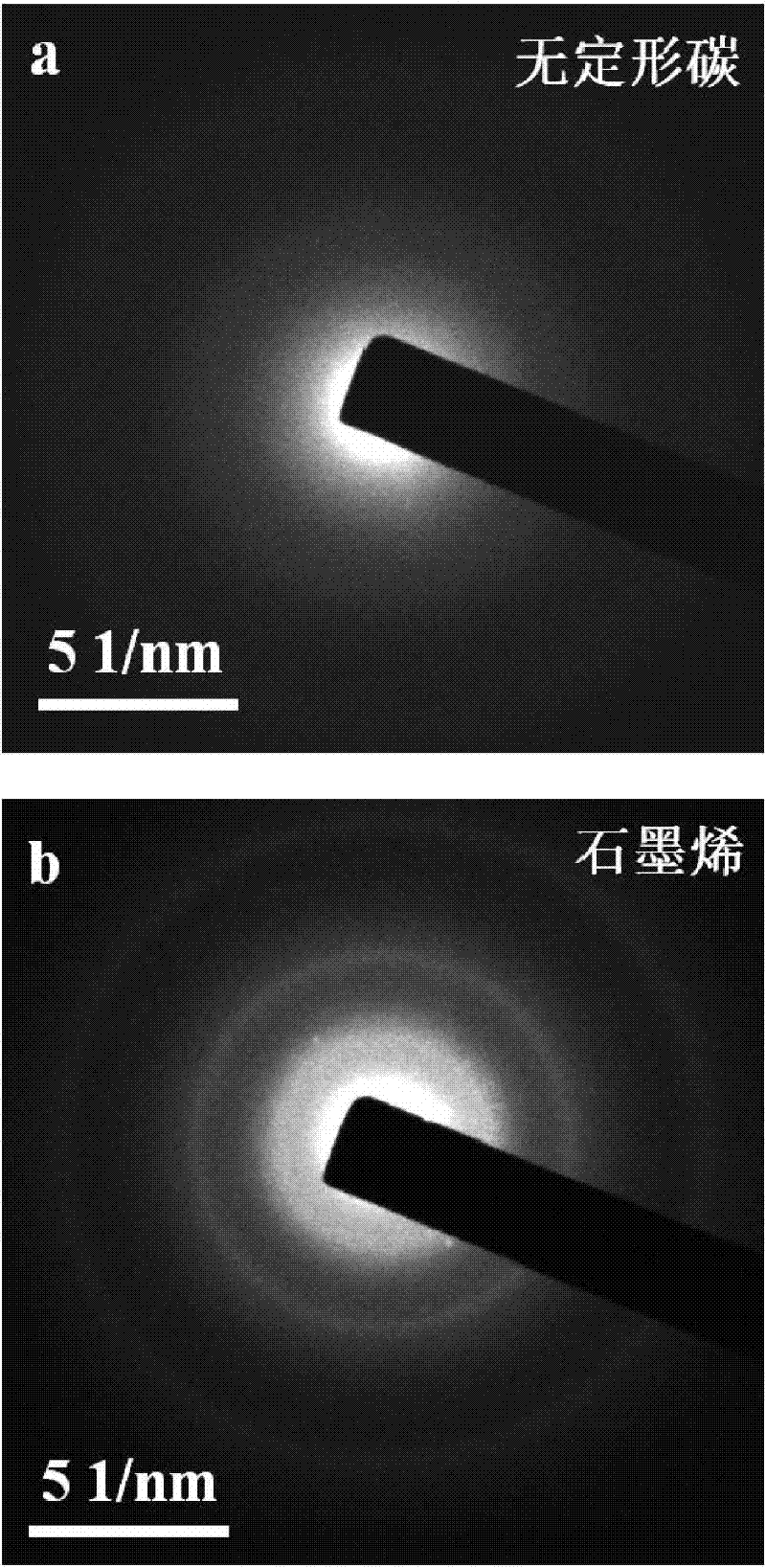

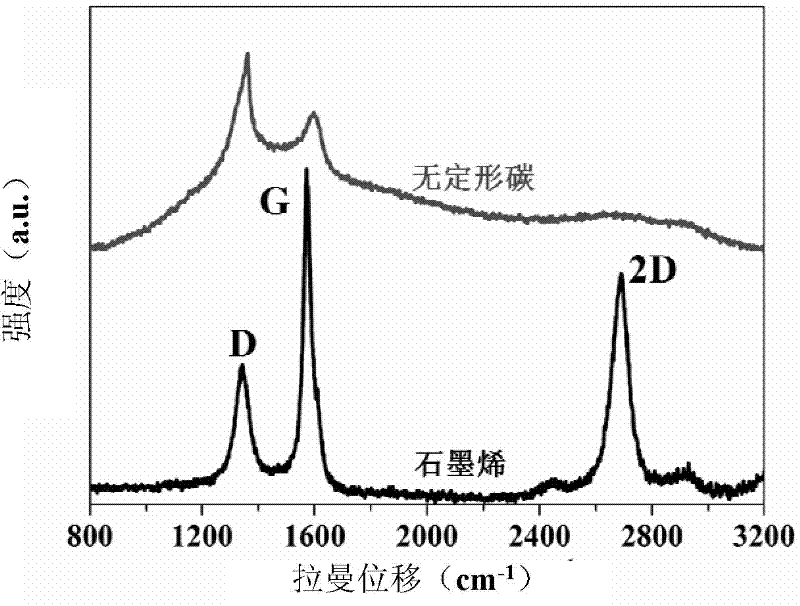

[0050] 1) Preparation of three-dimensional macroporous carbon material: use analytically pure ethyl orthosilicate, absolute ethanol, ammonia water and deionized water with a mass fraction of 25%, according to the volume ratio of 1:10:0.2:0.1, at room temperature Down mixing and continuous stirring for 2 hours; adding a volume ratio of 20% of a mass concentration of 10% PVA ethanol solution, stirring for 2 hours; then aged for 5 days, and finally refluxed for 12 hours to prepare organic matter / SiO 2 Precursor Sol. The white powder after the sol is suction filtered and dried; the above white powder is placed in a tubular atmosphere furnace, and the temperature is raised to 900°C under anaerobic conditions for carbonization to obtain three-dimensional amorphous carbon. The above black powder was placed in HF solution with a mass fraction of 30%, and stirred for 1 hour to fully remove the silica template. After filtering and drying, the three-dimensional macroporous amorphous car...

Embodiment 2

[0059] 1) Preparation of three-dimensional macroporous carbon thin film material

[0060] Use analytically pure tetraethyl orthosilicate, absolute ethanol, ammonia water and deionized water with a mass fraction of 25%, according to the volume ratio of 1:10:0.2:0.1, mix and continuously stir at room temperature for 2 hours; add volume The ethanol solution of 10% PVA with a mass concentration of 20% was stirred for 2 hours; then aged for 5 days, and finally refluxed for 12 hours to prepare organic matter / SiO 2 Precursor Sol. Then use 25×75mm 2 Quartz sheet, SiO prepared by pulling coating technology at a speed of 10mm / min 2 / PVA transparent film layer, the thickness is 50nm;

[0061] 2) Grapheneization of three-dimensional macroporous carbon thin film materials

[0062] The above-mentioned transparent film is placed in a tube-type atmosphere furnace, and after vacuuming to 10Pa, the flow rate of 20sccm H 2 . After the atmosphere furnace is heated up to the target temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com