Method for preparing graphene from limestone

A graphene and limestone technology, applied in the field of graphene preparation, can solve the problems of complex process, highly toxic chemicals and high cost, and achieve the effects of simple preparation process, wide sources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: A method for preparing graphene using limestone as a raw material, including the following steps:

[0015] 1) Mix and grind powders of calcium carbonate and magnesium metal powder with a mass ratio greater than 100:48, and the grinding time is 30 minutes;

[0016] 2) Put the powder of step 1) into a high-temperature furnace, heat up to 1000℃ within 6 hours under the protection of argon gas 60ml / min, react at 1000℃ for 40 minutes, and then cool to room temperature under the protection of argon gas , The gray powder is obtained;

[0017] 3) Reacting the obtained gray powder with a hydrochloric acid solution with a hydrogen ion concentration of 3 mol / L for 20 minutes, and then washing with distilled water to neutrality, to obtain high-purity graphene. Then it is washed with distilled water to neutrality to obtain high-purity graphene.

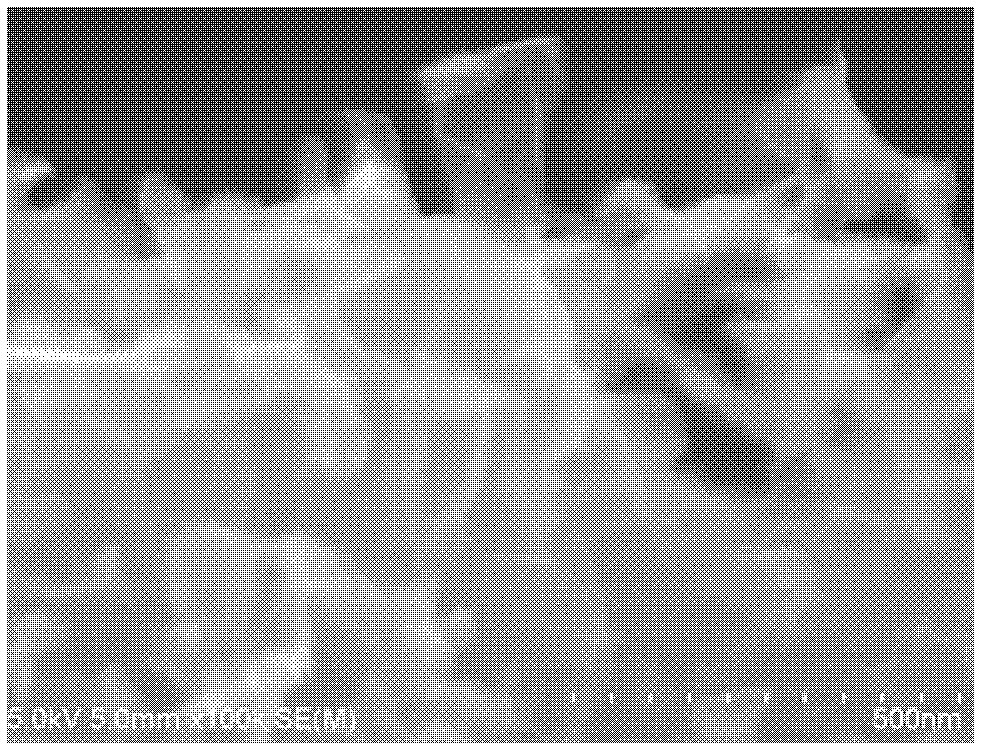

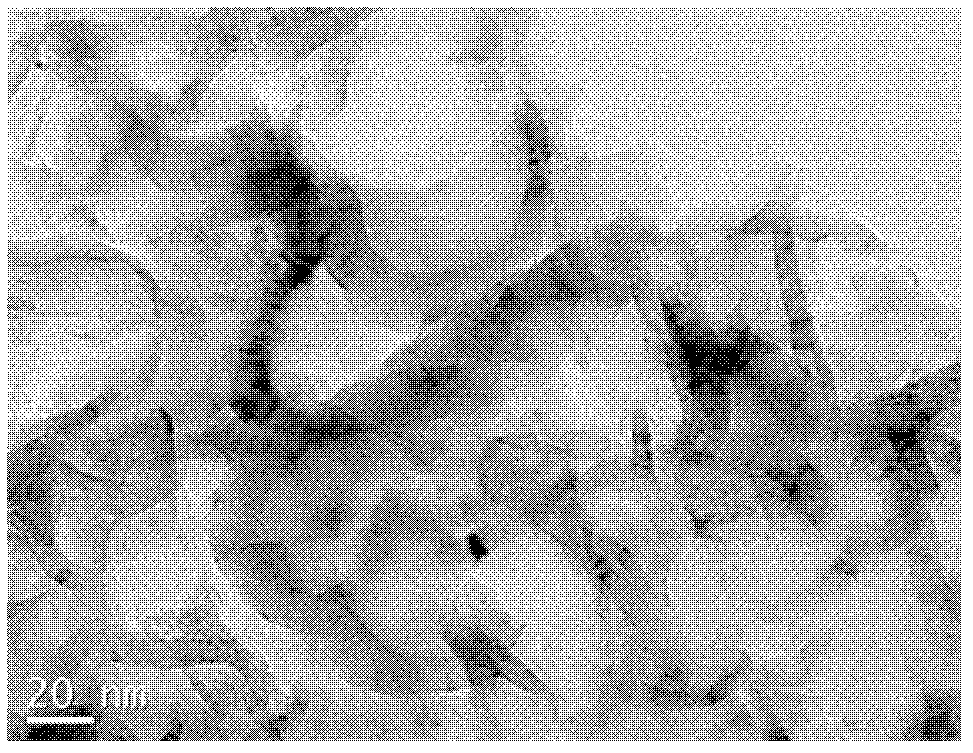

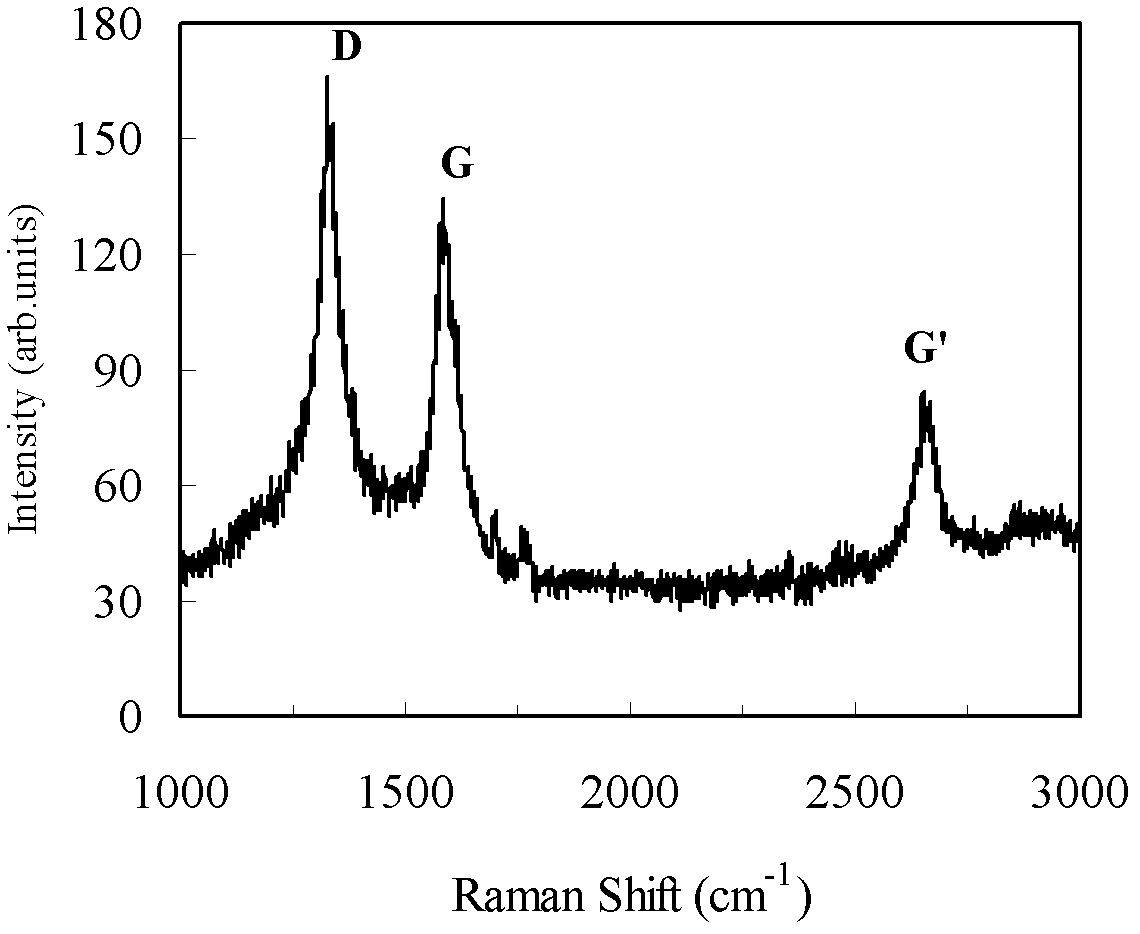

[0018] The resulting graphene SEM such as figure 1 As shown, TEM is like figure 2 As shown, the Raman spectrum is as image 3 Shown....

Embodiment 2

[0023] Embodiment 2: A method for preparing graphene using limestone as a raw material, including the following steps:

[0024] 1) Mix and grind powders of calcium carbonate and metal magnesium powder with a mass ratio greater than 100:52, and the grinding time is 40 minutes;

[0025] 2) Put the powder of step 1) into a high temperature furnace, heat up to 800℃ within 5 hours under the protection of argon gas 62ml / min, react at 800℃ for 60 minutes, and then cool to room temperature under the protection of argon gas , The gray powder is obtained;

[0026] 3) Reacting the obtained gray powder with a sulfuric acid solution with a hydrogen ion concentration of 2 mol / L for 40 minutes, and then washing with distilled water to neutrality, to obtain high-purity graphene.

Embodiment 3

[0027] Embodiment 3: A method for preparing graphene using limestone as a raw material, including the following steps:

[0028] 1) Mix and grind powders of calcium carbonate and magnesium metal powder with a mass ratio greater than 100:55, and the grinding time is 30 minutes;

[0029] 2) Put the powder of step 1) into a high temperature furnace, heat up to 1100°C within 4 hours under the protection of argon gas 65ml / min, react at 1100°C for 30 minutes, and then cool to room temperature under the protection of argon gas , The gray powder is obtained;

[0030] 3) Reacting the obtained gray powder with a nitric acid solution with a hydrogen ion concentration of 4 mol / L for 30 minutes, and then washing with distilled water to neutrality, to obtain high-purity graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com