Method for preparing ketal by catalysis of ionic liquid and dehydration of acid-resistant molecular sieve membrane

A molecular sieve membrane, ionic liquid technology, applied in chemical instruments and methods, preparation of organic compounds, formation/introduction of ether groups/acetal groups/ketal groups, etc. and other problems, to achieve the effect of high degree of greening, lower production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

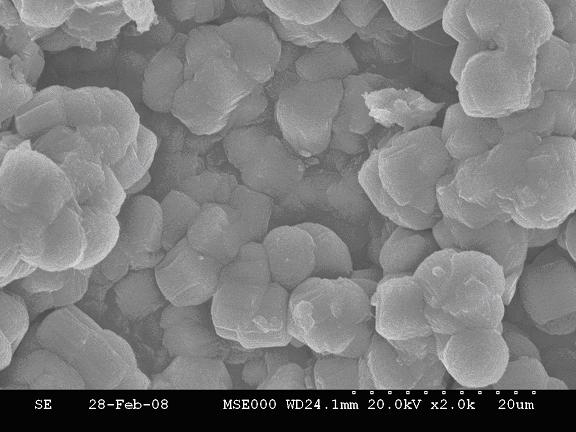

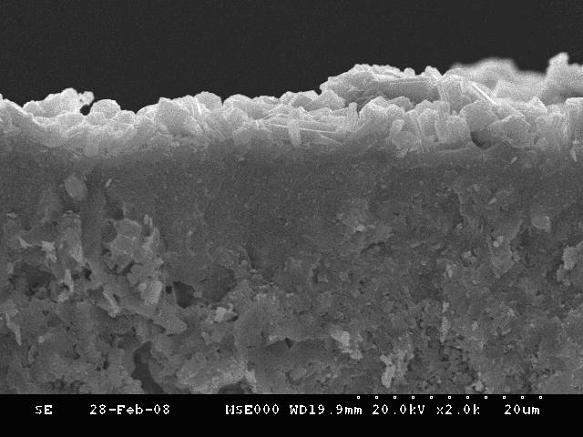

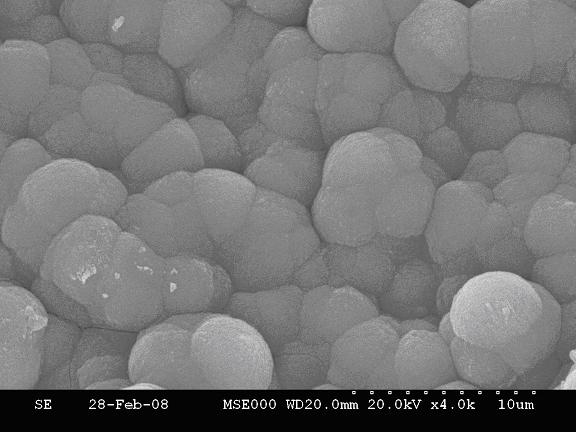

Image

Examples

Embodiment 1

[0028] 0.5 mol acetone, 1 mol methanol, 0.2 g [Pr 3 NH]][HSO 4] The acidic ionic liquid is mixed and added to the reaction tank 1, and the stirring reaction is started at 0°C; the metering pump 2 is started, and the reaction mixture is pumped into the preheater 3, and after the feed liquid is heated to 70°C, it enters the acid-resistant molecular sieve membrane module 5 for further Permeation separation, the permeated steam enters the cold trap 7 driven by negative pressure, and is quickly condensed and collected by liquid nitrogen, and the retained liquid is cooled by the condenser 6, and then returns to the reaction tank 1 to continue to participate in the reaction; after 2 hours of continuous operation of the membrane pervaporation device , the reaction ends, and the reaction mixture in the reaction tank 1 is statically separated. Since the product ketal is insoluble in [Pr 3 NH][HSO 4 ] in acidic ionic liquids, while acetone and methanol are soluble in [Pr 3 NH][HSO 4...

Embodiment 2

[0030] 0.5 mol acetone, 1 mol ethanol, 0.3 g [Et 3 NH]][HSO 4 ] The acidic ionic liquid is mixed and added to the reaction tank 1, and the stirring reaction is started at 0°C; the metering pump 2 is started, and the reaction mixture is pumped into the preheater 3, and after the feed liquid is heated to 70°C, it enters the acid-resistant molecular sieve membrane module 5 for further Permeation separation, the permeated steam enters the cold trap 7 driven by negative pressure, and is quickly condensed and collected by liquid nitrogen, and the retentate is cooled by the condenser 6, and then returned to the reaction tank 1 to continue to participate in the reaction; after the membrane pervaporation device has been continuously operated for 1.5 hours , the reaction ends, and the reaction mixture in the reaction tank 1 is statically separated. Since the product ketal is insoluble in [Et 3 NH][HSO 4 ] in acidic ionic liquids, while acetone and ethanol can be dissolved in [Et 3 N...

Embodiment 3

[0032] 0.5 mol acetone, 1 mol propanol, 0.5 g [Bu 3 NH][HSO 4 ] The acidic ionic liquid is mixed and added to the reaction tank 1, and the stirring reaction is started at 0°C; the metering pump 2 is started, and the reaction mixture is pumped into the preheater 3, and after the feed liquid is heated to 70°C, it enters the acid-resistant molecular sieve membrane module 5 for further Permeation separation, the permeated steam enters the cold trap 7 driven by negative pressure, and is quickly condensed and collected by liquid nitrogen, and the retentate is cooled by the condenser 6, and then returned to the reaction tank 1 to continue to participate in the reaction; after the membrane pervaporation device has been continuously operated for 1.5 hours , the reaction ends, and the reaction mixture in the reaction tank 1 is statically separated. Since the product ketal is insoluble in [Bu 3 NH][HSO 4 ] in acidic ionic liquids, while acetone and propanol can be dissolved in [Bu 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com