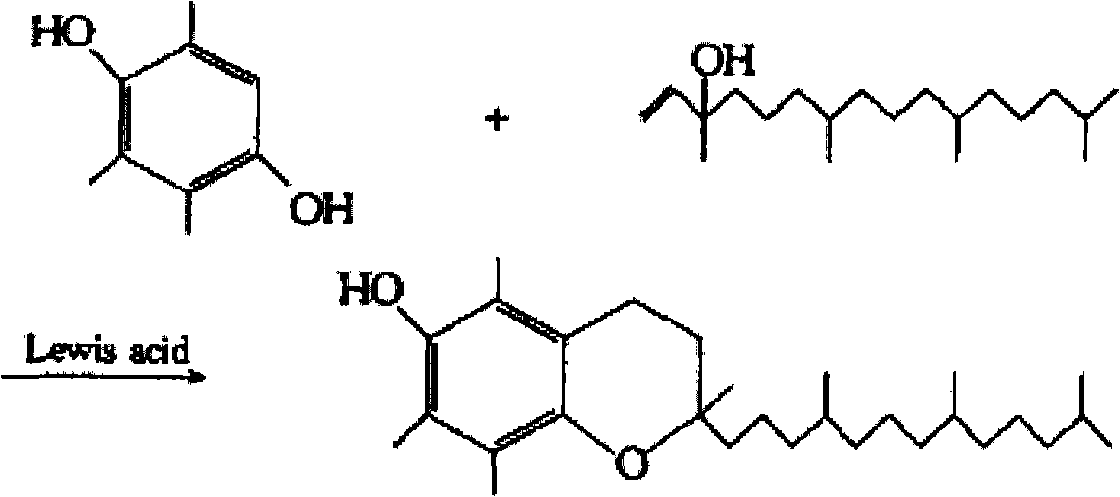

Preparation method of vitamin E

A vitamin and organic solvent technology, applied in the field of vitamin E preparation, can solve problems such as poor product purity and low yield, and achieve the effects of short reaction time, easy availability of raw materials, and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] At room temperature, put 180g of 2,3,5-trimethylhydroquinone, 180g of zinc chloride, 420mL of toluene, and 20g of 36% hydrochloric acid into a 1L four-neck flask under nitrogen protection, and stir for 20 minutes. The water bath was heated to 40°C, and the nitrogen flow was stopped. Then dropwise add 362g of isophytic alcohol, and control the dropwise addition in about 2 hours. After the isophytic alcohol is added dropwise, add 1.9g of zinc powder under the protection of nitrogen gas, then stop the nitrogen gas flow, maintain the heating temperature at about 40°C, keep warm for 2 hours, then pass nitrogen gas protection to cool, and filter. Add 120mL of water, stir, pour into a separatory funnel and let stand for 20 minutes to separate layers, and remove the water layer. Add 120mL of 1% sodium bicarbonate solution by mass, stir, pour into a separatory funnel and let stand for 20 minutes to separate layers, and remove the water layer. Then add 120mL of pure water, stir...

Embodiment 2

[0025] At room temperature, 180 g of trimethylhydroquinone, 180 g of zinc chloride, 300 mL of benzene, and 15 g of 35% hydrochloric acid by mass were put into a 1L four-neck flask under nitrogen protection, and stirred for 15 minutes. The water bath was heated to 55°C, and the nitrogen flow was stopped. Then dropwise add 340g isophytic alcohol, and control the dropwise addition in about 3 hours. After the isophytic alcohol is added dropwise, add 3.0g of zinc powder under the protection of nitrogen gas, then stop the nitrogen gas flow, maintain the heating temperature at about 55°C, keep warm for 3 hours, then pass nitrogen gas protection to cool, and filter. Add 150mL of water, stir, pour into a separatory funnel and let stand for 25 minutes to separate layers, and remove the water layer. Add 150mL of 1% potassium bicarbonate solution by mass, stir, pour into a separatory funnel and let stand for 25 minutes to separate layers, and remove the water layer. Then add 120mL of pu...

Embodiment 3

[0027] At room temperature, put 180g of 2,3,5-trimethylhydroquinone, 195g of zinc chloride, 480mL of toluene, and 42g of 25% hydrochloric acid into a 1L four-neck flask under nitrogen protection, and stir for 20 minutes. The water bath was heated to 35°C, and the nitrogen flow was stopped. Then dropwise add 380g of isophytic alcohol, and control the dropwise addition in about 3 hours. After the isophytic alcohol is added dropwise, add 1.0g of zinc powder under the protection of nitrogen gas, then stop the nitrogen gas flow, maintain the heating temperature at about 35°C, keep warm for 4.5 hours, and then pass nitrogen gas protection to cool and filter. Add 100mL of water, stir, pour into a separatory funnel and let stand for 20 minutes to separate layers, and remove the water layer. Add 100 mL of 1% potassium bicarbonate solution by mass, stir, pour into a separatory funnel and let stand for 30 minutes to separate layers, and remove the water layer. Then add 120mL of pure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com