Halogen-free intumescent flame-retardant polypropylene mixture and preparation method thereof

A technology of flame retardant polypropylene and intumescent flame retardant, which is applied in the field of resin flame retardant modification, can solve the problems of many polar groups, high water solubility of pentaerythritol, unsatisfactory water resistance and flame retardant efficiency, and achieve Excellent water resistance, less flame retardant dosage, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example is the preparation of a silicon-containing triazine macromolecule char-forming agent and an organic ceramic precursor.

[0020] Add 36.8g of cyanuric chloride and 50mL of acetone in a 500mL four-necked flask equipped with a reflux condenser, a thermometer, a stirrer and a constant pressure dropping funnel, and put the reaction flask into an ice-water bath and stir fully to disperse the cyanuric chloride. Evenly, control the temperature at 0-2°C, then slowly add 44.2g of γ-aminopropyltriethoxysilane and sodium hydroxide solution (8g of sodium hydroxide dissolved in 30mL of distilled water) dropwise while stirring, and control the temperature during the reaction. The temperature of the reaction system is 0-2° C., the pH value is 6, the dropwise addition time is 2 hours, and the reaction is continued for 5 hours after the dropwise addition is completed. Then the temperature was raised to 50°C, and 12g of ethylenediamine and sodium hydroxide solution (10g of so...

Embodiment 2~10 and comparative example 1~3

[0024] This group of examples is the preparation of the halogen-free intumescent flame-retardant polypropylene mixture of the present invention.

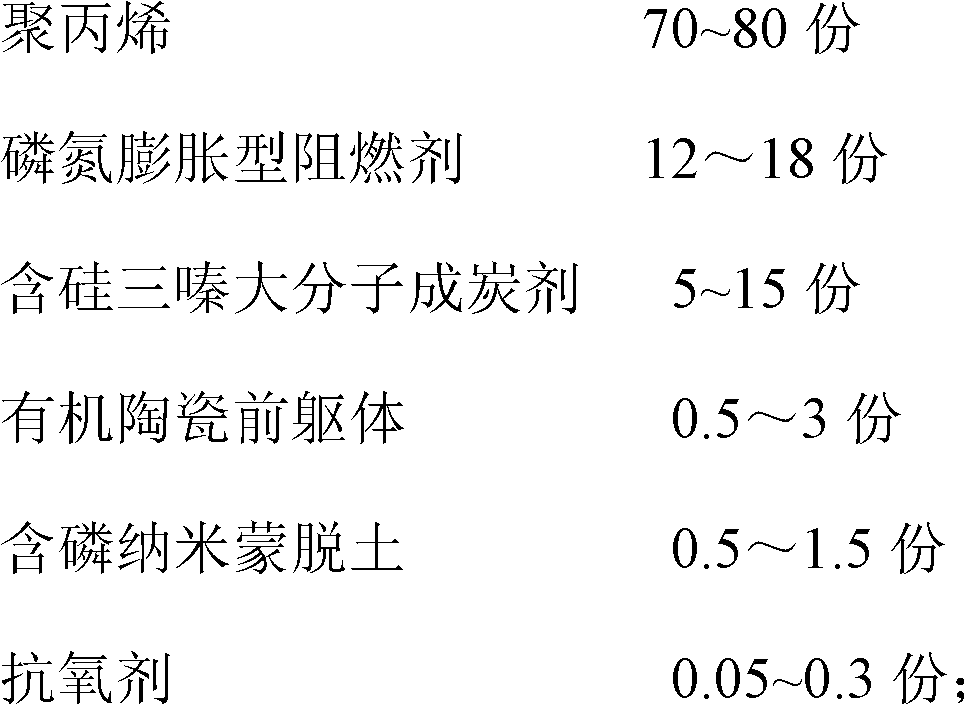

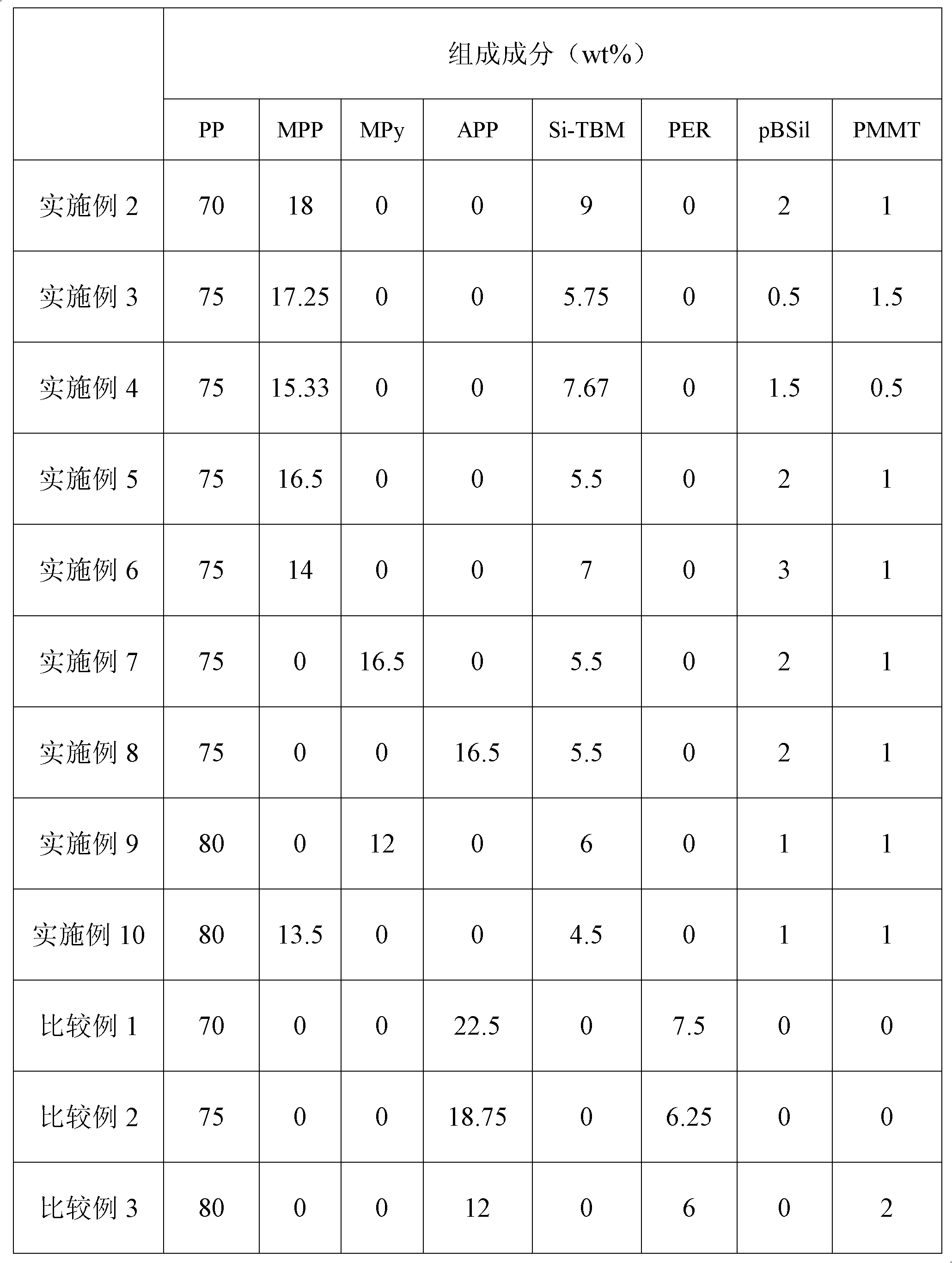

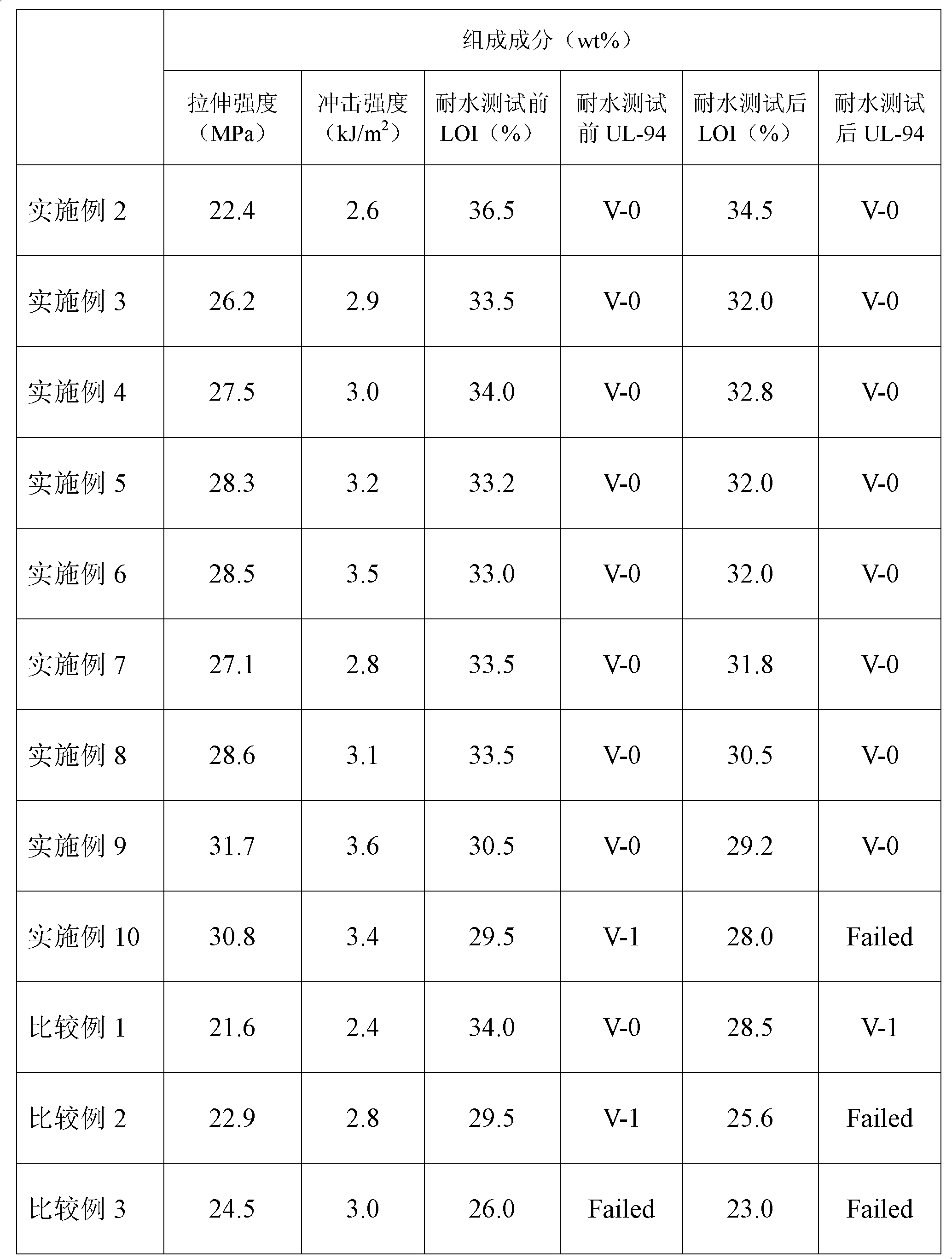

[0025] According to the formula shown in Table 1, polypropylene (PP) was first added to the open double-roller heating machine with a roll temperature of 175°C, and after it was melted and covered with rolls, antioxidant B215, phosphorus-nitrogen intumescent flame retardant, Silicon-containing triazine macromolecular char-forming agent (Si-TBM), pentaerythritol (PER), organic ceramic precursor (pBSil), and phosphorus-containing nano-montmorillonite (PMMT). After mixing for 15 minutes, the flakes are produced, and then placed on a flat vulcanizer After hot pressing at 180°C, cold pressing at room temperature, and sheeting, a flame-retardant PP sample for testing mechanical properties and flame-retardant properties was prepared on a universal prototype machine. The test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com