Azobenzene phi-phi stacked graphene photoresponse material and preparation method thereof

A light-responsive, azobenzene-based technology, applied in photovoltaic power generation, climate sustainability, final product manufacturing, etc., can solve the problems of the preparation of azobenzene π-π stacked graphene materials, light control and its optical properties. , electrical and other performance issues, to achieve the effect of fast photoresponse performance, simple manufacturing process, and fast photoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

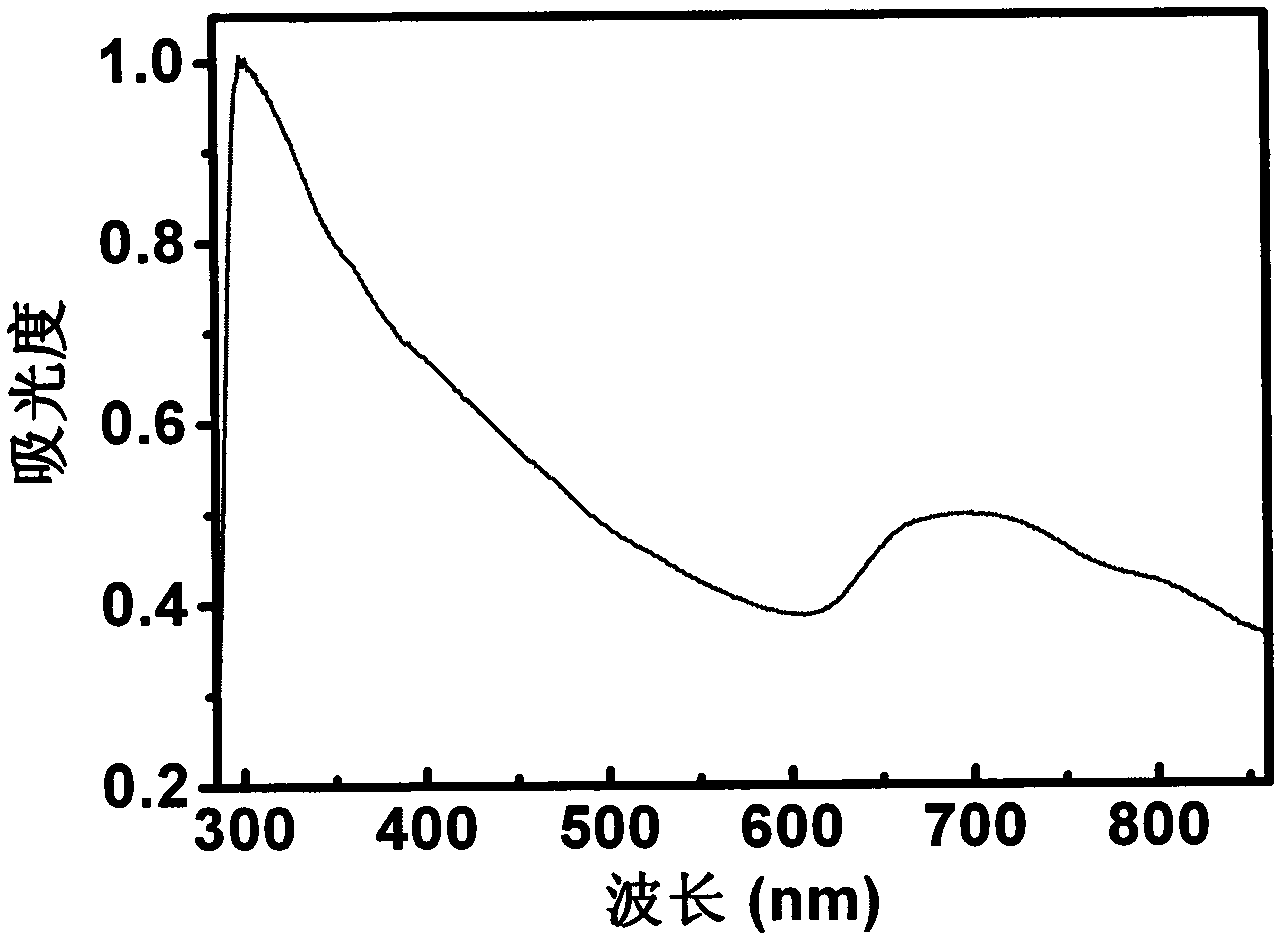

Embodiment 1

[0019] First prepare a 0.2mg / mL graphene oxide aqueous solution, take 5 pieces of indium tin oxide (ITO) glass with an area of 2×1cm, and spray the solution evenly on the indium tin oxide (ITO) glass at a temperature of 60°C. Spray 2ml of graphene oxide aqueous solution, heat treatment at 120°C for 30 minutes. Put the obtained indium tin oxide (ITO) glass with graphene oxide into a mixture of 15 mL of absolute ethanol and 15 mL of deionized water, and add 50 μL of hydrazine hydrate with a mass fraction of 80% at a temperature of 50° C. solution, reacted for 5 hours. After the reaction, the samples were taken out and dried in vacuum. Weigh 3.57mg of azobenzene 5,9,14,18,23,27,32,36-octabutoxy-2,3-naphthalocyanine copper into 5ml of acetone and disperse evenly. The indium tin oxide (ITO) glass of graphene is immersed in the prepared acetone solution containing azobenzene, taken out after 30 minutes and dried in vacuum to obtain the azobenzene π-π stacked graphene photorespon...

Embodiment 2

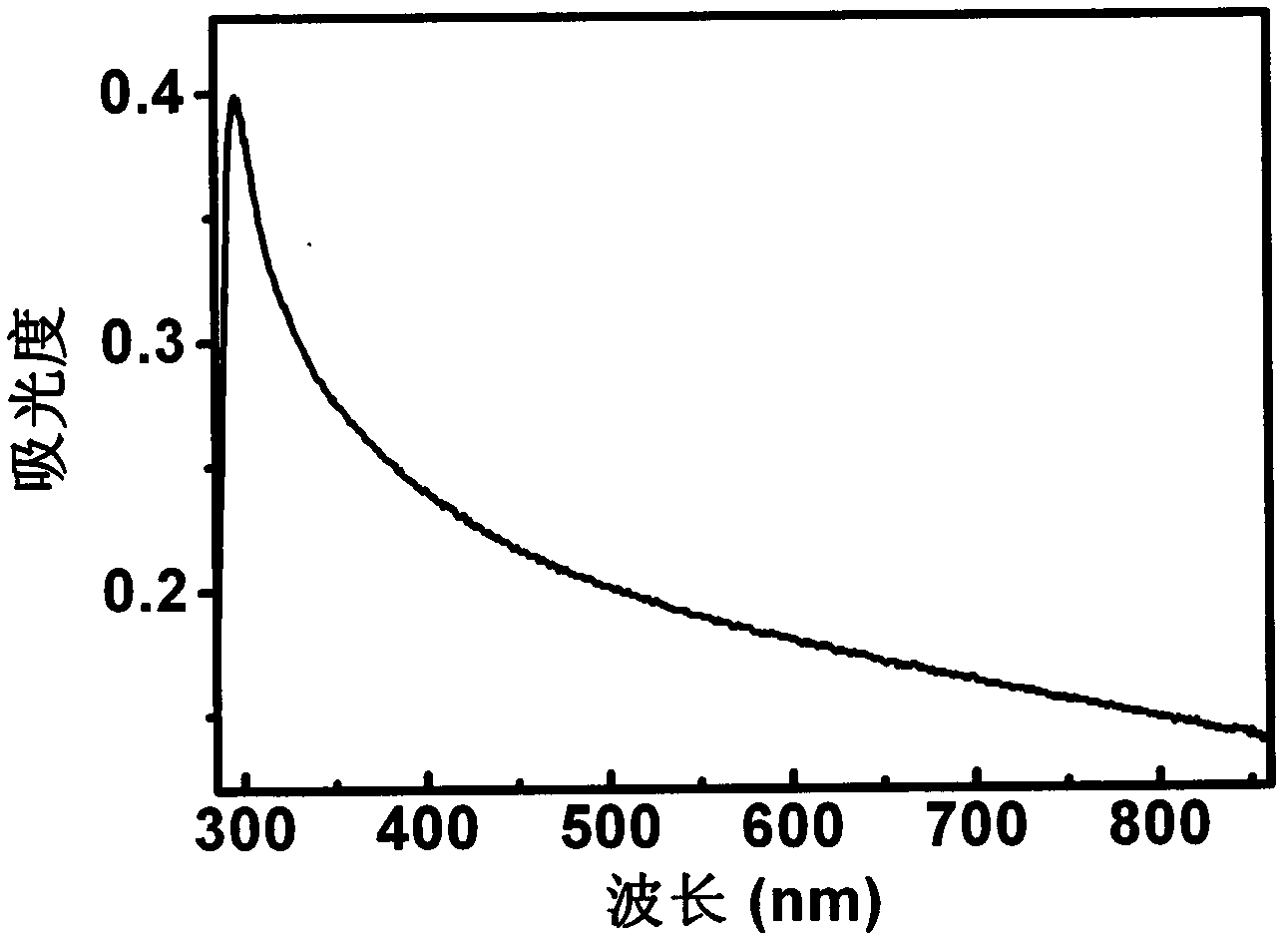

[0022] First prepare a 0.2mg / mL graphene oxide aqueous solution, take 5 pieces of indium tin oxide (ITO) glass with an area of 2×1cm, and spray the solution evenly on the indium tin oxide (ITO) glass at a temperature of 60°C. Spray 2ml of graphene oxide aqueous solution, heat treatment at 120°C for 30 minutes. Put the obtained indium tin oxide (ITO) glass with graphene oxide into a mixture of 15 mL of absolute ethanol and 15 mL of deionized water, and add 50 μL of hydrazine hydrate with a mass fraction of 80% at a temperature of 50° C. solution, reacted for 5 hours. After the reaction, the samples were taken out and dried in vacuum. Weigh 3.57 mg of azobenzene and put it into 5 ml of acetone to disperse evenly, immerse the obtained sample in the prepared mixed solution, take it out after 40 minutes and dry it in vacuum to obtain a photoresponsive material.

[0023] The prepared material is used as the working electrode, and the platinum sheet is used as the counter electro...

Embodiment 3

[0025] First prepare a 0.2mg / mL graphene oxide aqueous solution, take 5 pieces of indium tin oxide (ITO) glass with an area of 2×1cm, and spray the solution evenly on the indium tin oxide (ITO) glass at a temperature of 60°C. Spray 2ml of graphene oxide aqueous solution, heat treatment at 120°C for 30 minutes. Put the obtained indium tin oxide (ITO) glass with graphene oxide into a mixture of 15 mL of absolute ethanol and 15 mL of deionized water, and add 50 μL of hydrazine hydrate with a mass fraction of 80% at a temperature of 50° C. solution, reacted for 5 hours. After the reaction, the samples were taken out and dried in vacuum. Weigh 3.57 mg of azobenzene and put it into 5 ml of acetone to disperse evenly, immerse the obtained sample in the prepared mixed solution, take it out after 50 minutes and dry it in vacuum to obtain a photoresponsive material.

[0026] The prepared material is used as the working electrode, and the platinum sheet is used as the counter electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com