Simple production technology of special AM (arbuscular mycorrhiza) fungal manure for tobacco

A production process, fungal technology, applied in the field of AM fungal fertilizer product production process, can solve the problems of short survival time of plant roots, low effectiveness of strains, and low reproduction of strains, so as to reduce plant diseases, improve quality, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 AM fungus propagation

[0020] (a) Propagation substrate preparation: premix peat soil, field soil, and river sand according to 2:2:1 (volume ratio), and use polyethylene bags (1kg / bag). The physical and chemical properties of the propagation substrate are listed in Table 1. Group VI is shown.

[0021] (b) Sterilization: Put the packed sterilization bag into the sterilization pot, keep it at 121°C for more than 6 hours, and sterilize the culture container (or flower pot) with formaldehyde for 24 hours.

[0022] (c) Inoculation: after filling about 1 / 5 of the matrix at the bottom of the culture container, start to spread the AM fungus Glomus mosei inoculum layer by layer at intervals of 1 to 5 cm matrix (the inoculation amount is 10g / kg matrix), Up to 4 / 5 of the volume of the culture container, wash hands before inoculation.

[0023] (d) Sowing: the host Sorbus dandelion seeds are sterilized and washed 3 times with distilled water. After germination in a 2...

Embodiment 2

[0026] Embodiment 2 AM fungal fertilizer production method

[0027] Material: peat soil, field soil, river sand, humus (50% (volume) of fungus chaff and 50% (volume) of cow dung); the raw material of fungus chaff is common mushroom residue, and cow dung is common cow manure after decomposing use.

[0028] (a) Sterilization: Peat soil, field soil, river sand, and humus must be sterilized by dry heat at a high temperature of 121°C for more than 6 hours after mixing.

[0029] (b) Preparation of bacterial manure: In a well-drained field, fumigate with 95% formaldehyde solution to sterilize the surface soil, then turn the field soil down 40-50 cm, add peat soil and river sand in the field (or flowerpot) (by peat soil, field soil, river sand volume ratio is 2: 2: 1 ratio), the inoculant (the inoculant is 1 / 3 of matrix volume) that step (1) is made is sprinkled in the soil, and simultaneously Sow the seeds of clover, sundanese and tobacco (the planting ratio of clover, sundanese an...

Embodiment 3

[0030] Embodiment 3 Tobacco AM fungal bacterial fertilizer using method

[0031] (a) Inoculation: the bacterial fertilizer and the special matrix of tobacco in the pseudo-planting period (every 666.7m 2 Carry out retting according to the ratio of 20kg crushed wheat straw, 10kg ring manure and 10kg topsoil) in a ratio of 1:2 (volume ratio) for mixed use.

[0032] (b) Management: According to the conventional management of tobacco, special chemical fertilizers for tobacco (produced by Suihua Longfu Fertilizer Co., Ltd.) are applied.

[0033] Table 3 Effects of AM fungal fertilizer on the yield and K content of tobacco treated with full fertilizer and half fertilizer

[0034]

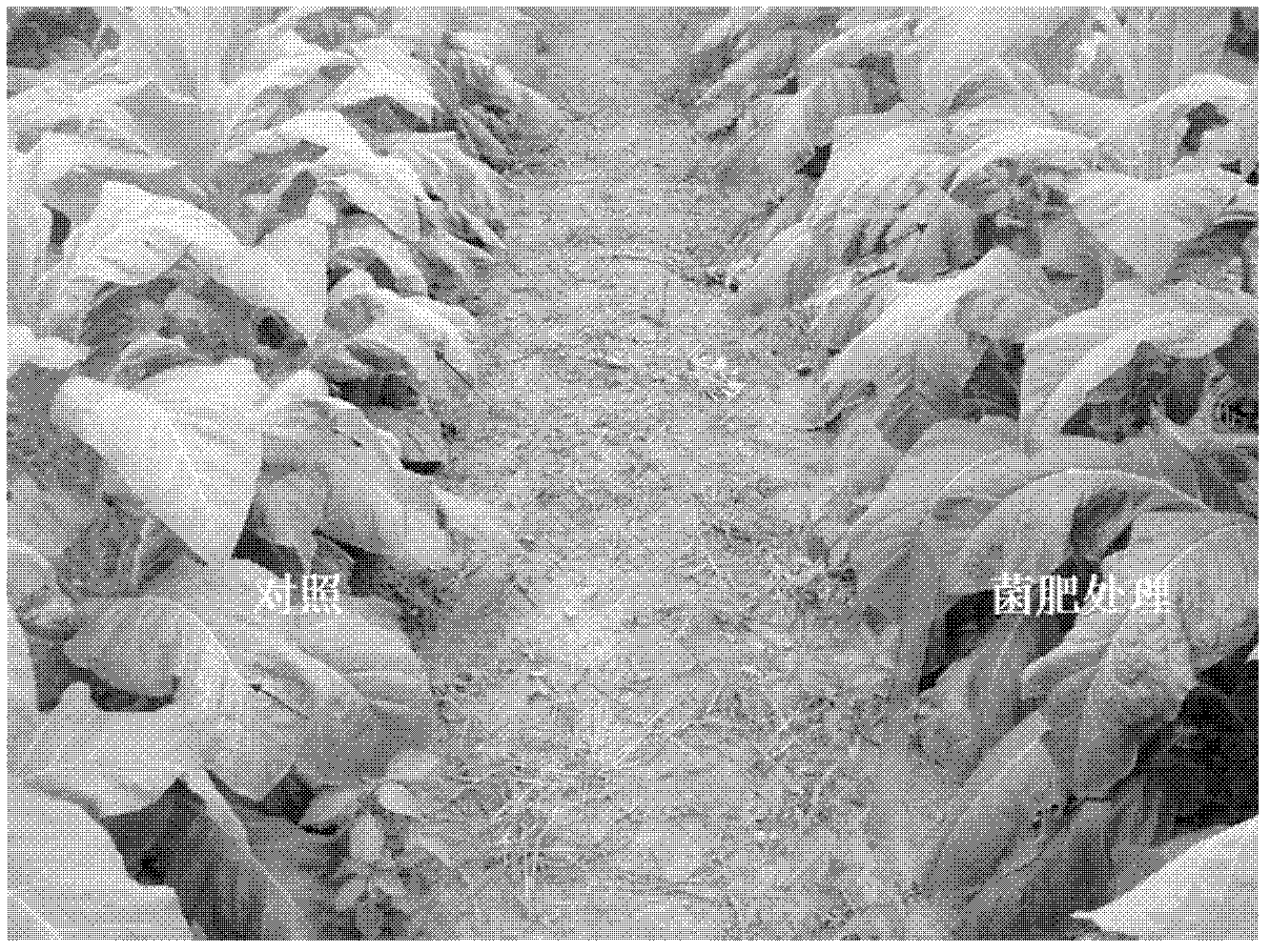

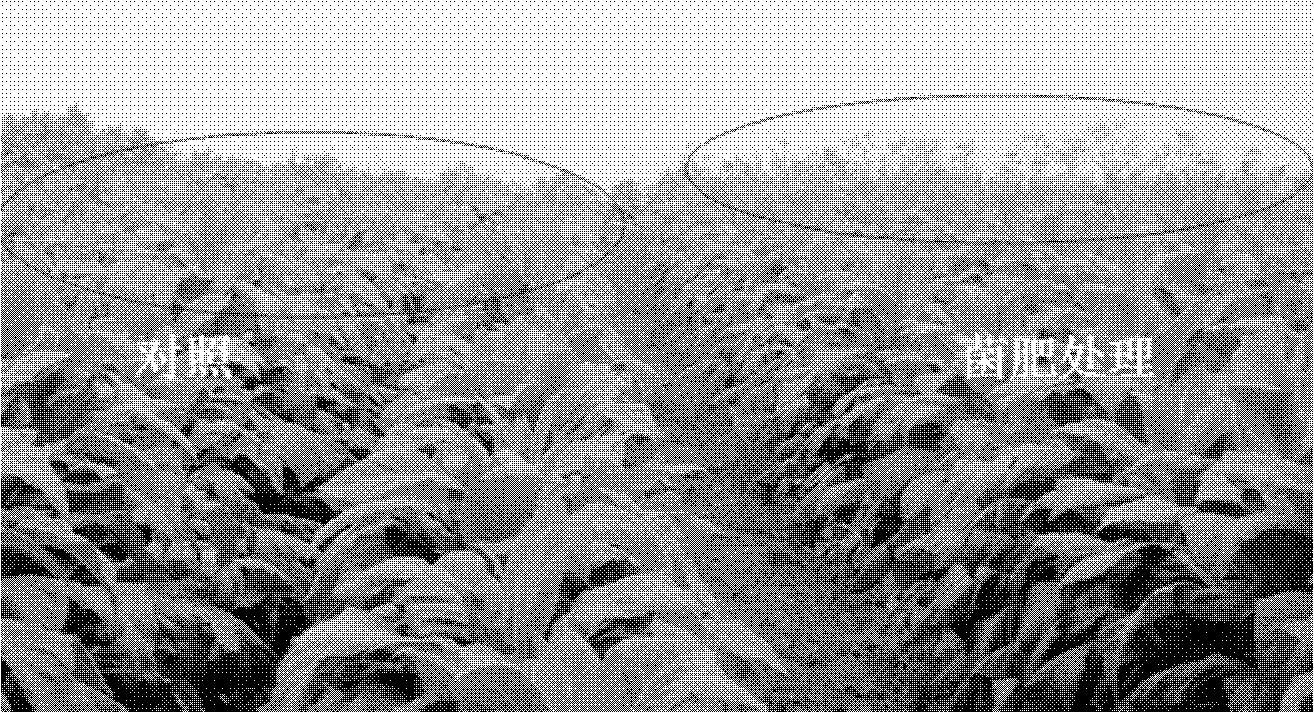

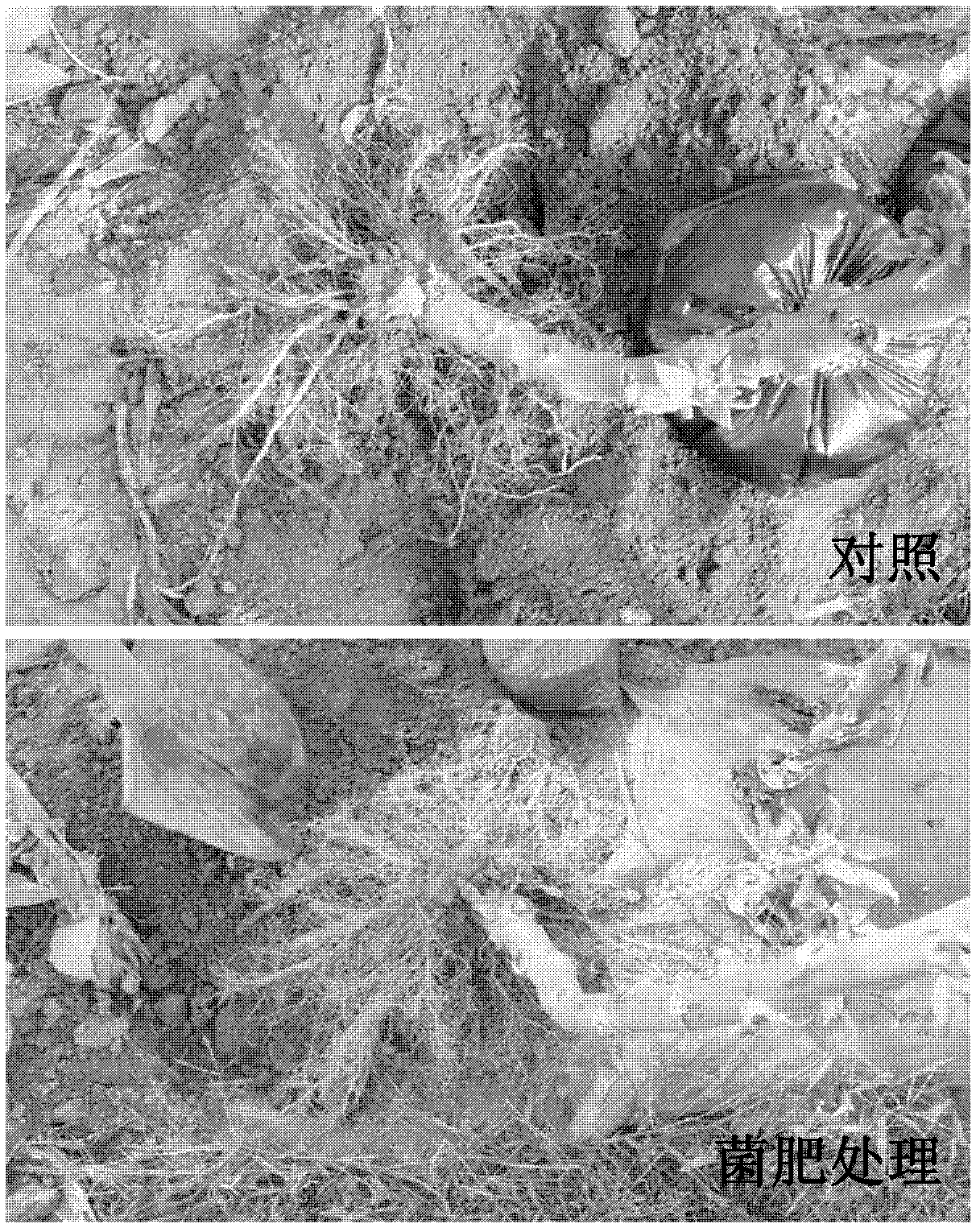

[0035] The result is as Figure 1-3 As shown in Table 3 (full fertilizer), the results show that: AM fungal fertilizer can reduce the susceptibility rate of leaves, advance the flowering time of tobacco, and increase the number of lateral roots in the root system. Under normal fertilizer and water ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com