Water-soluble multifunctional group oligomeric silsesquioxane and synthetic method of water-soluble multifunctional group oligomeric silsesquioxane

A technology of polysilsesquioxane and silsesquioxane, which is applied in the direction of silicon organic compounds and the like, can solve the problems that oligomeric silsesquioxane is difficult to functionalize, insoluble in water, etc., and achieves simple steps and simple purification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

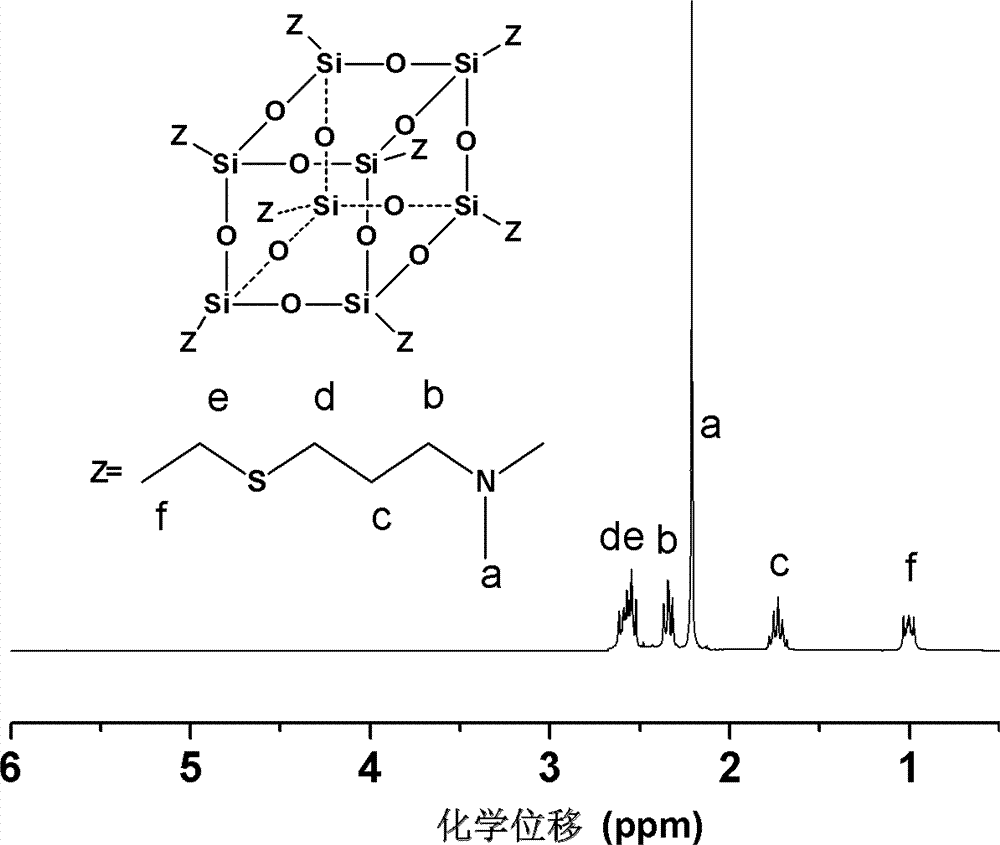

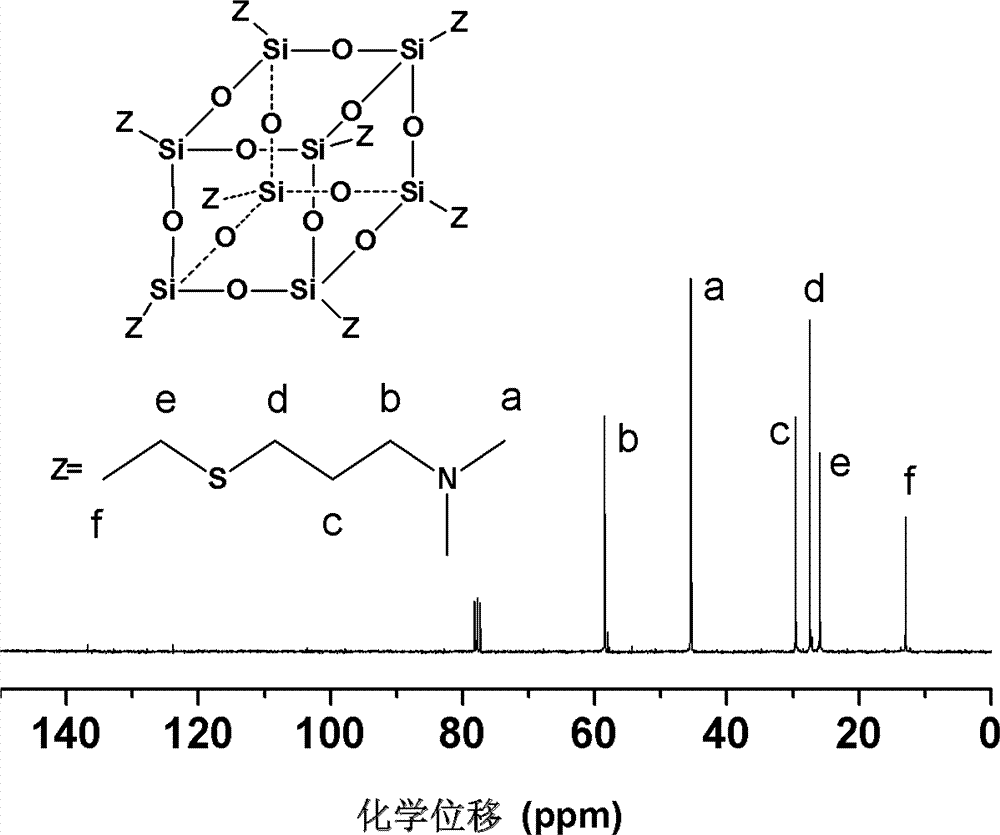

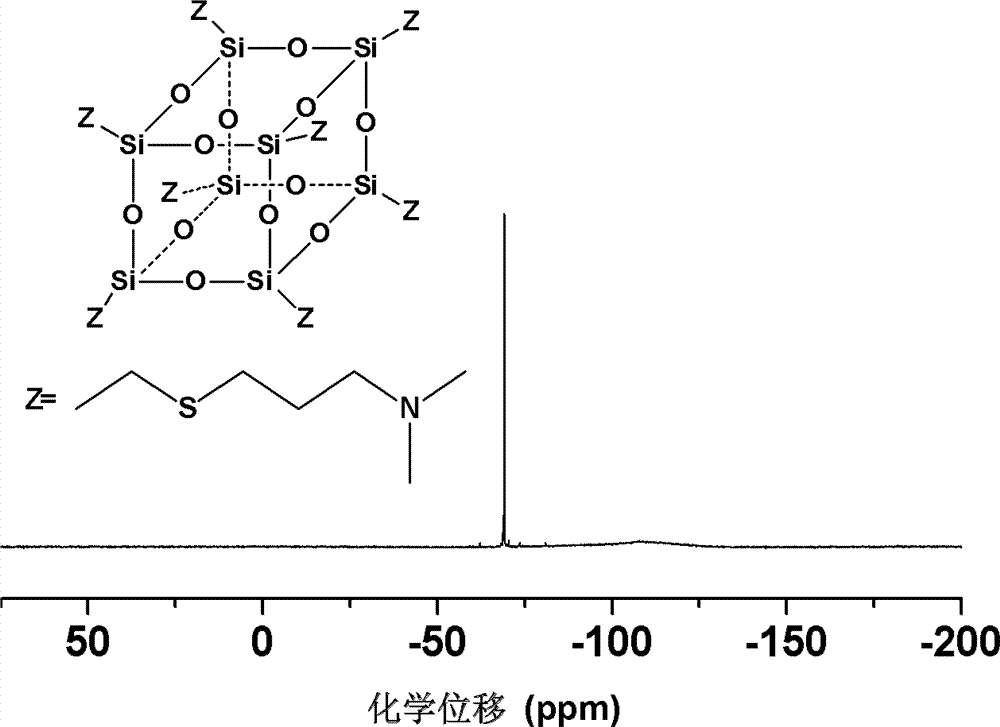

[0049] Step 1) Under the protection of nitrogen, add 1 mole of octavinyl oligosilsesquioxane, 10 moles of dry tetrahydrofuran, 20 moles of dimethylaminopropanethiol, and 0.1 mole of benzoin diethyl ether in the reactor successively. Under light irradiation reaction at ℃ for 24 hours, the intermediate was obtained after evaporation under reduced pressure to remove tetrahydrofuran and excess dimethylaminopropanethiol;

[0050] Step 2) Add 10 moles of dry N,N-dimethylformamide, then add 20 moles of propyne bromide dropwise at 0°C, react for 48 hours, add 100 moles of ether, and the precipitated precipitate is centrifuged and vacuum After drying, it is a water-soluble oligomerized silsesquioxane containing eight alkynyl groups.

Embodiment 2

[0052] Step 1) Under the protection of nitrogen, add 1 mole of octavinyl oligomerized silsesquioxane, 5 moles of dry toluene, 10 moles of dimethylaminopropanethiol, and 0.01 mole of benzoin diethyl ether in the reactor successively, at 20 Light irradiation reaction at ℃ for 2 hours, after removing toluene and dimethylaminopropanethiol by evaporation under reduced pressure, the intermediate was obtained;

[0053] Step 2) Add 3 moles of dry N,N-dimethylacetamide, then add 8.8 moles of bromopropene dropwise at -10°C, react for 0.5 hours, add 15 moles of tetrahydrofuran, and the precipitated precipitate is centrifuged and vacuum After drying, it is a water-soluble oligomerized silsesquioxane containing eight allyl groups.

Embodiment 3

[0055] Step 1) Under the protection of nitrogen, add 1 mole of octavinyl oligosilsesquioxane, 6 moles of dry benzene, 8.8 moles of dimethylaminopropanethiol, and 0.01 mole of benzoin diethyl ether in the reactor at 20 Light irradiation reaction at ℃ for 1 hour, and benzene and dimethylaminopropanethiol were evaporated under reduced pressure to obtain the intermediate;

[0056] Step 2) Add 5 moles of dry N,N-dimethylformamide, then dropwise add 8.8 moles of ethanol azide bromoacetate at -10°C, react for 0.5 hours, add 30 moles of dichloromethane, and the precipitated After centrifugation and vacuum drying, the precipitate becomes water-soluble oligomerized silsesquioxane containing eight azido groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com