Gene engineering bacterial strain generating succinic acid and method of producing succinic acid by fermentation of the gene engineering bacterial strain

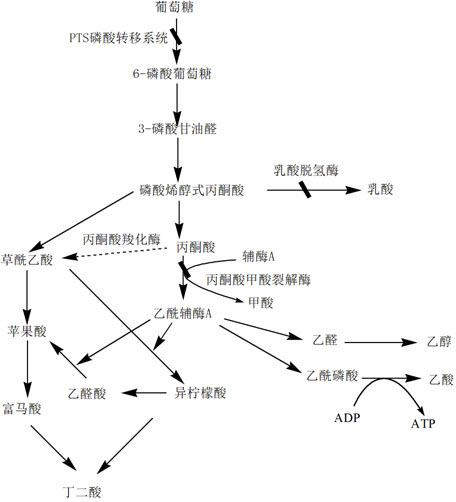

A genetically engineered bacteria, a technology for producing succinic acid, which is applied in the field of bioengineering and can solve the problems of reduced pyruvate metabolic branches, accumulation of pyruvate, and inability of strains to utilize glucose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example illustrates the use of homologous recombination technology to knock out the glucose-specific transport system in the starting strain NZN111 ptsG gene, resulting in the elimination of chloramphenicol-resistant strains.

[0043] 1. Using LB medium, cultivate Escherichia coli NZN111 to OD at 37°C under aerobic conditions 600 =0.4~0.6, prepared to be electrotransfer competent.

[0044] 2. Electrotransform plasmid pKD46 into competent Escherichia coli NZN111. The electric shock conditions were: 200 Ω, 25 μF, electric shock voltage 2.3 kV, electric shock time 4-5 ms. Immediately after the electric shock, the cells were added to pre-cooled 1 mL SOC medium, cultured at 150 r / min, 30°C for 1 h, and then spread on the LB medium plate with ampicillin (amp) to screen the positive transformant Escherichia coli NZN111 ( pKD46).

[0045] 3. Add 10 mM L-arabinose to LB medium, induce plasmid pKD46 to express λ recombinase at 30°C, and make electroporation competent. ...

Embodiment 2

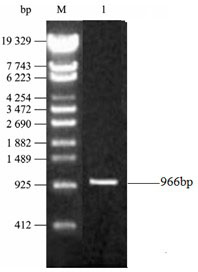

[0057] This example illustrates the construction of an expression plasmid expressing exogenous pyruvate carboxykinase to obtain a bacterial strain Escherichia coli BA103, such as Figure 4 Schematic construction shown.

[0058] 1. Construct pTrc99a- pyc Plasmids, the process of which involves:

[0059] (1) synthetic with Nco I and Pst Primers for I restriction sites,

[0060] Upstream primer: 5'- CATGCCATGGTCAGCTGATGAGAAACGTCGAGAAG -3';

[0061] Downstream primer: 5'- AAAACTGCAGGGTCATTCTCTTCAAAGCCAAAACGA-3'.

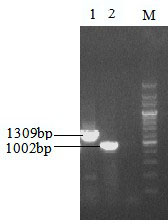

[0062] (2) to Lactococcus lactis cremoris NZ9000 genomic DNA was used as a template, and the target gene fragment was amplified by PCR. The reaction conditions were: 94°C, 5 min; (94°C for 45 s, 53°C for 45 s, 72°C for 300 s, 35 cycles); 72°C, 10 min. purified amplified pyc After the gene, the expression plasmid was used respectively with pTrc99a Nco I and Pst I double digestion, connection to obtain recombinant plasmid pTrc99a- pyc . PCR amplifie...

Embodiment 3

[0065] This example illustrates the knockout of the glucose-specific transport system in Escherichia coli NZN111 ptsG gene and introduced into plasmid pTrc99a- pyc Finally, glucose can be used efficiently, and the main product is succinic acid, without the accumulation of formic acid and lactic acid, and the generation of by-product pyruvic acid is greatly reduced.

[0066] Escherichia coli BA103 was inoculated into the aerobic stage fermentation medium with 1% (v / v) inoculum for aerobic culture, when the aerobic culture OD 600 Induced to 0.4-0.6 with 0.5 mM IPTG to OD 600 =3, transfer to the anaerobic stage fermentation medium for anaerobic fermentation for 48 hours according to 3 times the inoculum amount of the sludge.

[0067] The medium in the aerobic stage is: LB+Amp+Chl+Kna (50 μg / mL each of ampicillin, chloramphenicol, and kanamycin).

[0068] The medium for anaerobic serum bottle fermentation is: LB+glucose (20g / L)+basic magnesium carbonate 0.48g+Amp+Chl+Kna (50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com