Copper zinc tin sulfur compound thin-film solar cell and preparation method thereof

A technology of copper-zinc-tin-sulfur compound, which is applied in the field of new energy sources of optoelectronic materials, can solve the problems that restrict the large-scale industrialization of CIGS thin-film solar cells, toxicity, and poor content ratio, so as to save preparation costs, simplify process steps, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

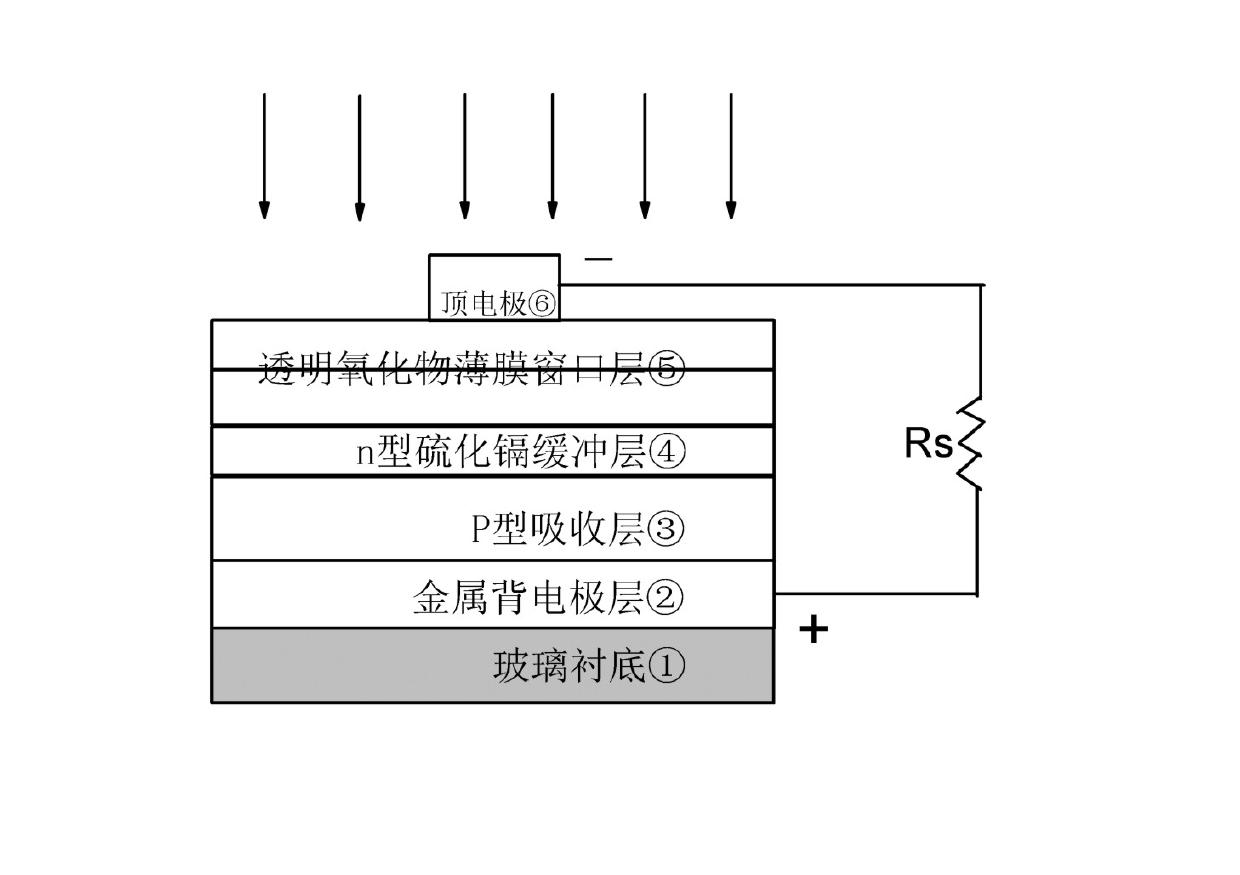

[0026] refer to figure 1 , the solar cell of the present invention comprises: a glass substrate ①, a metal back electrode layer ②, a P-type absorber layer ③, an n-type cadmium sulfide buffer layer ④, a transparent oxide film window layer ⑤ and a TCO top electrode ⑥, wherein: the The p-type absorbing layer ③ is a copper-zinc-tin-sulfur quaternary compound film deposited by pulsed laser, and its film thickness is 1000-2000 nanometers.

[0027] Solar cell preparation process of the present invention is as follows:

[0028] (1), the preparation of the target, the high-purity Cu 2 S, ZnS, SnS 2 The powder is mixed according to 1:1:1, ball milled in alcohol solution for 8 hours, then dried and put into a mold, pressed into a circular target (25mm in diameter, 4mm in thickness), and put into a tube furnace with argon gas , sintered at 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com