Preparation method of mesoporous A-R mixed crystal titanium oxide with controllable rutile content

An A-R, titanium oxide technology, applied in the direction of titanium dioxide, hydrocarbon production from carbon oxides, chemical instruments and methods, etc., can solve the problems of long preparation cycle, shortened reaction time, uneven mass transfer, etc., and achieve simple and easy preparation conditions and processes Controlling, stable loading of active components, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

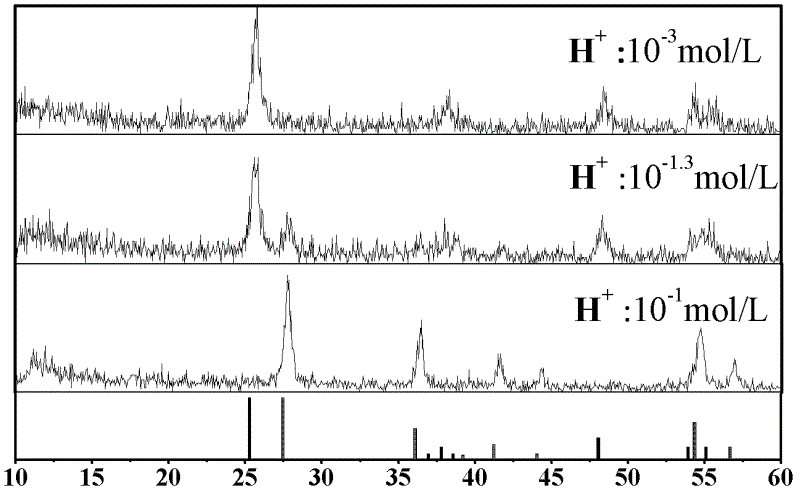

[0030] Anatase titanium oxide and sodium hydroxide are thoroughly mixed (TiO 2 : Na 2 O=0.25), calcined at 300℃ for 2h, use H + The concentration is 10 -0.5 The titanate is cleaned with mol / L nitric acid solution (that is, soaked in alkali metal titanate for 2 hours), and finally calcined in a muffle furnace at 500°C for 4 hours to obtain mesoporous titanium oxide with a maximum pore diameter of 4nm , The specific surface area is 90m 2 / g, the pore volume is 0.2cm 3 / g, the crystal form is rutile titanium oxide, in which the rutile content is 100wt%.

Embodiment 2

[0032] Anatase titanium oxide and sodium hydroxide are thoroughly mixed (TiO 2 : Na 2 O=0.25), calcined at a temperature of 300℃ for 4h, use H + The concentration is 10 -1 The titanate is cleaned with mol / L nitric acid solution (that is, soaked in alkali metal titanate for 3 hours), and finally calcined in a muffle furnace at 300°C for 4 hours to obtain mesoporous titanium oxide with the most probable pore diameter of 2nm , The specific surface area is 150m 2 / g, the pore volume is 0.5cm 3 / g, the crystal form is rutile titanium oxide, in which the rutile content is 100wt%.

Embodiment 3

[0034] Titanic acid and sodium carbonate are mixed thoroughly (TiO 2 : Na 2 O=1), calcined at 500℃ for 0.5h, use H + The concentration is 10 -1.3 The titanate is cleaned with mol / L hydrochloric acid solution (that is, soaked in alkali metal titanate for 5 hours), and finally calcined in a muffle furnace at 550°C for 2 hours to obtain mesoporous titanium oxide. The most probable pore diameter is 40nm, the specific surface area is 60m 2 / g, the pore volume is 0.18cm 3 / g, the crystal form is a mixed crystal structure of anatase and rutile, in which the content of rutile is 45% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com