Light-transparent heat insulating film, its preparation method and application

A thin film and hollow sphere technology, which is applied in building components, buildings, windows/doors, etc., can solve the problems of limited application, mechanical performance and light transmission performance, and achieve simple preparation process, no pollution of raw materials, and inhibition of inorganic-organic heterogeneity. The effect of phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

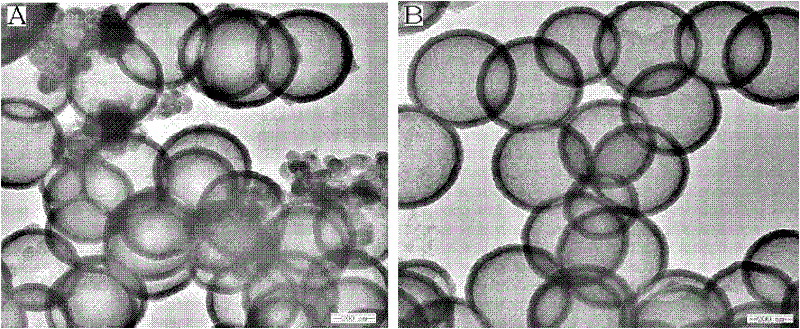

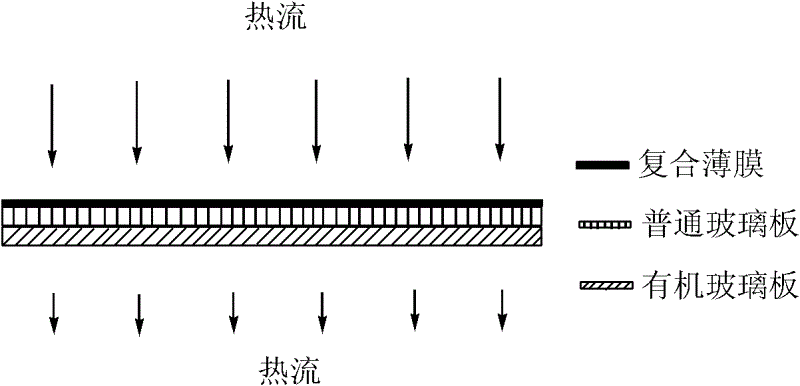

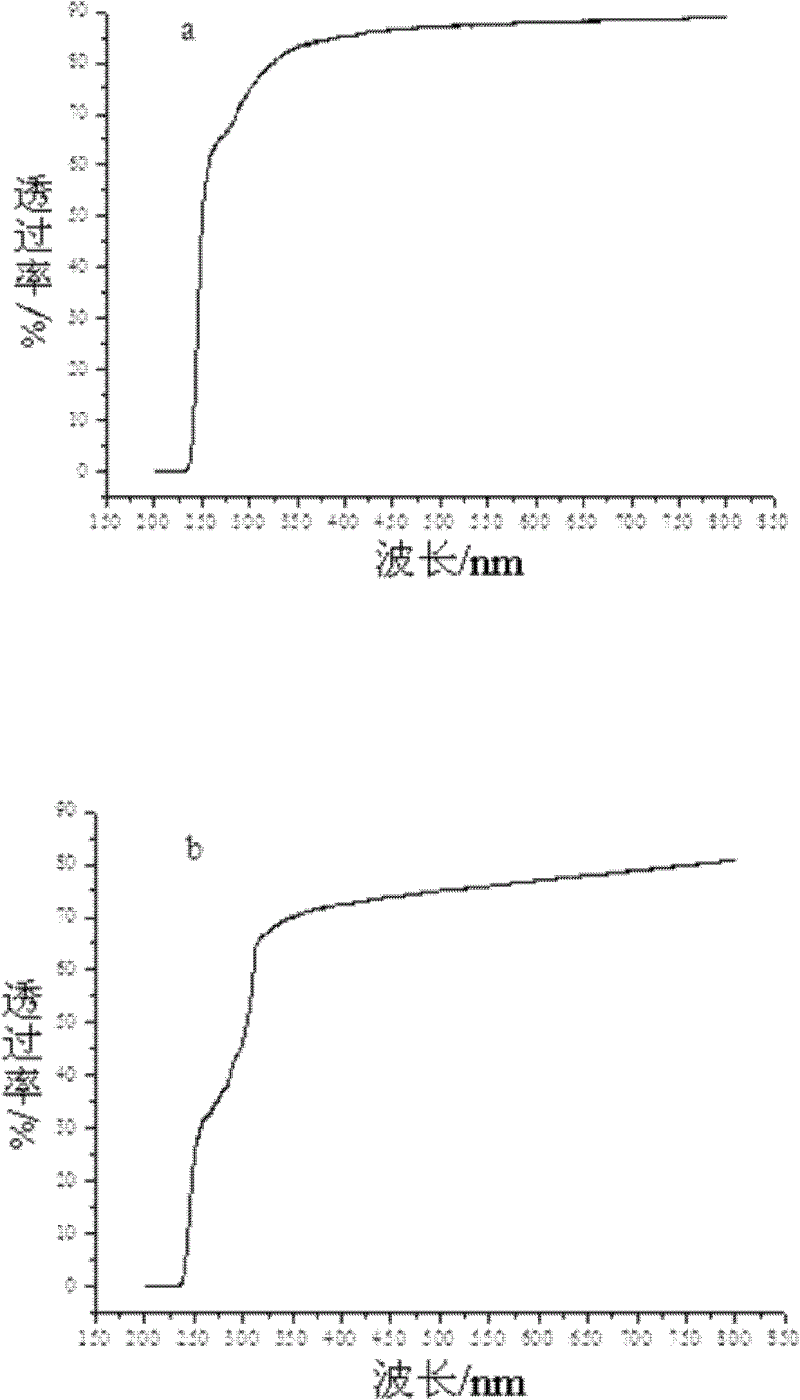

[0043] 0.5g SiO with a hollow size of 375nm 2 Hollow sphere with a wall thickness of 40nm dispersed in 100mL toluene solution containing 10mL KH550, refluxed at 110°C for 5h, separated after the solution is cooled, washed with ethanol three times, and then dispersed to a solution containing 4mL hydrochloric acid (1M) In 20mL ethanol solution, stirred for 3h, separated and washed, and finally dried at 80℃ for later use. Disperse part of the modified hollow sphere powder particles into the aqueous polyurethane emulsion (mass fraction 28%) to make the modified hollow sphere powder particles The mass is 0.25% of the mass of the waterborne polyurethane, mechanically stirred until the emulsion is slightly sticky, coated on the surface of the flat glass and then cast into a film. After 12 hours, it is baked at 35°C for 24 hours to obtain a composite film product. After testing, the thermal conductivity of the film is 0.05419W / mK, and the visible light region transmittance is over 80%. ...

Embodiment 2

[0045] 0.5g SiO with a hollow size of 375nm 2 Spherical powder with a wall thickness of 40nm dispersed in 100mL toluene solution containing 10mL KH570, refluxed at 110°C for 5h, separated after cooling the solution, washed three times with ethanol, dried at 80°C, and then dispersed to 35mL ethanol , Add 1g methyl methacrylate and a little azoisobutyronitrile to N 2 Protected and refluxed at 75℃ for 12h. The product was washed with acetone three times, and finally dried at 80℃ for later use. Part of the modified hollow sphere powder was dispersed into the aqueous polyurethane emulsion (mass fraction 28%) to make the modified hollow sphere powder The mass of the particles is 0.25% of the mass of the water-based polyurethane, mechanically stirred until the emulsion is slightly sticky, and coated on the surface of the flat glass to be cast into a film. After 12 hours, the particles are dried at 35°C for 24 hours to obtain a composite film product. After testing, the thermal conducti...

Embodiment 3

[0047] Take SiO with a hollow size of 200nm and a wall thickness of 20nm 2 The hollow spherical particles are additives, and the others are the same as in Example 1. After testing, the thermal conductivity of the film is 0.05513W / mK, and the transmittance in the visible light region is over 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com