Ceramic sheathed internal combustion engine piston and manufacturing method thereof

A manufacturing method and internal combustion engine technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve the problems of internal combustion engine combustion chamber temperature reduction, low thermal conductivity, brittle and brittle ceramic materials, etc., to reduce heat loss, increase heat engine efficiency, The effect of reducing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

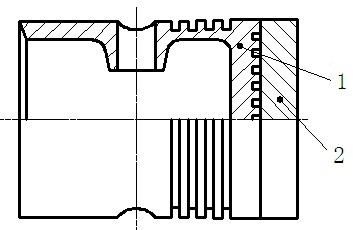

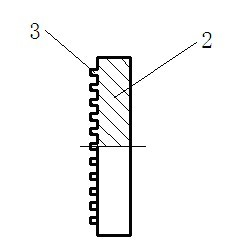

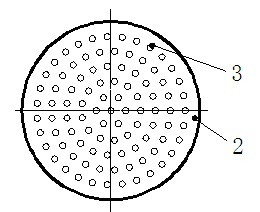

[0027] Embodiment 1: as figure 1 Shown is a ceramic armored internal combustion engine piston, including a metal body piston 1 and a ceramic top plate 2, the ceramic top plate 2 is cast on the top of the metal metal body piston 1; the outer surface and size of the ceramic top plate 2 meet the requirements of the top of the piston, that is, the ceramic top plate 2 The shape and size of the outer surface are the same as the top of the metal piston, and a plurality of ceramic nails 3 are evenly distributed on the inner surface of the ceramic top plate 2. One end of each ceramic nail 3 is connected to the inner surface of the ceramic top plate 2, and the other end is embedded in the metal. body piston 1.

[0028] Wherein, the thickness of the ceramic top plate 2 is 5 mm, and the material is silicon nitride ceramics; the ceramic nail 3 is cylindrical, with a diameter of 5 mm and a height of 5 mm. The sum of the cross-sectional areas of all the ceramic nails 3 accounts for 30% of ...

Embodiment 2

[0036] Embodiment 2: basically the same as Embodiment 1, the difference is the requirements of ceramic top plate 2 and ceramic nail 3, and the heating temperature in step 3) during preparation;

[0037] Wherein ceramic top plate 2 adopts alumina ceramics, and its wall thickness is 8mm; The thickness of ceramic top plate 2 is 8mm, and material is alumina ceramics; Ceramic nail 3 is cylindrical, and its diameter is 8mm, and height is 8mm; All ceramic nails 3 The sum of the cross-sectional areas accounts for 20% of the area of the ceramic top plate 2 .

[0038] During preparation, in step 3), the ceramic top plate 2 or the integral casting sand mold is heated to 700°C and then cast.

[0039] Compared with similar models, the invention can reduce the heat dissipation loss of the piston by 20%, increase the temperature of the combustion chamber of the cylinder by 200°C, and increase the heat engine efficiency by 10%.

Embodiment 3

[0040] Embodiment 3: basically the same as Embodiment 1, the difference is the requirements of ceramic top plate 2 and ceramic nail 3, and the heating temperature in step 3) during preparation;

[0041]The ceramic top plate 2 is made of silicon oxide ceramics, and its wall thickness is 10 mm; the thickness of the ceramic top plate 2 is 5 mm to 10 mm. The ceramic nail 3 is cylindrical, with a diameter of 10 mm and a height of 10 mm. The sum of the cross-sectional areas of all the ceramic nails 3 accounts for 25% of the area of the ceramic top plate 2 .

[0042] During preparation, in step 3), the ceramic top plate 2 or the integral casting sand mold is heated to 800°C and then cast.

[0043] Compared with similar models, the invention can reduce the heat dissipation loss of the piston by 15%, increase the temperature of the combustion chamber of the cylinder by 150°C, and increase the heat engine efficiency by 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com