Composite type antitranspirant, preparation method and application thereof

An anti-transpiration agent and a composite technology, applied in the field of anti-transpiration preparations, can solve the problems of affecting photosynthesis, environmental pollution, and high cost, and achieve the effects of low cost, improved survival time, and inhibition of stomatal opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of a single film-forming agent:

[0027] Prepare the film-forming agent with distilled water, the formula is: 2g / L sodium alginate, 2g / L CaCl 2 , 6g / L glucose;

[0028] 2. Preparation of composite anti-transpiration agent:

[0029] (1) Preparation of Bacteria A: Active dry yeast powder, at a ratio of 5g / L, was activated in normal saline at a temperature of 30°C for 30-60 minutes, then added 2g / L sodium alginate, and stirred evenly to prepare Bactericidal agent A;

[0030] (2) Preparation of film-forming agent B: prepare film-forming agent B with distilled water, the formula is: 2g / L CaCl 2 , 6g / L glucose;

[0031] (3) Preparation of compound anti-transpiration agent: Mix bacterial agent A and film-forming agent B when using, spray bacterial agent A on the surface of plant leaves first, and then spray film-forming agent B on the surface of plant leaves to form Composite anti-transpiration agent coated with film-forming agent.

[0032] 3. Processing m...

Embodiment 2

[0036] 1. Preparation of single yeast agent:

[0037] With reference to the method provided in Example 2 of the published invention patent "Preparation Method of Plant Anti-Transpiration Based on Saccharomyces cerevisiae" (CN100519734), a single yeast agent was prepared. details as follows:

[0038] (1) Preparation of bacterial agent a

[0039] Saccharomyces cerevisiae strains (the strains are from the China General Microorganism Culture Collection and Management Center, collection number CGMCC2.1) were inoculated into the sterilized culture medium, and cultured on a shaker under the conditions of 28°C and 150 rpm. 24 hours. The culture was then inactivated at 121°C for 90 minutes at a pressure of 0.12 MPa. After cooling, centrifuge at 6000 rpm for 40 minutes, remove the supernatant, dehydrate the precipitate with absolute ethanol to obtain bacterial agent a, and freeze it at -20°C.

[0040] (2) preparation of adjuvant b

[0041] Prepare adjuvant b with sterile water, the f...

Embodiment 3

[0056] 1. Preparation of compound anti-transpiration agent

[0057] 1) Preparation of bacterial agent A:

[0058] Activate the active dry yeast powder at a ratio of 5g / L in physiological saline at a temperature of 30°C for 30-60 minutes, then add 2g / L sodium alginate, and stir evenly to prepare bacterial agent A;

[0059] 2) Preparation of film-forming agent B:

[0060] Prepare film-forming agent B with distilled water, the formula is: 2g / L CaCl 2 , 6g / L glucose;

[0061] 3) Preparation of composite anti-transpiration agent:

[0062] Spray the bacterial agent A on the surface of the plant leaves first, and then spray the film-forming agent B on the surface of the plant leaves to form a composite anti-transpiration agent in which the bacterial agent is wrapped by the film-forming agent.

[0063] 2. Approach

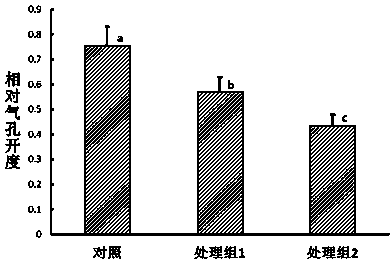

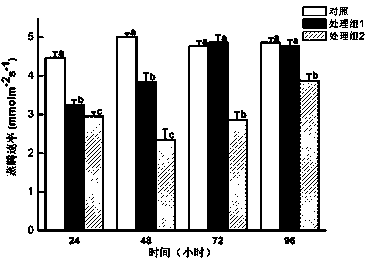

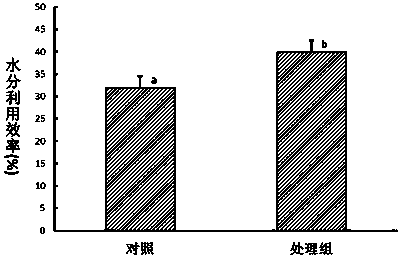

[0064] Spray the compound anti-transpiration agent evenly on the surface of faba bean leaves, measure the gas exchange data with CI-340 photosynthetic instrument (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com