Waste heat power generation system of marine diesel engine based on organic Rankine cycle

A marine diesel engine and Rankine cycle technology, applied in the direction of machine/engine, steam generation method using heat carrier, mechanical equipment, etc. The effect of eliminating possibility and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

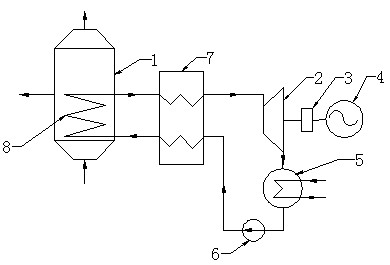

[0021] like figure 1 As shown, the system includes: exhaust gas boiler 1, steam turbine 2, speed reducer 3, generator 4, condenser 5, booster pump 6, heat exchanger 7 and evaporator 8 installed in the exhaust gas boiler. Among them, the booster pump 6 is used to compress the supercooled organic working fluid in the condenser 5 into a high-pressure supercooled liquid and then pump it into the heat exchanger 7; In the heat exchanger 7, the subcooled organic working medium is heated by the high-pressure superheated organic working medium gas from the evaporator 8; the evaporator 8 is used to generate high-pressure and low-superheated organic working medium steam; The superheated organic working medium steam expands to do work; the steam turbine 2 drives the alternator 4 through the reducer 3; the alternator 4 is used to generate electric energy suitable for use on board; the condenser 5 is used to cool the organic working medium steam to a low subcooling degree liquid.

[0022]...

Embodiment 2

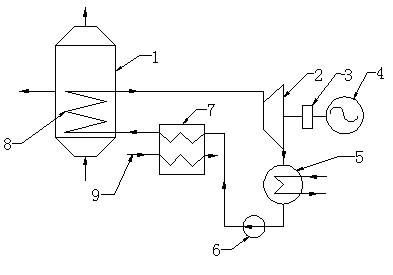

[0031] like figure 2 As shown, the system is a marine diesel waste heat power generation system based on organic Rankine cycle that can recover other waste heat at the same time. The difference between this embodiment and Embodiment 1 is: the high-pressure subcooled organic working fluid in the heat exchanger 7 is heated by the heating pipe 9 connected to the external heat source, and the external heat source can be other waste heat sources on board, such as the cooling water of the main engine cylinder jacket, High temperature pressurized air, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com