Oxidation reduction furnace and method for treating waste remained after dust-removal of iron and steel enterprises

A reduction furnace and waste technology, applied in waste heat treatment, furnaces, vertical furnaces, etc., can solve the problems of increased energy consumption, large heat loss, circulation pollution, etc., to avoid damage and agglomeration, reduce collision and friction, restore full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

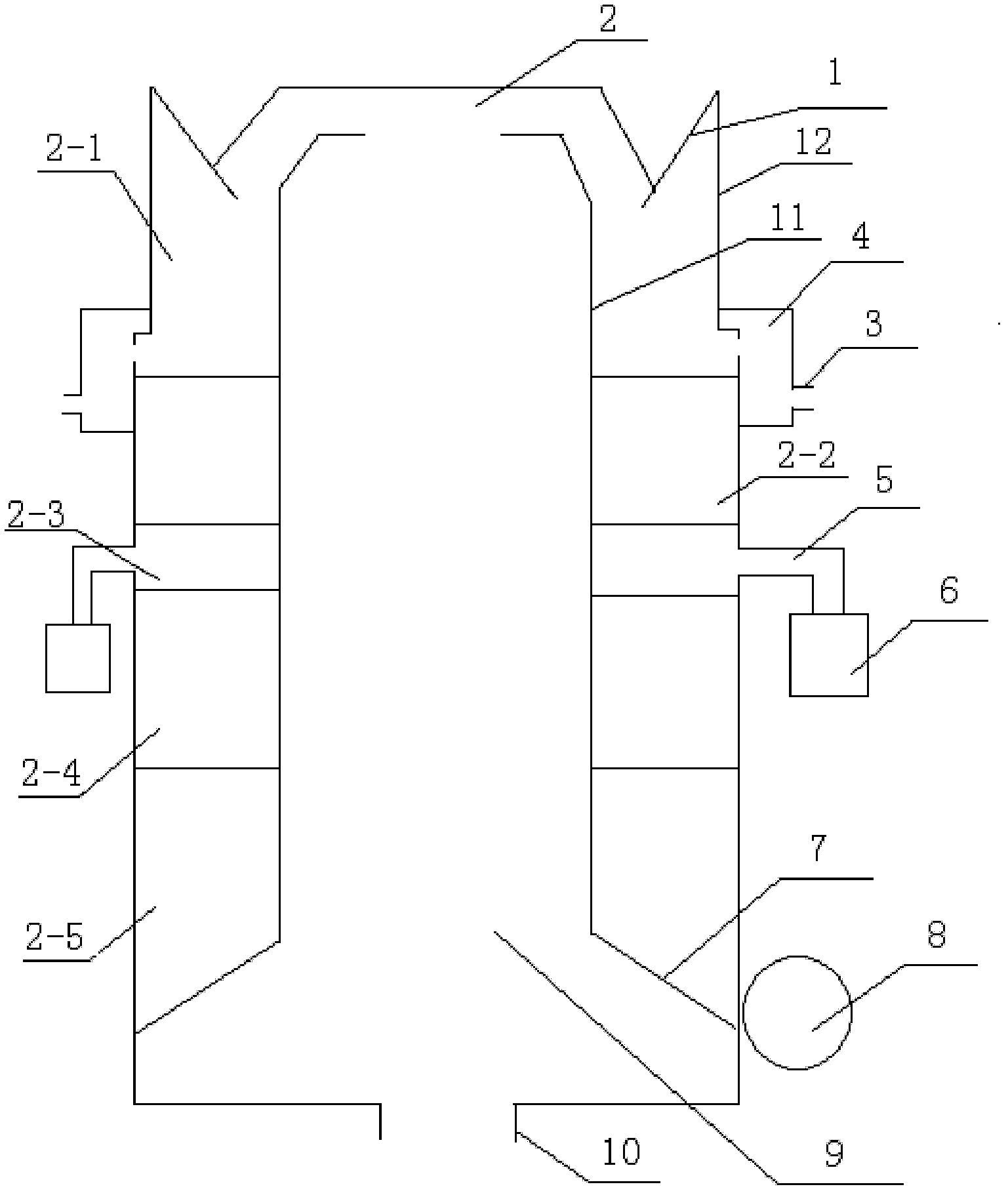

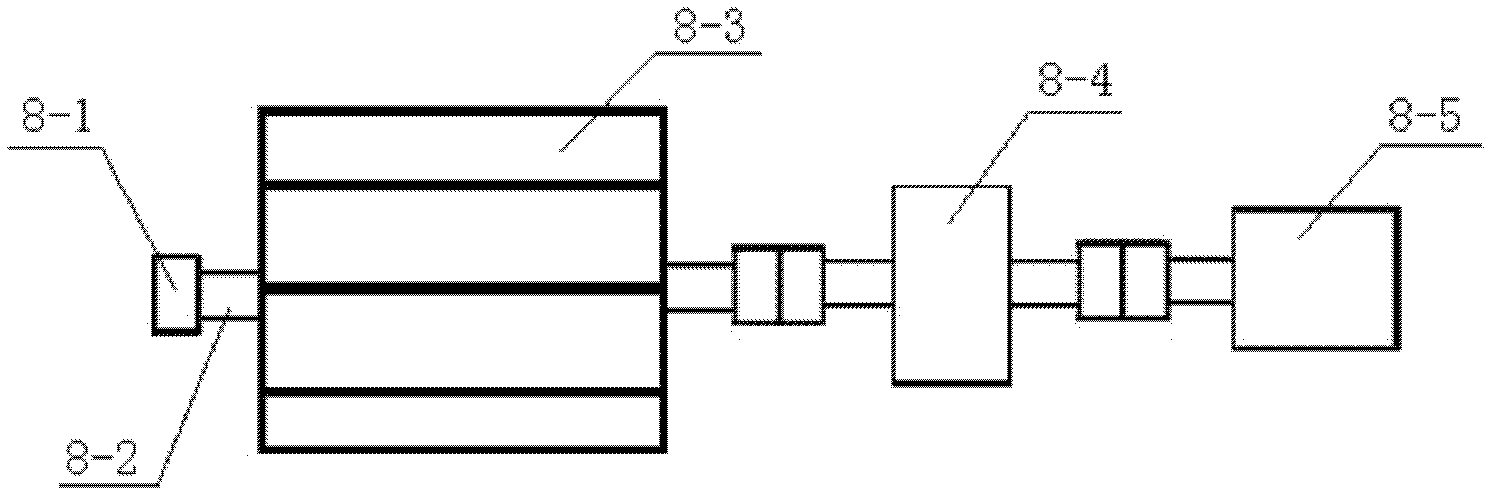

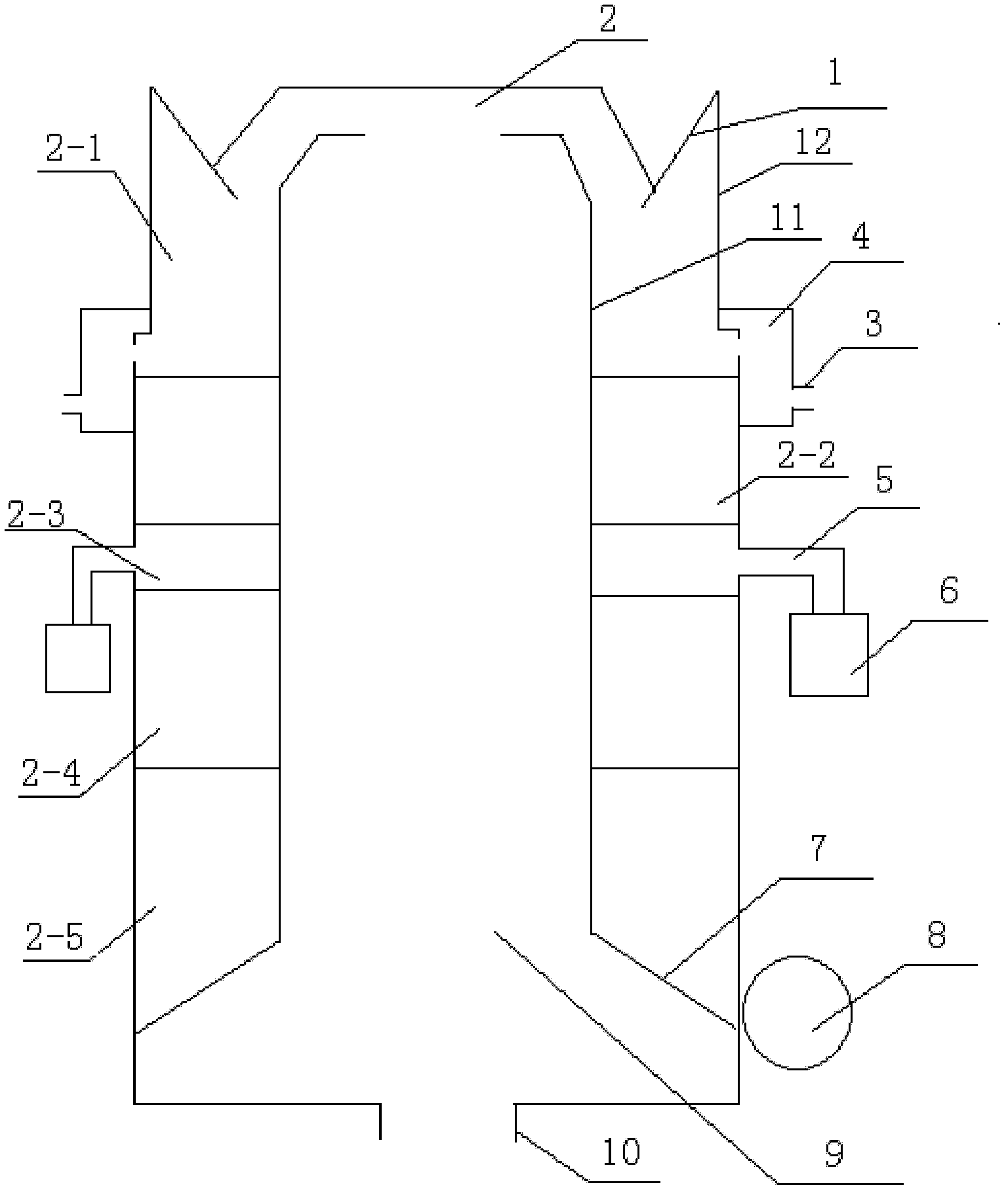

[0030] Embodiment 1: a kind of redox furnace (see Figure 1-2 ), characterized in that it consists of a hopper 1, furnace inner wall 11, furnace outer wall 12, flue 9, furnace cavity 2, combustion chamber 4, gas nozzle 3, gas channel 5, gas electromagnetic heater 6, lower hopper 7, lower The feeder 8 and the gas outlet 10 are formed; the hopper 1 is located at the top of the redox furnace; the flue 9 is the space within the furnace inner wall 11; the furnace cavity 2 is the furnace inner wall 11 and the furnace outer wall 12 The overall space between them is divided into preheating oxidation zone 2-1, reduction zone 2-2, gas zone 2-3, cooling zone 2-4 and discharge zone 2-5 from top to bottom according to the working temperature ; Said combustion chamber 4 is located at the side of the oxidation-reduction furnace, and is fixedly connected with the outer wall 12 of the furnace; said gas nozzle 3 is fixed on the combustion chamber 4; The gas belt 2-3 in 2 is connected; said low...

Embodiment 2

[0047] Embodiment 2: A redox furnace, characterized in that it consists of a hopper 1, furnace inner wall 11, furnace outer wall 12, flue 9, furnace cavity 2, combustion chamber 4, gas nozzle 3, gas channel 5, gas electromagnetic heating device 6, hopper 7, feeder 8 and gas outlet 10; said hopper 1 is located at the top of the redox furnace; said flue 9 is the space within the inner wall 11 of the furnace; said furnace chamber 2 It is the overall space between the furnace inner wall 11 and the furnace outer wall 12. According to the temperature difference during operation, it is divided into preheating oxidation zone 2-1, reduction zone 2-2, gas zone 2-3, and cooling zone 2-2 from top to bottom. 4 and discharge interval 2-5; said combustion chamber 4 is located at the side of the redox furnace, and is fixedly connected with the furnace outer wall 12; said gas nozzle 3 is fixed on combustion chamber 4; said gas electromagnetic heater 6 communicates with the gas belt 2-3 in the ...

Embodiment 3

[0065] A redox furnace, characterized in that it consists of a hopper 1, a furnace inner wall 11, a furnace outer wall 12, a flue 9, a furnace chamber 2, a combustion chamber 4, a gas nozzle 3, a gas channel 5, a gas electromagnetic heater 6, a lower The hopper 7, the feeder 8 and the gas outlet 10 are composed; the hopper 1 is located at the top of the redox furnace; the flue 9 is the space inside the inner wall 11 of the furnace; the furnace chamber 2 is the inner wall 11 of the furnace. The overall space between the furnace outer wall 12 is divided into preheating oxidation zone 2-1, reduction zone 2-2, gas belt 2-3, cooling zone 2-4 and discharge zone from top to bottom according to the temperature difference during operation. Interval 2-5; said combustion chamber 4 is located at the side of the oxidation-reduction furnace, and is fixedly connected with the outer wall 12 of the furnace; said gas nozzle 3 is fixed on the combustion chamber 4; said gas electromagnetic heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com