Method for producing edible fungi flavoring powder

A production method and technology of seasoning powder, which are applied in the field of new biological products, can solve the problems of blackening, no original fragrance, product deformation, etc., and achieve the effect of strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

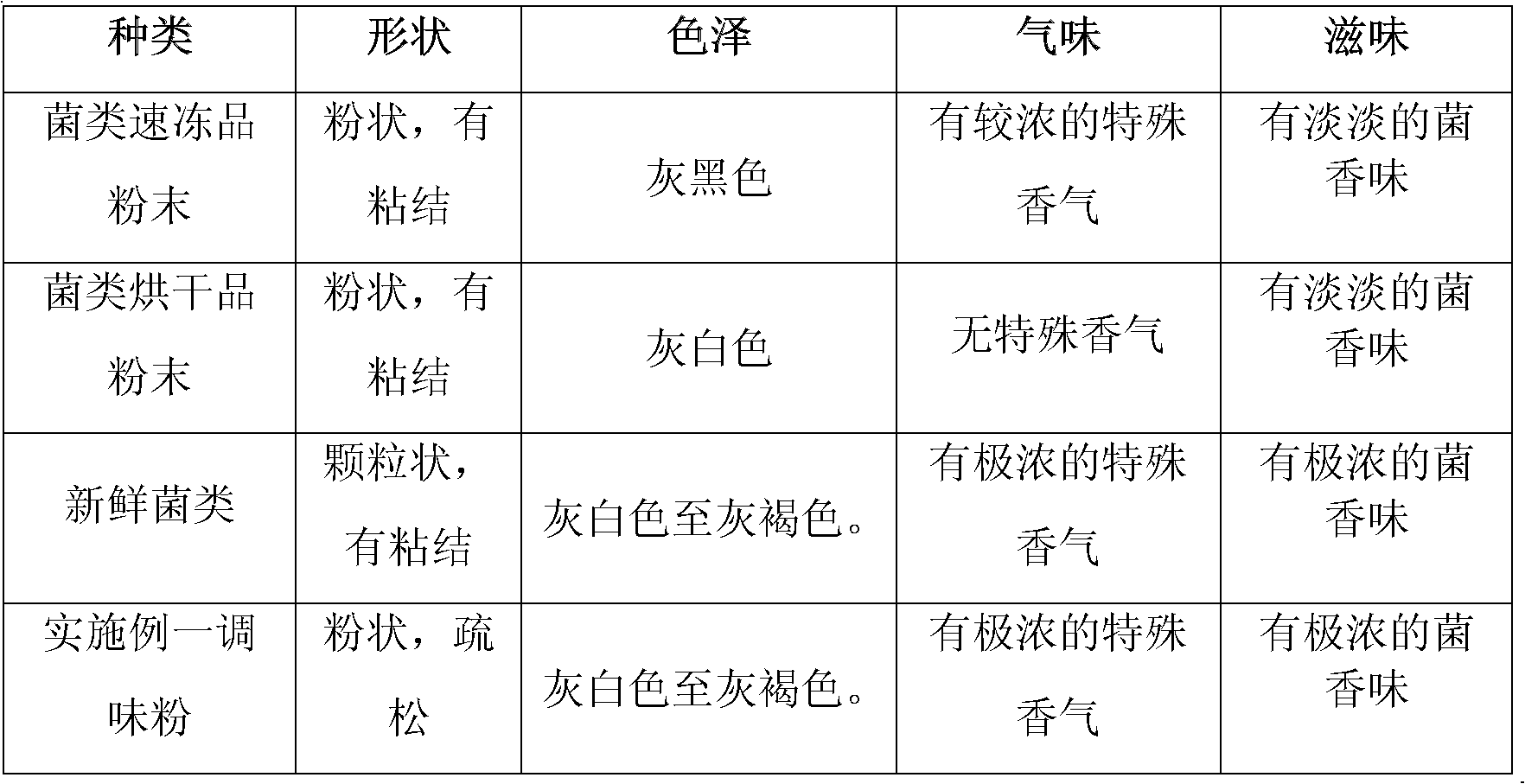

Examples

Embodiment 1

[0050] A. Raw material preparation: collect truffle, matsutake, morel, boletus, and black tiger palm 5 kinds of wild fresh edible fungi, wash, cut into thin slices, and put them in edible ethanol containing 0.2% citric acid and 0.04% TBHQ Soak for 1min, and dry the surface moisture at 5°C.

[0051] B. Freeze-drying: put the raw material processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 1°C / min, the final freezing temperature is -30°C, and keep warm for 1h. Vacuum the dryer to 40Pa, control the drying temperature at -20°C, and dry for 4 hours. Then the drying temperature was raised to 40° C. (heating rate 1° C. / min), the vacuum pressure was gradually reduced to 8 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of five kinds of fungi.

[0052] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in step B, and pass through a 100-mesh sieve to obtain freeze-dried powders of various fungi.

[0053] D....

Embodiment 2

[0061] A. Raw material preparation: collect truffles, Hericium erinaceus, chanterelles, shiitake mushrooms, and Pleurotus eryngii 5 kinds of fresh edible fungi, wash them, cut them into thin slices, and soak them in edible ethanol containing 0.3% citric acid and 0.08% TBHQ 2min, dry the surface moisture at 8°C.

[0062] B. Freeze-drying: put the raw materials processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 2°C / min, the final freezing temperature is -25°C, and the temperature is kept for 2 hours. Vacuum the dryer to 40Pa, control the drying temperature at -25°C, and dry for about 3 hours. Then the drying temperature was raised to 45° C. (heating rate 2° C. / min), the vacuum pressure was gradually reduced to 10 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of various fungi.

[0063] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in B, and pass through a 100-mesh sieve to obtain freeze-dried ...

Embodiment 3

[0072] A. Raw material preparation: collect truffles, pine milk mushrooms, jitake mushrooms, collybia mushrooms, tea tree mushrooms, and russula 6 kinds of fresh edible fungi, wash them, cut them into thin slices, and put them in the 0.2% citric acid and 0.03% TBHQ Soak in edible ethanol for 2 minutes, and dry the surface moisture at 5°C.

[0073] B. Freeze-drying: put the raw material processed in step A into a vacuum freeze dryer for freezing, the freezing speed is 1°C / min, the final freezing temperature is -30°C, and the temperature is kept for 2 hours. Vacuum the dryer to 35Pa, control the drying temperature at -23°C, and dry for about 4 hours. Then the drying temperature was raised to 40° C. (heating rate 2° C. / min), the vacuum pressure was gradually reduced to 8 Pa, and the drying time was 10 minutes to obtain freeze-dried sheets of various fungi.

[0074] C. Crushing and sieving: crush the freeze-dried sheets of various fungi dried in step B, and pass through a 100-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com