Three-dimensional non-support bone repairing patch and preparation method thereof

A non-supporting, bone repair technology, applied in medical science, prosthesis, etc., can solve the problems of difficult cell planting and penetration, and achieve the effect of excellent biocompatibility, good biocompatibility, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

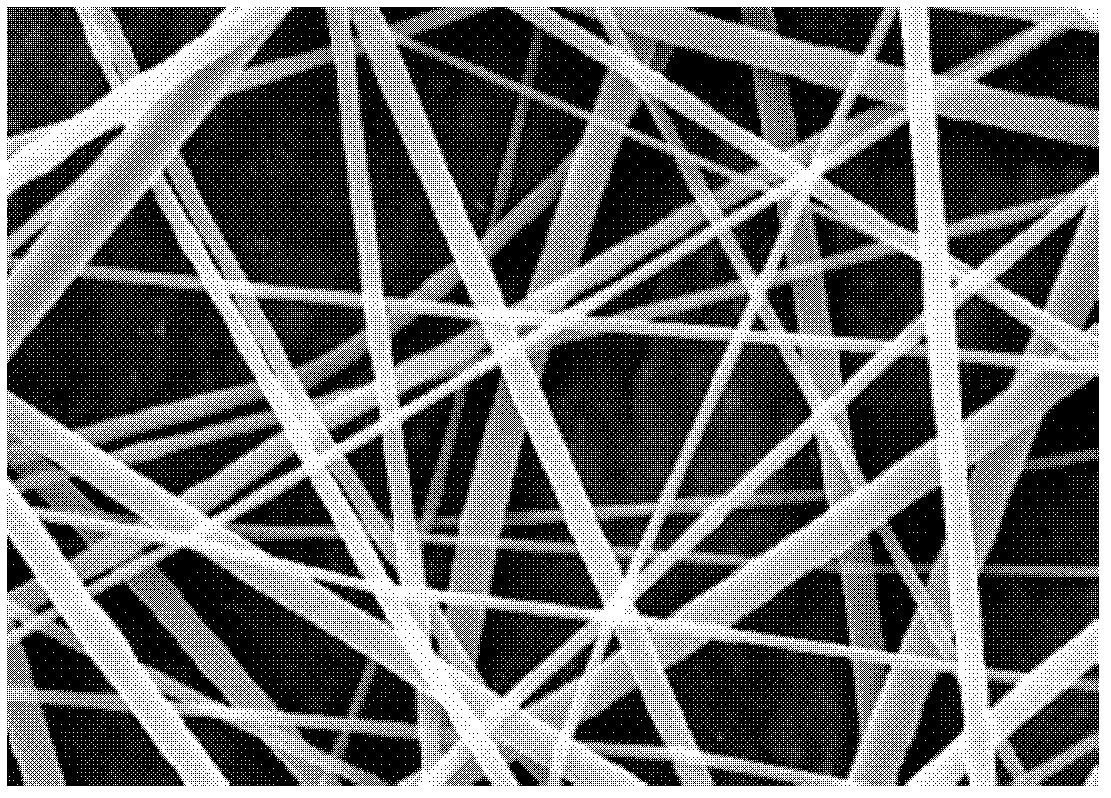

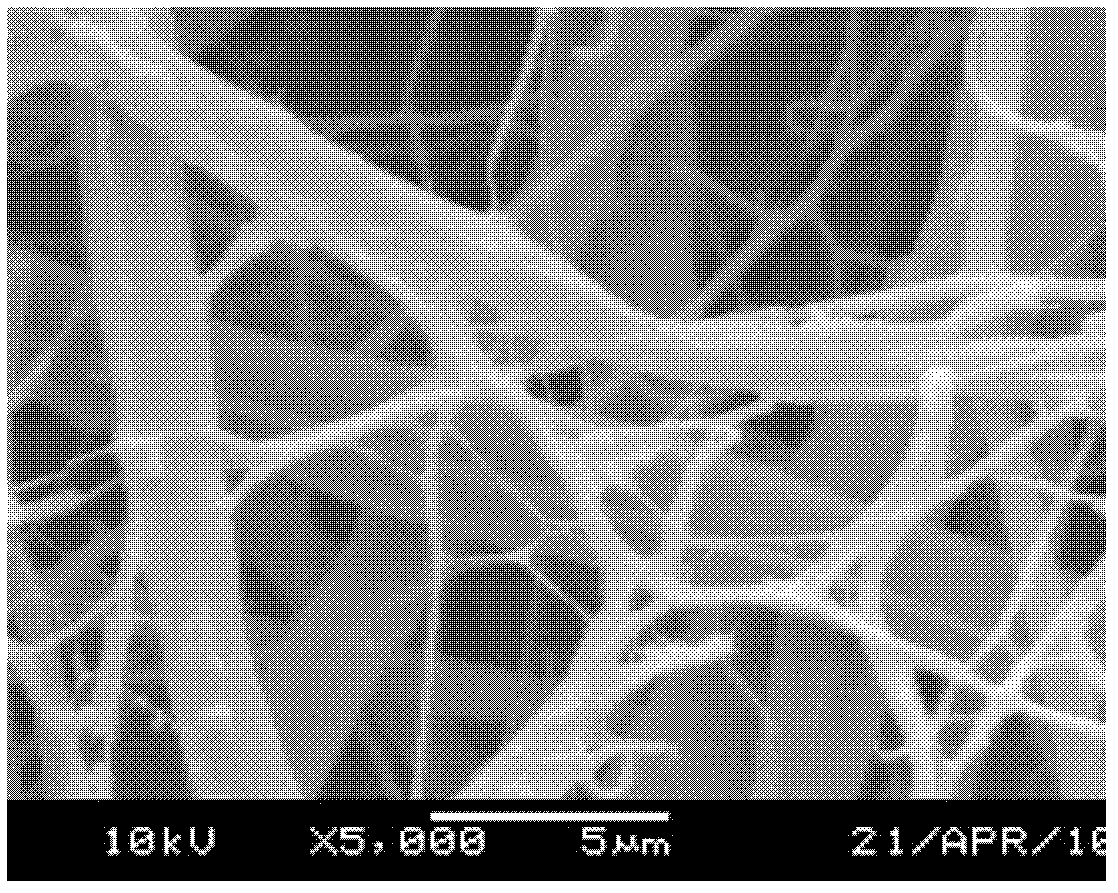

[0034] (1) Preparation of fiber scaffold

[0035] Dissolve PCL and PGA in trifluoroacetic acid at a mass ratio of 9:1 to prepare a 20% solution. Stir with a magnetic stirrer to obtain a transparent and uniform electrospinning solution;

[0036] The prepared electrospinning stock solution was electrospun, and the spinning parameters were controlled at a voltage of 15kv, a nozzle aperture of 0.4mm, a solution flow rate of 1ml / h, an ambient temperature of 20°C, and a distance of 15cm between the flat receiving device and the nozzle.

[0037] (2) Preparation of unsupported bone patch

[0038] After the electrospinning, the fiber support was removed from the flat receiving device, immersed in ethanol for 48 hours, and then vacuum-dried. Cut into a three-dimensional shape of length 5cm×width 5cm×thickness 0.5mm, and sterilize.

Embodiment 2

[0040] (1) Preparation of fiber scaffold

[0041] Dissolve PCL and PGA in trifluoroacetic acid at a mass ratio of 5:5 to prepare a 10% solution. Stir with a magnetic stirrer to obtain a transparent and uniform electrospinning solution;

[0042] The prepared electrospinning stock solution was electrospun, and the spinning parameters were controlled at a voltage of 20kv, a nozzle aperture of 0.7mm, a solution flow rate of 2ml / h, an ambient temperature of 25°C, and a distance between the winding drum (diameter of 50cm) and the nozzle of 5cm. The winding speed is controlled at 200rpm

[0043] (2) Preparation of unsupported bone patch

[0044] After electrospinning, the fiber support was removed from the winding drum, immersed in ethanol for 48 hours, and then vacuum-dried. Cut into a three-dimensional shape with a certain radian (length 5cm×width 5cm×thickness 0.5mm), and sterilize.

Embodiment 3

[0046] (1) Preparation of fiber scaffold

[0047] Dissolve PCL and PGA in hexafluoroisopropanol at a mass ratio of 5:5 to prepare a 5% solution. Stir with a magnetic stirrer to obtain a transparent and uniform electrospinning solution;

[0048]The prepared electrospinning stock solution was electrospun, and the spinning parameters were controlled at a voltage of 5kv, a nozzle aperture of 1mm, a solution flow rate of 0.5ml / h, an ambient temperature of 25°C, and a distance between the winding drum (diameter of 5cm) and the nozzle of 5cm. The winding speed is controlled at 4000rpm

[0049] (2) Preparation of unsupported bone patch

[0050] After electrospinning, the fiber support was removed from the winding drum, immersed in the organic solvent ethanol for 48 hours, and then vacuum-dried. It is cut into the three-dimensional shape of the repaired brain patch and sterilized for bone marrow mesenchymal stem cell culture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com