Preparation method of copper-titanium-oxide mesomorphism material

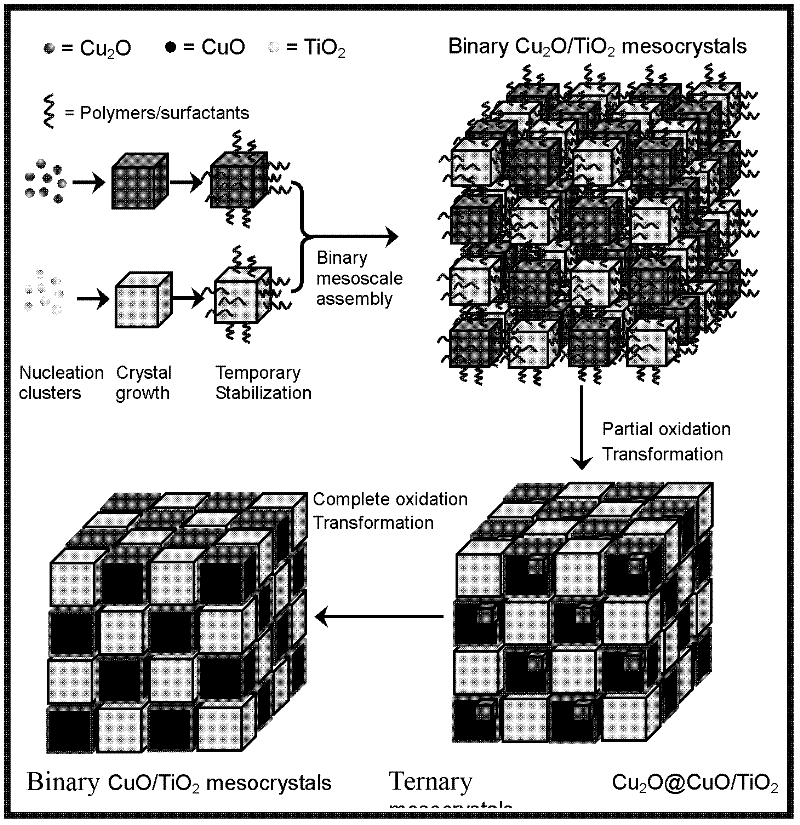

A titanium oxide and mesogen technology is applied in the field of preparation of functional materials, which can solve the problems of low solar energy utilization efficiency and narrow spectral response range, and achieve the effects of adjustable energy band structure, low preparation cost and low impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

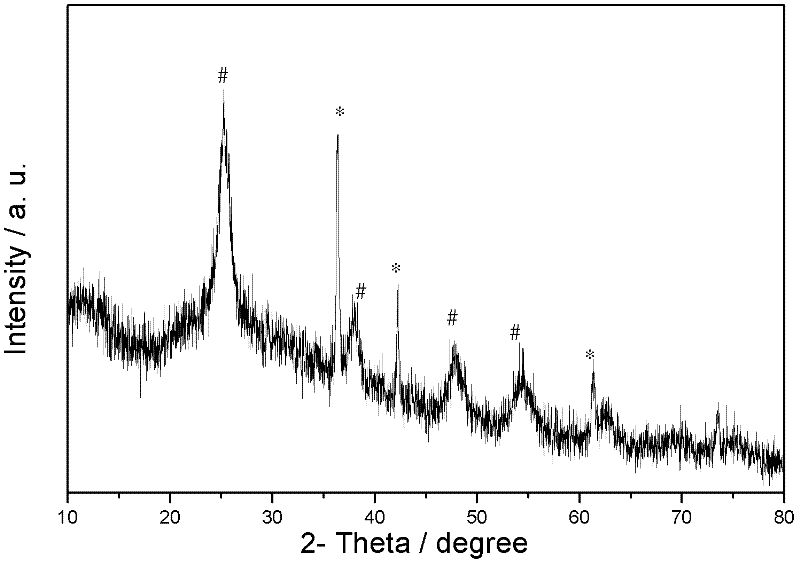

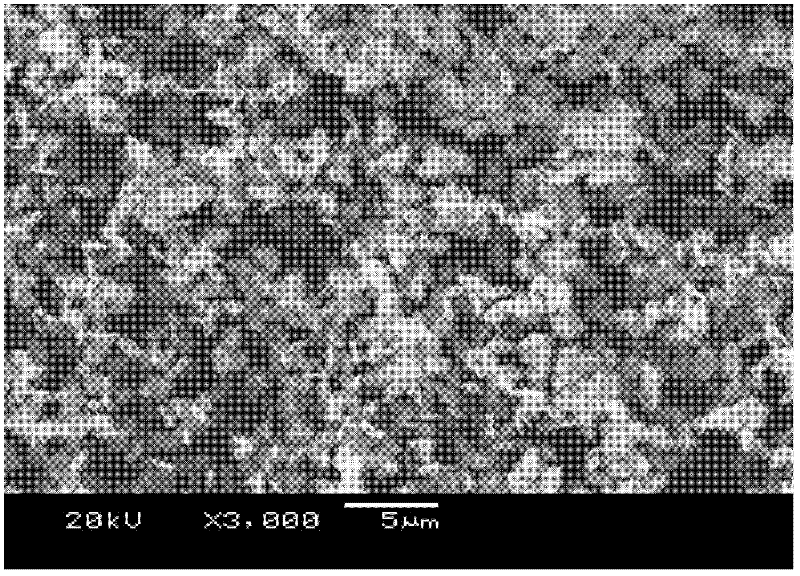

[0036] Slowly add the mixed solution of copper chloride alcohol and water with a concentration of 0.1 mol / L to the mixed solution of tetrabutyl titanate alcohol and water with a concentration of 0.1 mol / L, and add octadecylamine during the mixing process. Wherein the mixed solution of alcohol and water is prepared by ethanol and water according to v:v=1:1, in the mol ratio of cupric chloride / tetrabutyl titanate=0.2:1, octadecylamine is 1% (mol) of cupric chloride ), stirred and reacted for 20 minutes with 70 rpm stirring speed. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the completion of the hydrothermal reaction, cool to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 4 hours at 40°C to obtain Cu 2 O-TiO 2 mesogenic material ( figure 2 and image 3 ). Will Cu 2 O-TiO 2 Put...

Embodiment 2

[0039] Slowly add the mixed solution of copper nitrate alcohol and water with a concentration of 0.1 mol / L to the mixed solution of tetrabutyl titanate alcohol and water with a concentration of 0.1 mol / L, and add octadecylamine during the mixing process. Wherein the mixed solution of alcohol and water is prepared by ethanol and water according to v:v=1:1, in the mol ratio of copper nitrate / tetrabutyl titanate=0.2:1, octadecylamine is 1% (mol) of copper nitrate, The reaction was stirred at a stirring speed of 70 rpm for 20 minutes. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 180° C., and the hydrothermal reaction time was 24 hours. After the completion of the hydrothermal reaction, cool to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 4 hours at 40°C to obtain Cu 2 O-TiO 2 mesogenic material. Will Cu 2 O-TiO 2 Put the mesogenic material in...

Embodiment 3

[0042] Slowly add the mixed solution of copper nitrate alcohol and water with a concentration of 0.1 mol / L to the mixed solution of tetrabutyl titanate alcohol and water with a concentration of 0.1 mol / L, and add sodium lauryl sulfate during the mixing process. Wherein the mixed solution of alcohol and water is prepared by ethanol and water according to v: v=1: 1, in the mol ratio of copper nitrate / tetrabutyl titanate=0.2: 1, sodium lauryl sulfate is 2% of copper nitrate ( mol), stirred and reacted for 20 minutes with a stirring speed of 70 rev / min. The obtained mixed solution was subjected to hydrothermal reaction, the hydrothermal reaction temperature was 160° C., and the hydrothermal reaction time was 48 hours. After the completion of the hydrothermal reaction, cool down to room temperature naturally, filter and wash the product obtained by the reaction, put it in an oven, and dry it for 3 hours at 40°C to obtain Cu 2 O-TiO 2 mesogenic material. Will Cu 2 O-TiO 2 Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com