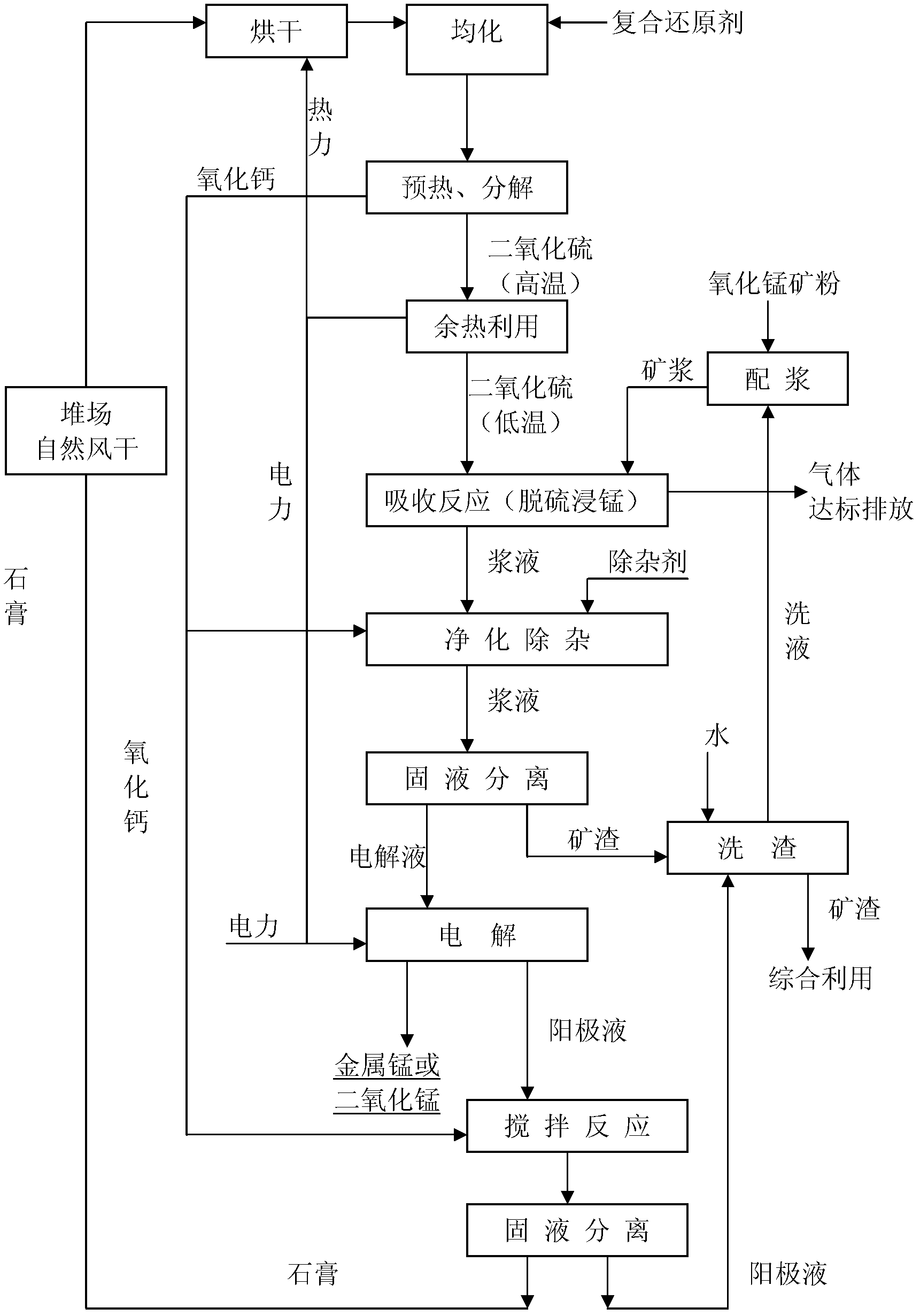

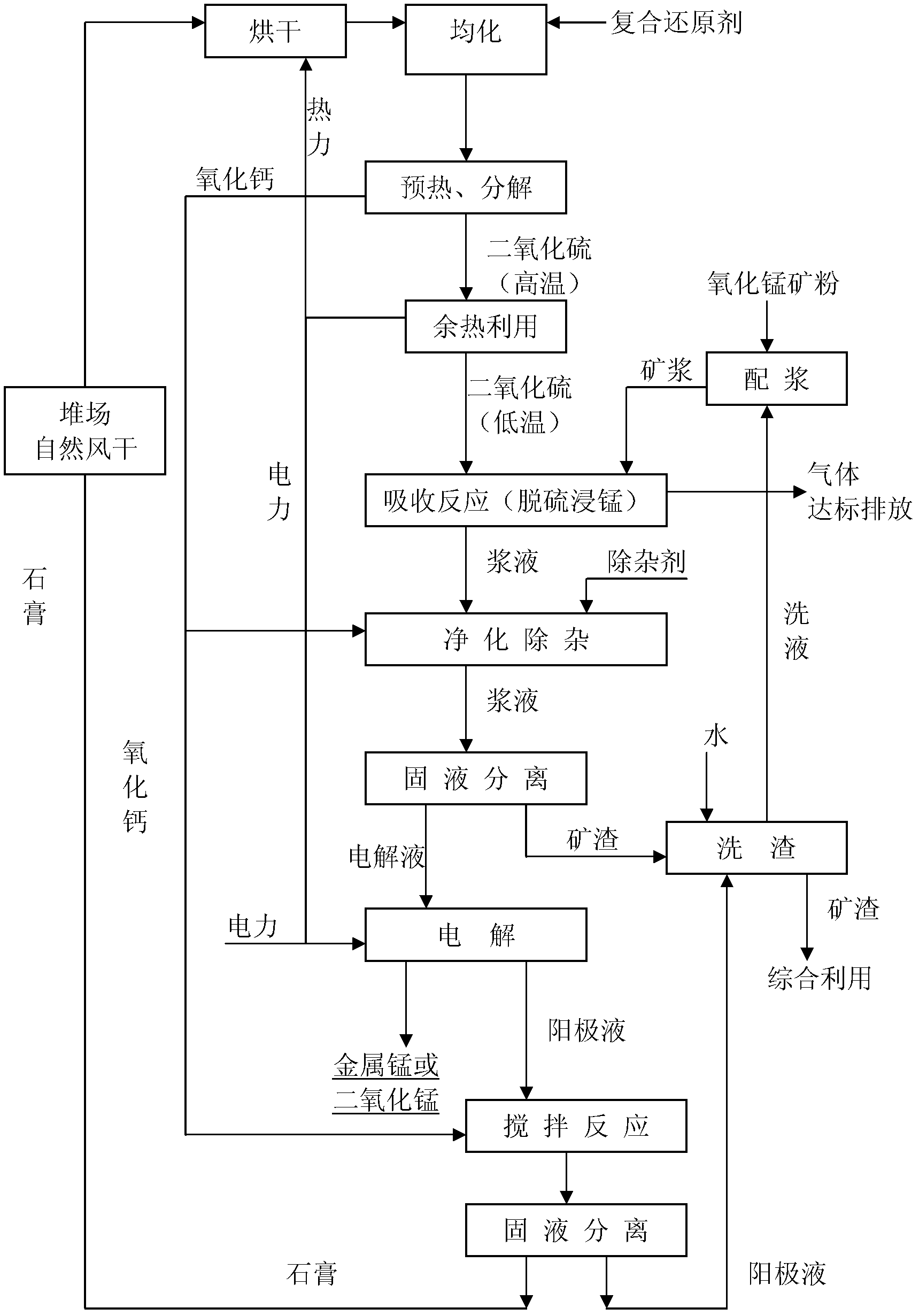

Method for preparing electrolytic manganese/electrolytic manganese dioxide by cyclically leaching manganese oxide with sulfur and calcium

A technology for electrolytic manganese dioxide and manganese oxide, applied in the field of electrolytic manganese dioxide and preparation of electrolytic manganese, can solve the problems of wasting manganese resources, wasting sulfur resources, waste water pollution, etc. surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Crushing and drying of gypsum: The gypsum generated from the anolyte sulfuric acid and calcium oxide from the subsequent electrolysis process is naturally air-dried and crushed, and then it is in contact with the high-temperature gas from the subsequent gypsum decomposition in the disc dryer to evaporate the water. The gypsum is dried and dehydrated to become dihydrate gypsum containing 1% free water.

[0064] (2) Homogenization of raw materials: the gypsum produced by the system and the composite reducing agent made of coke and sulfur according to the mass ratio of 1:1, according to the composite reducing agent / SO 3 (molar ratio) is about 0.6 for homogenization.

[0065] (3) Preheating decomposition: send the above raw materials into the fluidized bed preheating decomposer for decomposition, the materials pass through the preheaters at various levels in turn, and finally preheat to 600°C, enter the decomposer for decomposition, and control the decomposition tempera...

Embodiment 2

[0075] (1) Crushing and drying of gypsum: the gypsum generated from the anolyte sulfuric acid and calcium oxide from the subsequent electrolysis process is naturally air-dried and crushed, and then it is in contact with the high-temperature gas from the subsequent gypsum decomposition in the suspension dryer to evaporate the water. The gypsum is dried and dehydrated to become dihydrate gypsum with 0.5% free water.

[0076] (2) Homogenization of raw materials: the gypsum produced by the system and the composite reducing agent made of coal and sulfur according to the mass ratio of 1:1, according to the composite reducing agent / SO 3 (molar ratio) is about 0.7 for homogenization.

[0077] (3) Preheating decomposition: send the above raw materials into the rotary kiln type preheating decomposer for decomposition, the materials pass through the preheaters at various levels in turn, and finally preheat to 650°C, enter the decomposer for decomposition, control the decomposition temper...

Embodiment 3

[0087] (1) Crushing and drying of gypsum: the gypsum generated from the anolyte sulfuric acid and calcium oxide from the subsequent electrolysis process is naturally air-dried and crushed, and then it is in contact with the high-temperature gas from the subsequent gypsum decomposition in the suspension dryer to evaporate the water. The gypsum is dried and dehydrated to become dihydrate gypsum with 0.6% free water.

[0088] (2) Homogenization of raw materials: the gypsum produced by the system and the composite reducing agent made of coke and pyrite in a mass ratio of 1:1, according to the composite reducing agent / SO 3 (molar ratio) is about 0.6 for homogenization.

[0089] (3) Preheating decomposition: The above-mentioned raw materials are sent to the fluidized furnace type preheating decomposer for decomposition, and the materials pass through the preheaters at various levels in turn, and finally preheated to 630°C, then enter the decomposer for decomposition, and the decompo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com