Hydrophobic separation membrane and preparation method

A hydrophobic, separation membrane technology, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low efficiency, high energy consumption, difficult to achieve engineering applications, etc. Drying problem, the effect of promoting large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

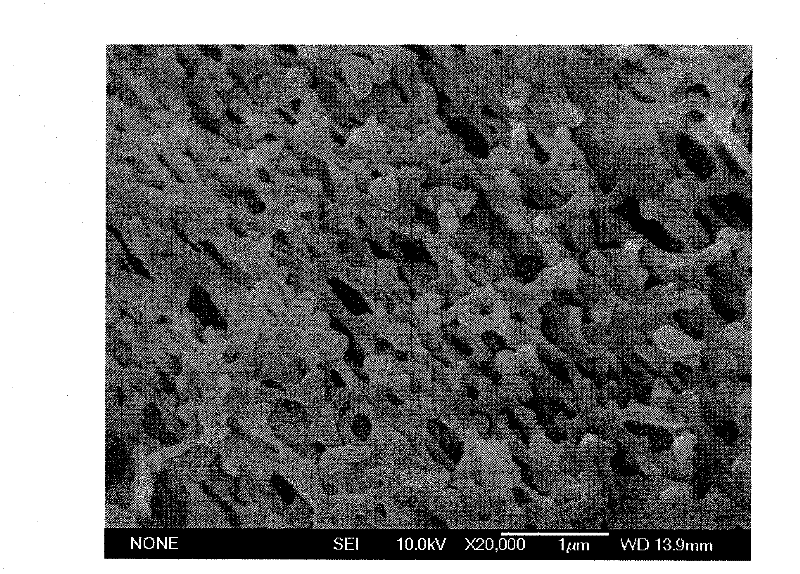

[0039] Prepare a coating solution, stir and dissolve polyvinylidene fluoride resin (Solef, 6010) and propylene glycol in dimethylacetamide solvent to obtain 1.5wt% polyvinylidene fluoride, 30wt% propylene glycol, and 68.5wt% dimethylacetamide After degassing, the coating solution is coated on the outer surface of a dry hydrophilic polyvinylidene fluoride hollow fiber microporous membrane with a pore size of 0.2 μm, and after being exposed to air for 30 seconds, it is solidified in water to form a film. The thickness of the hydrophobic layer of the obtained polyvinylidene fluoride hydrophobic membrane was 1.1 μm, the membrane separation pore size was still 0.20 μm, and the contact angle on the outer surface of the hollow fiber membrane was 163 degrees. The contact angle of the outer surface of the hydrophilic polyvinylidene fluoride hollow fiber base membrane is 57 degrees.

Embodiment 2

[0041] Stir and dissolve 10 grams of fluorosilicone rubber (Shanghai Sanaifu Company, FE2801) and 990 grams of methyl ethyl ketone, and defoam to prepare a casting solution. The casting solution is coated on the inner surface of a polyethersulfone hollow fiber membrane with a pore diameter of 0.2 μm and a thickness of 0.25 mm, and solidified in water to form a membrane. The membrane separation pore diameter of the obtained hydrophobic membrane was 0.20 μm, the thickness of the hydrophobic layer was 2.0 μm, and the contact angle of the inner surface of the hollow fiber membrane was 151 degrees. The contact angle of the inner surface of the polyethersulfone hollow fiber base membrane is 54 degrees.

Embodiment 3

[0043] 10 grams of fluororubber (Shanghai Sanaifu Company, FE2651) and 990 grams of methyl ethyl ketone were stirred and dissolved evenly, and defoaming was performed to prepare a casting solution. The casting solution is coated on the inner surface of a polysulfone hollow fiber membrane with a pore size of 0.2 μm, and solidified in water to form a membrane. The membrane separation pore diameter of the obtained hydrophobic membrane was 0.20 μm, the thickness of the hydrophobic layer was 2.0 μm, and the contact angle of the inner surface of the hollow fiber membrane was 137 degrees. The contact angle of the inner surface of the polysulfone hollow fiber base membrane is 58 degrees.

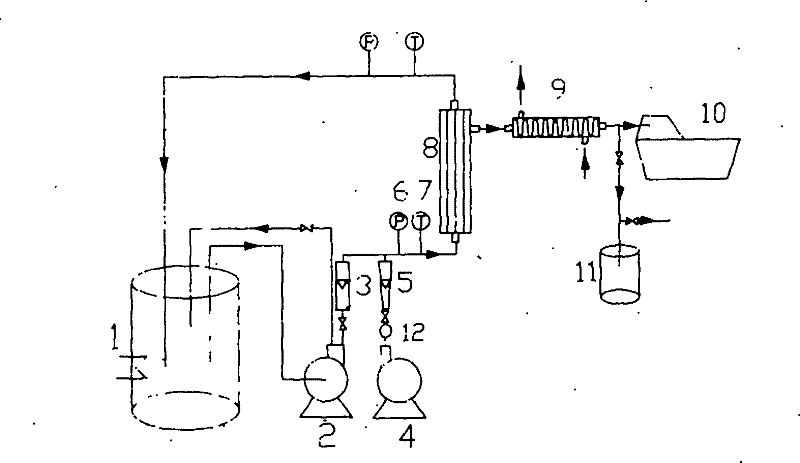

[0044] Description of vacuum membrane distillation experiment system

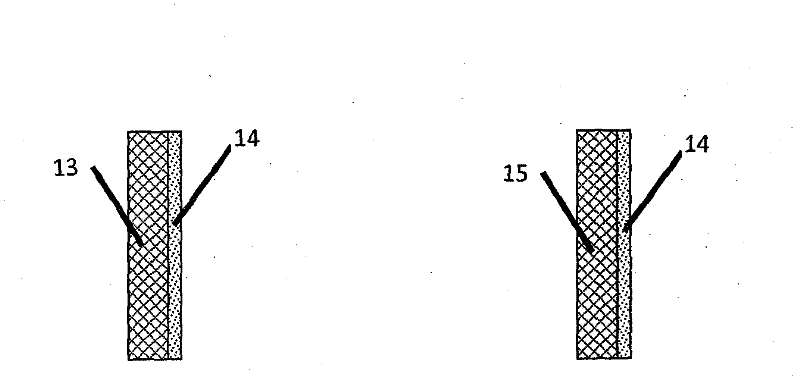

[0045] The process flow of the vacuum membrane distillation experimental system is as follows: figure 1 As shown, the system is mainly composed of two loops on the hot side and vacuum side and polyvinylidene fluoride hydrophobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com