Preparation method for high-temperature crosslinking agent for oil field tertiary oil recovery

A cross-linking agent and high-temperature technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the development and application of low-cost profile control and flooding systems in the middle and deep layers, health and environmental hazards of construction personnel, and system High toxicity and other problems, to achieve the effect of excellent thermal stability, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the high-temperature cross-linking agent for oilfield tertiary oil recovery is as follows: the high-temperature cross-linking agent is compounded from cross-linking agent A and cross-linking agent B.

[0029] The preparation method of crosslinking agent A: acetone: formaldehyde: organic amine = 1:2-4:2-3.5 (molar ratio), at a reaction temperature of 50-120 ° C, a reaction pressure of 0-0.3 MPa, stirring reaction 5- 8h, must contain two active groups (hydroxymethylene-CH 2 OH) crosslinking agent A, its reaction principle is:

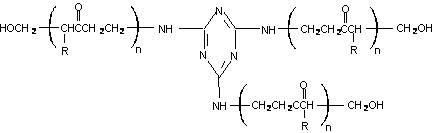

[0030]

[0031] where R is C 1 —C 18 Straight chain alkyl; n is an integer of 1-20.

[0032] The preparation method of crosslinking agent B is melamine: formaldehyde: ketone = 1:3—10:3-10 (molar ratio), at the reaction temperature of 75-95°C, the reaction pressure is 0-0.3MPa, and the reaction is stirred for 3-5h , to obtain three reactive groups (hydroxymethylene-CH 2 OH) cross-linking agent B, its reaction princi...

Embodiment 1

[0038]Synthesis of crosslinking agent A-1: 500ml four-neck flask equipped with thermometer, dropping funnel, reflux condenser and magnetic stirrer. Add 80g of distilled water into the four-neck flask, start stirring, dropwise add 110g of ethylamine aqueous solution (percentage concentration 70%), control the temperature at 40-50°C, after the dropwise addition, add 45g of acetone, raise the temperature to 75-80°C, drop 150g formaldehyde aqueous solution (percentage concentration 37%) is added dropwise within 1-1.5 hours. Then raise the temperature to 85-95°C and react for 6 hours to obtain crosslinking agent A (code A-1).

[0039] Synthesis of crosslinking agent B-1: 500ml four-neck flask equipped with thermometer, dropping funnel, reflux condenser and magnetic stirrer. Add 50g of distilled water and 50g of ethanol to a four-necked flask, add 35g of melamine and 78g of acetone, raise the temperature to 75-80°C, add 105g of formaldehyde solution (percentage concentration: 37%...

Embodiment 2

[0044] Synthesis of crosslinking agent A-2: 500ml four-necked flask equipped with thermometer, dropping funnel, reflux condenser and magnetic stirrer. Add 100g of distilled water into the four-necked flask, start stirring, dropwise add 78g of n-butylamine, control the temperature at 40-50°C, add 26g of acetone after the drop, raise the temperature to 75-80°C, add dropwise 110g of formaldehyde solution (percent concentration 37% ), the dropwise addition was completed in 1h. Then raise the temperature to 85-95°C and react for 6 hours to obtain crosslinking agent A (code A-2).

[0045] Synthesis of crosslinking agent B-2: 500ml four-neck flask equipped with thermometer, dropping funnel, reflux condenser and magnetic stirrer. Add 70g of distilled water and 80g of ethanol to a four-necked flask, add 20g of melamine and 127g of propiophenone, raise the temperature to 80-85°C, add 78g of formaldehyde solution (percentage concentration: 37%) dropwise, complete the dropwise addition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com