Preparation method of polymeric material by utilizing monosaccharide and methyl methacrylate or methyl acrylate

A technology of methyl methacrylate and methyl acrylate, applied in the field of preparation of monosaccharide-based derivatives, to achieve the effects of improving biodegradation and processability, wide sources, and good desorption and regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

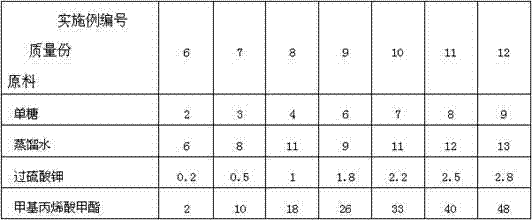

[0030] A method for preparing polymeric materials with monosaccharides and methyl methacrylate, comprising the following steps: dissolving 1 to 10 parts of mannose in 5 to 15 parts of distilled water, and then adding 0.1 to 3 parts of potassium persulfate (or Sodium sulfate or ammonium persulfate) as the initiator, stir well to dissolve the two (uniform dispersion), add 1 to 50 parts by mass of methyl methacrylate monomer to the above mixed solution, and stir at 20 to 100 ° C After reacting for 1-10 hours, cool naturally to room temperature, powder (chop) it with appropriate methods, wash with water, purify, and dry to constant weight at 30-80°C to obtain the final product.

Embodiment 2

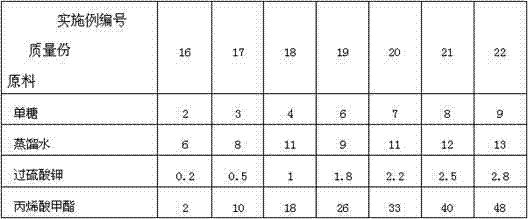

[0032] A method for preparing polymeric materials with monosaccharide and methyl acrylate, comprising the following steps: dissolving 1-10 parts of glucose in 5-15 parts of distilled water, and then adding 0.1-3 parts of potassium persulfate (or sodium persulfate or persulfate ammonium sulfate) as the initiator, fully stir to dissolve the two (uniformly dispersed), add 1 to 60 parts by mass of methyl acrylate monomer to the above mixed solution, and stir and react at 20 to 100°C for 1 to 12 hours Naturally cool to room temperature, use appropriate method to grind (cut) the powder, wash with water, purify, and then dry to constant weight at 20-100°C to obtain the final product.

Embodiment 3

[0034] A method for preparing polymeric materials with monosaccharide and methyl methacrylate, comprising the following steps:

[0035] a. Ingredients mixing: Dissolve 5 parts by mass of monosaccharide in 10 parts by mass of distilled water, then add 1.5 parts by mass of initiator potassium persulfate, (full) stir and mix (so that the solid dissolves or disperses evenly), and then adds 25 parts by mass The methyl methacrylate, obtains the reaction mixture;

[0036]b. Polymerization reaction: After the reaction mixture was stirred and reacted for 6 hours at a temperature of 60°C, it was naturally cooled to room temperature to obtain the reacted material;

[0037] c. Post-treatment: Grinding (or chopping) the reacted material, washing it with water for 2 to 5 times (to purify it), and then drying it at a temperature of 20 to 100°C (to a constant weight) to obtain a polymer material product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com