Poly (tetramethylguandium acrylate) aqueous solution desulfurization agent and preparation method thereof

A technology of tetramethylguanidine polyacrylate and aqueous solution, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve the inevitable problems of low utilization rate of absorbent, low utilization rate of absorbent, high economic pressure, etc. , to achieve the effects of low production cost, reduced impact, and fast desulfurization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

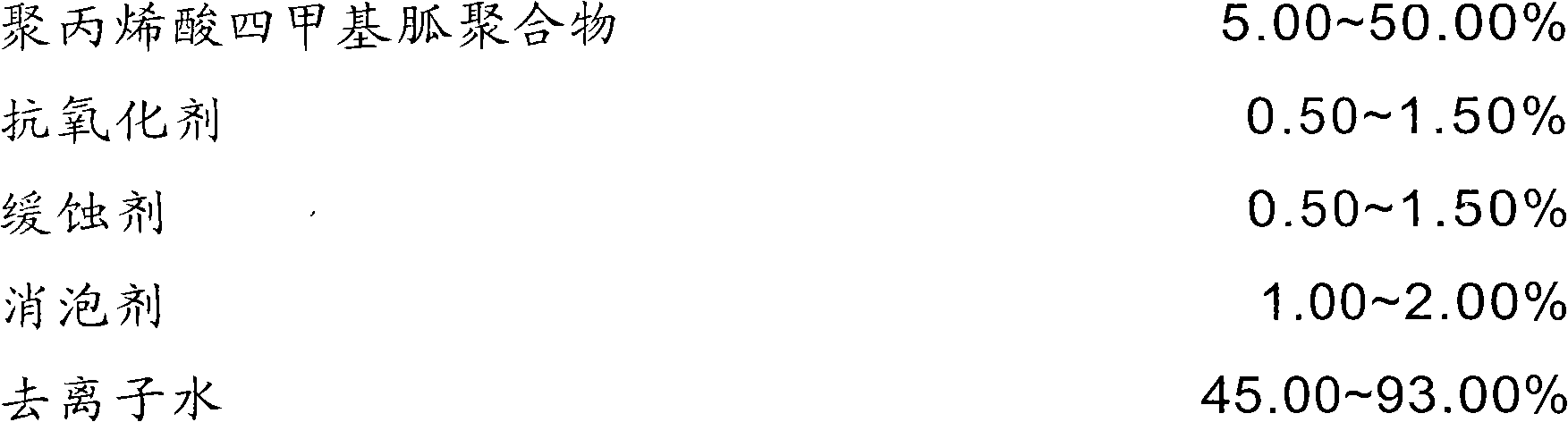

Method used

Image

Examples

Embodiment 1

[0020] 1) Put 100ml of solvent and 1.00g initiator into a 250ml three-necked flask, start stirring, slowly raise the temperature to 120°C, weigh 20.00g of acrylic acid, slowly add dropwise to the three-necked flask with a separatory funnel, continue to stir and react for 120min , The solvent was removed under reduced pressure to obtain a white solid called polyacrylic acid, which was crushed.

[0021] 2) Put 18.00g polyacrylic acid and 100ml deionized water into a 250ml three-necked bottle at 0~5℃, stir to dissolve, slowly add 28.75g tetramethylguanidine dropwise, and stir for 60~90min to obtain polyacrylic acid four Methylguanidine polymer aqueous solution.

[0022] 3) Add 1.00g hydroquinone antioxidant, 0.50g basic copper carbonate, and 1.00g silicone defoamer to the polyacrylic acid tetramethylguanidine polymer aqueous solution at room temperature to obtain polyacrylic acid tetramethylguanidine polymer Aqueous desulfurizer.

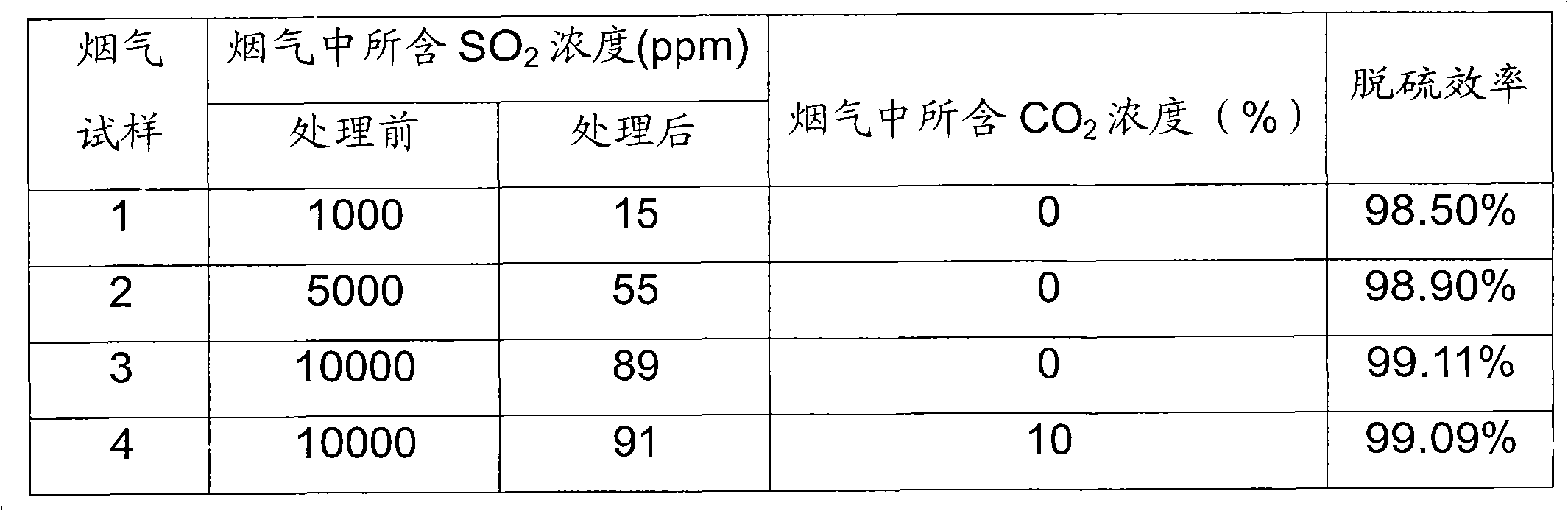

[0023] Based on the polyacrylic acid tetramethylguani...

Embodiment 2

[0028] 1) Put 100ml of solvent and 2.00g initiator into a 250ml three-necked flask, start stirring, slowly raise the temperature to 120℃, weigh 20.00g acrylic acid, slowly add dropwise to the three-necked flask with a separatory funnel, continue to stir and react for 120min , The solvent was removed under reduced pressure to obtain a white solid called polyacrylic acid, which was crushed.

[0029] 2) Put 18.00g polyacrylic acid and 100ml deionized water into a 250ml three-necked bottle at 0~5℃, stir to dissolve, slowly add 28.75g tetramethylguanidine dropwise, and stir for 60~90min to obtain polyacrylic acid four Methylguanidine polymer aqueous solution.

[0030] 3) Add 1.00g hydroquinone antioxidant, 0.50g basic copper carbonate, and 1.00g silicone defoamer to the polyacrylic acid tetramethylguanidine polymer aqueous solution at room temperature to obtain polyacrylic acid tetramethylguanidine polymer Aqueous desulfurizer.

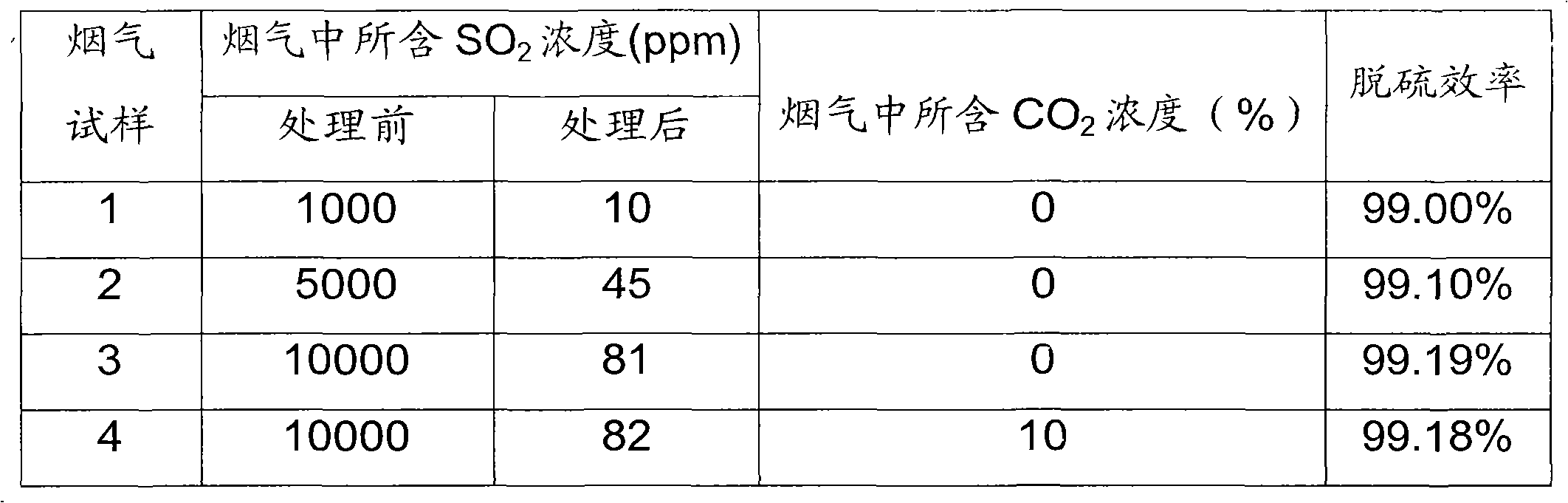

[0031] Based on the polyacrylic acid tetramethylguanidine...

Embodiment 3

[0036] 1) Put 100ml of solvent and 3.00g initiator into a 250ml three-necked flask, start stirring, slowly raise the temperature to 120℃, weigh 20.00g acrylic acid, slowly add dropwise to the three-necked flask with a separatory funnel, continue to stir and react for 120min , The solvent was removed under reduced pressure to obtain a white solid called polyacrylic acid, which was crushed.

[0037] 2) At 0~5℃, put 18.00g polyacrylic acid and 100ml deionized water into a 250ml three-necked bottle, stir to dissolve, slowly add 28.75g tetramethylguanidine dropwise, and stir for 60~90min to obtain polyacrylic acid tetra Methylguanidine polymer aqueous solution.

[0038] 3) Add 1.00g hydroquinone antioxidant, 0.50g basic copper carbonate, and 1.00g silicone defoamer to polyacrylic acid tetramethylguanidine polymer aqueous solution at room temperature to obtain polyacrylic acid tetramethylguanidine polymer Aqueous desulfurizer.

[0039] Based on the polyacrylic acid tetramethylguanidine p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com