Preparation method of nanometer strontium titanate catalyst

A nanometer strontium titanate and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, titanium compounds and other directions, can solve the problems of complex preparation process steps, corrosion of experimental equipment, experimental environment pollution, etc., and achieves simple process steps. , the effect of less equipment and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

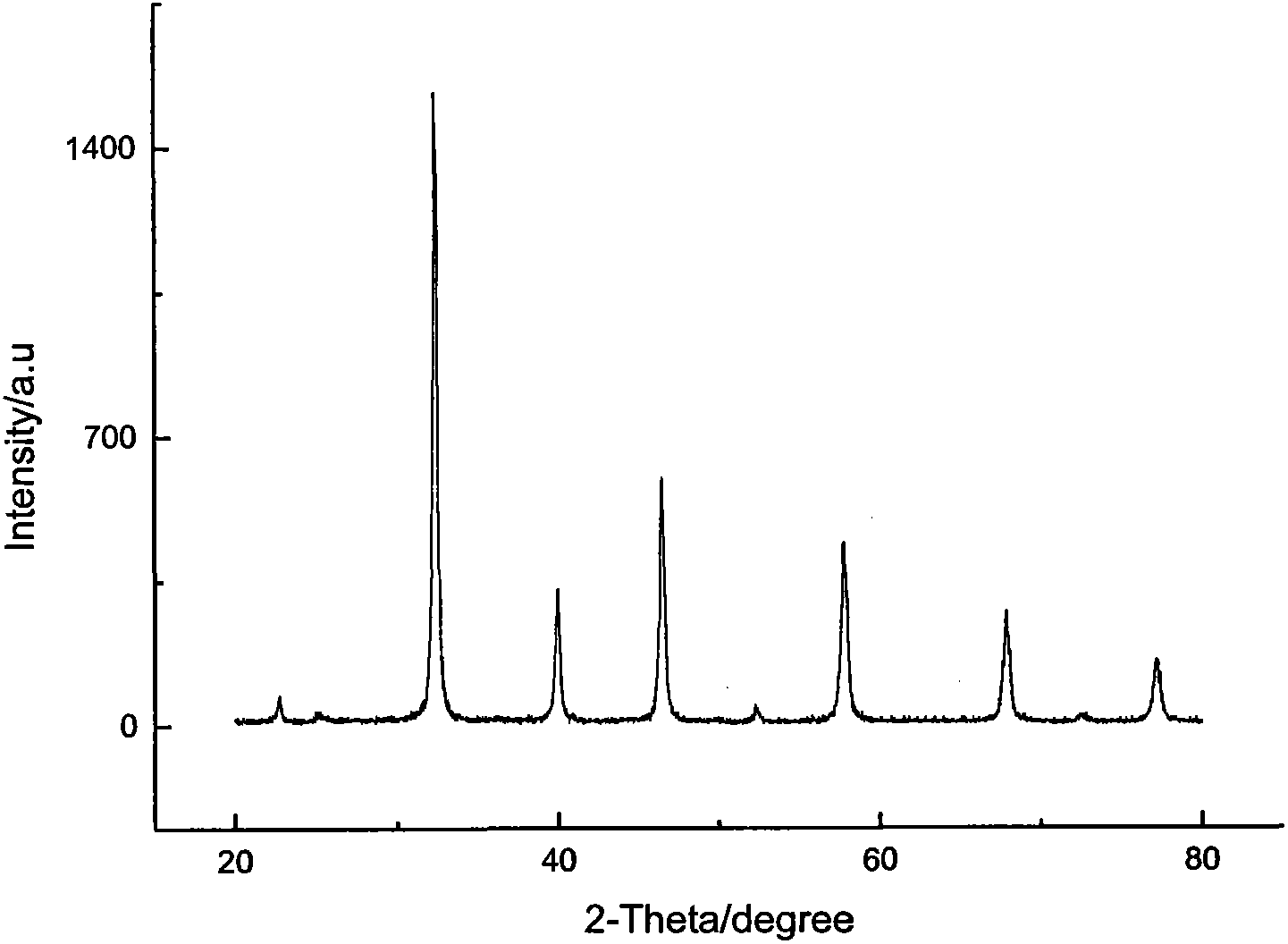

Image

Examples

Embodiment 1

[0021] A kind of preparation method of nano strontium titanate catalyst, its concrete steps are as follows:

[0022] (1) prepare the tartaric acid solution of strontium carbonate

[0023] Taking strontium carbonate as raw material, using tartaric acid aqueous solution as solvent, according to the ratio of the amount of substance (mol) of strontium carbonate: the amount of substance of tartaric acid (mol): the volume (mL) of deionized water is the ratio of 1: 2: 100 , adding strontium carbonate and tartaric acid into a reaction vessel filled with deionized water, stirring at a constant temperature of 60° C. for 10 min to prepare a transparent mixed solution of strontium carbonate and tartaric acid.

[0024] (2) Preparation of homogeneous sol

[0025] After step (1) is completed, use butyl titanate as raw material, and add butyl titanate to the mixed solution of strontium carbonate and tartaric acid prepared in step (1) under the condition that the stirring speed is 300r / min T...

Embodiment 2

[0029] A kind of preparation method of nano-strontium titanate catalyst, with embodiment 1, wherein:

[0030] In the 1st (1) step, the amount of substance (mol) of strontium carbonate: the amount of substance (mol) of tartaric acid: the volume (mL) of deionized water is 1: 1: 50, and stirring temperature is 40 ℃, and stirring time is 5min.

[0031] , in step (2), the stirring speed is 200r / min, the stirring temperature is 70°C, and the stirring time is 10min.

[0032] In the step (3), the oven drying temperature is 80° C., the drying time is 8 hours, the muffle furnace firing temperature is 700° C., and the firing time is 1.5 hours.

Embodiment 3

[0034] A kind of preparation method of nano-strontium titanate catalyst, with embodiment 1, wherein:

[0035] In the (1) step, the amount of substance (mol) of strontium carbonate: the amount of substance (mol) of tartaric acid: the volume (mL) of deionized water is 1: 3: 150, and stirring temperature is 80 ℃, and stirring time is 15min.

[0036] In step (2), the stirring speed is 400 r / min, the stirring temperature is 90° C., and the stirring time is 30 min.

[0037] In step (3), the oven drying temperature is 100° C., the drying time is 12 hours, the muffle furnace firing temperature is 900° C., and the firing time is 2.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com