Trichlorosilane synthesis gas dust removal method

A technology of trichlorosilane and synthesis gas, applied in separation methods, silicon halide compounds, chemical instruments and methods, etc., can solve pipeline and/equipment blockage, affect the continuous and safe operation of trichlorosilane synthesis gas dust removal system, etc. problems, to achieve the effect of clean and smooth filter screen, prolong the continuous running time, and solve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The dedusting method of the trichlorosilane synthesis gas is to react the silicon powder and hydrogen chloride gas in a fluidized bed reactor to obtain the trichlorosilane synthesis gas after rough dust removal and wet spraying treatment, and then carry out the following steps to: which handles:

[0028] (1), mix the waste slag obtained in the coarse dedusting step and the slurry obtained in the wet spraying step (the solid content of the slurry is 17%w, and "%w" in the present invention represents the weight percentage) to obtain a mixed slurry , the solid content of the mixed slurry is 41%w;

[0029] (2) Separating chlorosilanes from the mixed slurry to obtain a filter cake (the solid content of the filter cake is 79.8%w) and chlorosilanes;

[0030] (3), hydrolyzing the filter cake.

[0031] The trichlorosilane synthesis gas is processed through the dust removal method of the trichlorosilane synthesis gas in this example, and the production is continuous and safe, a...

Embodiment 2

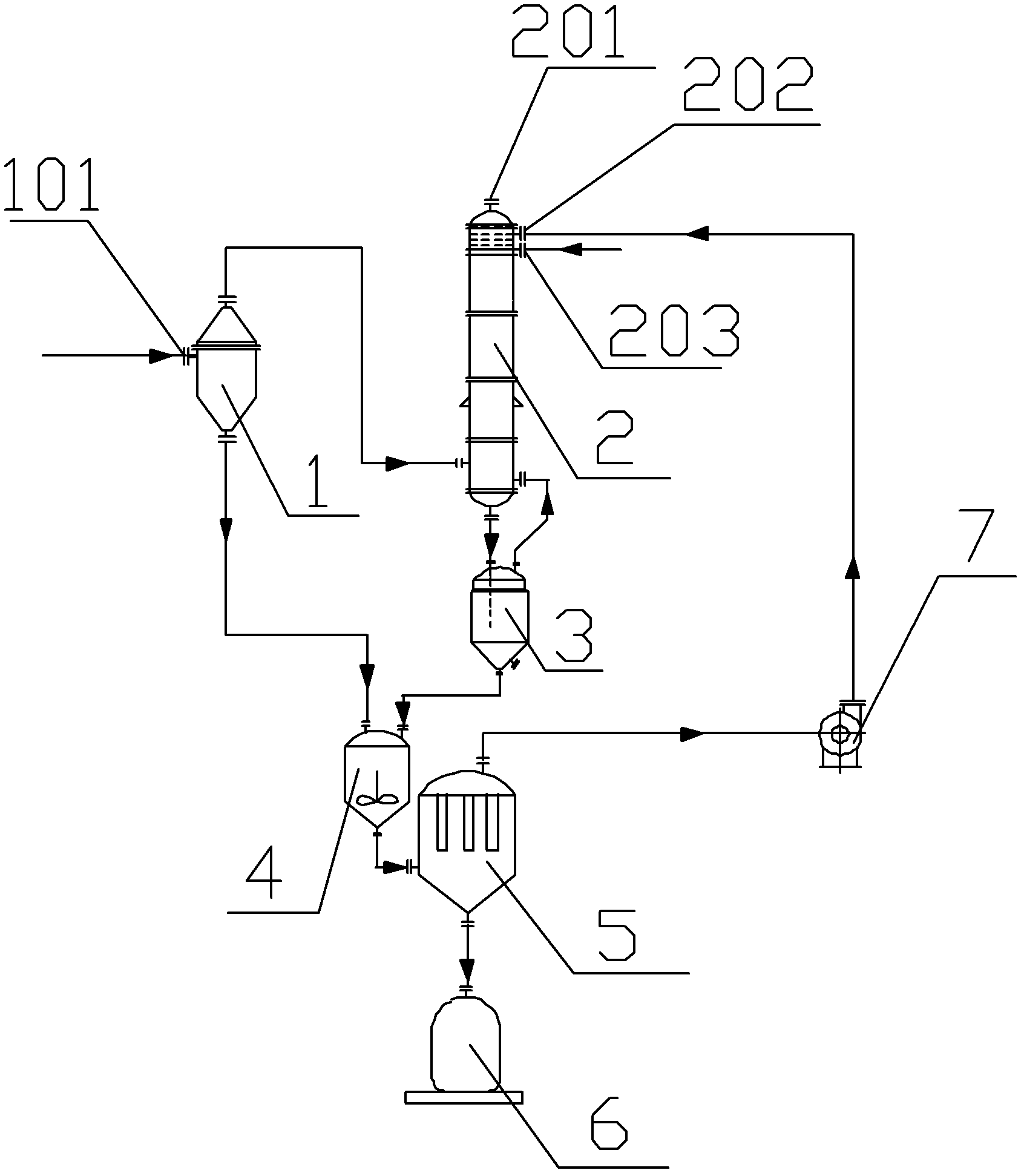

[0033] see figure 1 , the dedusting method of trichlorosilane synthesis gas, it comprises the steps:

[0034] (1), coarse dedusting: the trichlorosilane synthesis gas is passed through the first gas-solid separator inlet 101 into the first gas-solid separator 1 for coarse dedusting, and most of the solid particles in the synthesis gas are separated;

[0035] (2), wet spraying: pass the gas after coarse dedusting into the spray tower 2, use the chlorosilane liquid that enters the spray tower 2 through the second input port 203 of the spray liquid to cool down the synthesis gas, Rinse to remove high-boiling impurities in the synthesis gas and solid powders that cannot be completely removed in the gas-solid separator, and the dedusted trichlorosilane synthesis gas is discharged from the gas outlet 201 of the spray tower 2;

[0036] (3), mixed waste residue and slurry: collect the waste residue obtained in the rough dedusting step and the slurry obtained in the wet spraying step ...

Embodiment 3

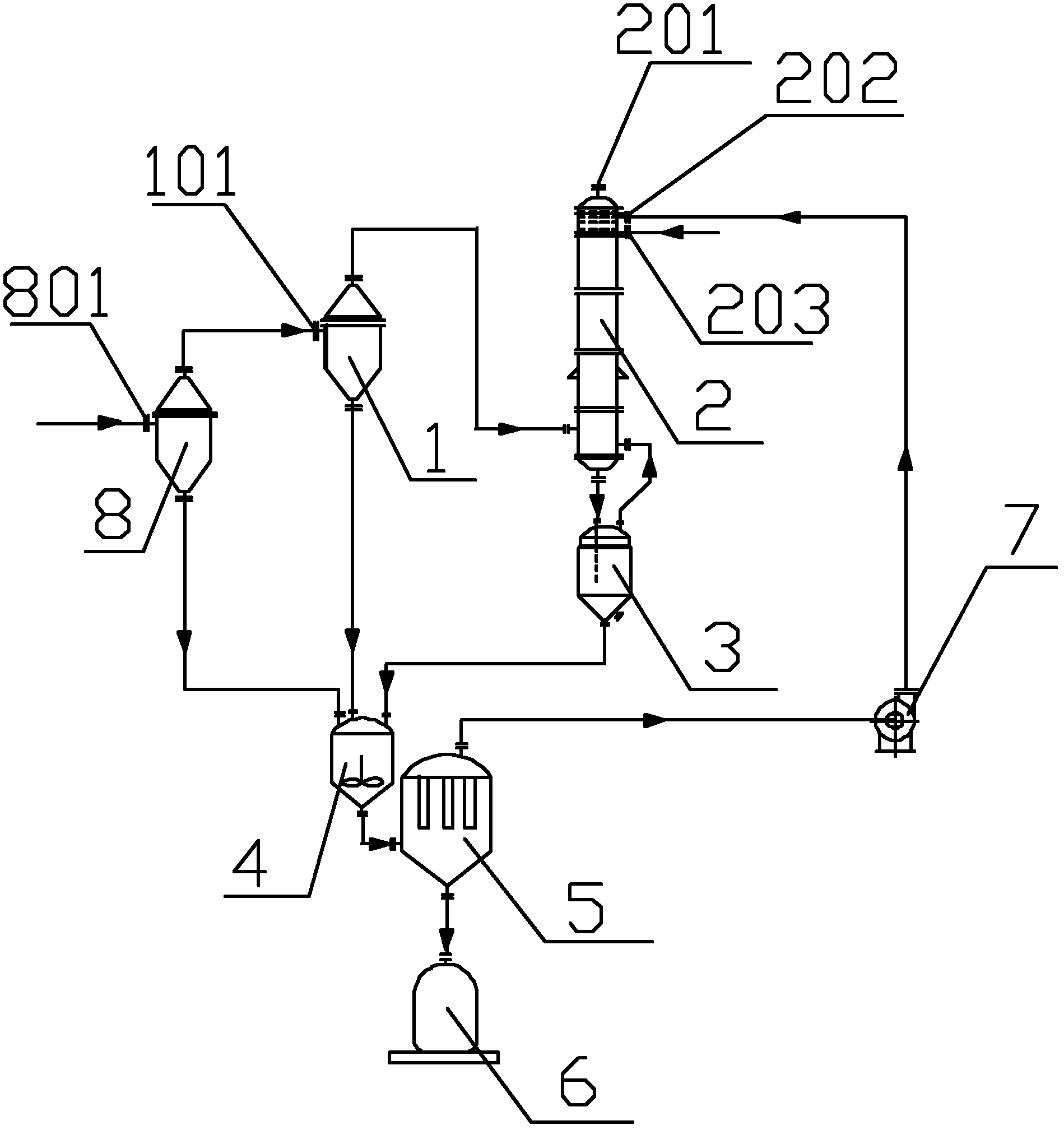

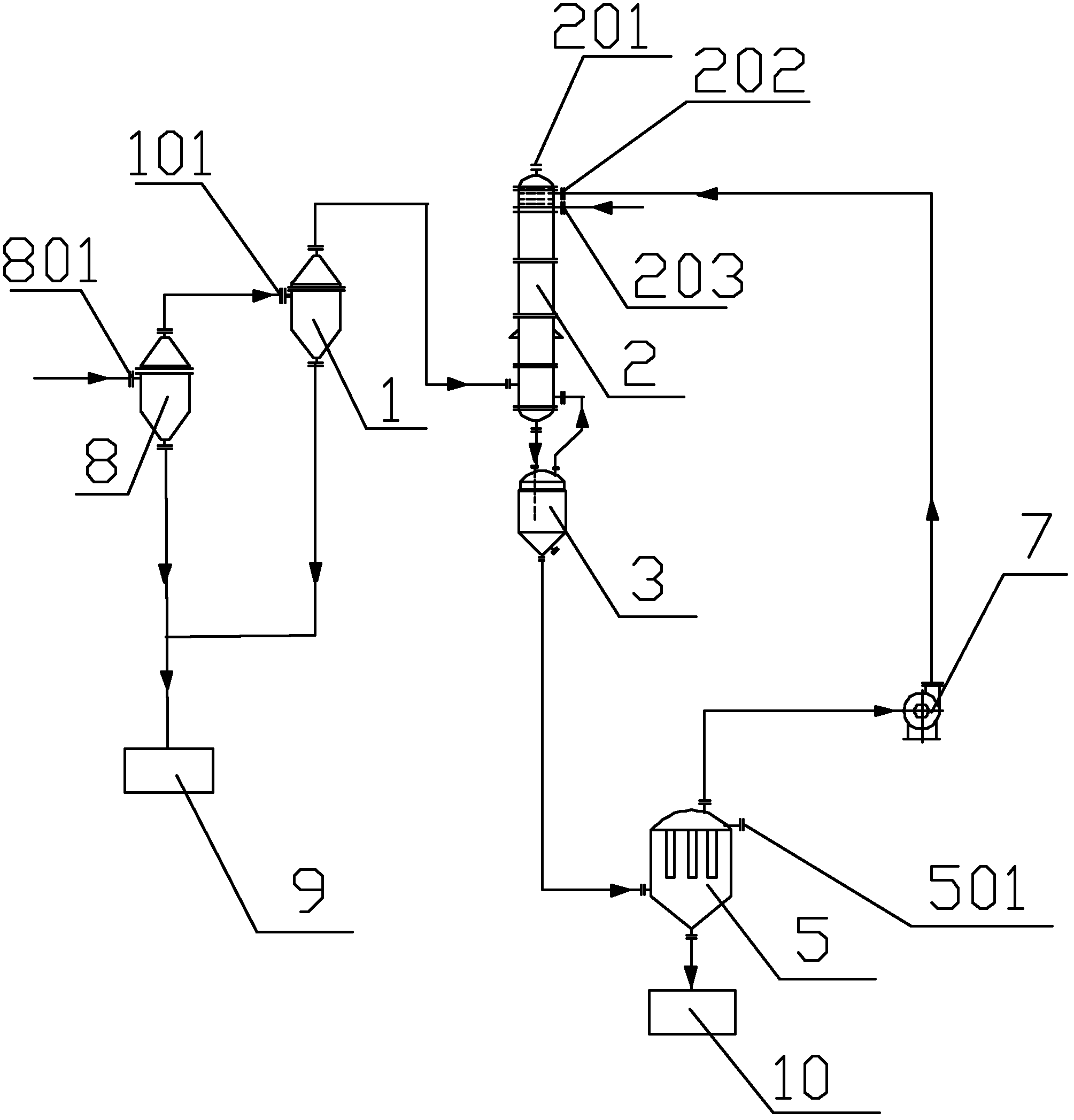

[0042] see figure 2 , the dedusting method of trichlorosilane synthesis gas, it comprises the steps:

[0043] (1), coarse dedusting: pass the trichlorosilane synthesis gas into the second gas-solid separator 8 through the second gas-solid separator inlet 801, pass through the second gas-solid separator 8 and the first gas-solid separator 1 Coarse dedusting, separating most of the solid particles in the synthesis gas, the working temperature of the first gas-solid separator 1 and the second gas-solid separator 8 is 180°C, and the working pressure is 0.2MPa;

[0044] (2), wet spraying: pass the gas after coarse dedusting into the spray tower 2, use the chlorosilane liquid that enters the spray tower 2 through the second input port 203 of the spray liquid to cool down the synthesis gas, Washing, the washed liquid is then evaporated by the evaporator 3, and the gas phase components enter the spray tower 2 and are washed by the chlorosilane liquid again to remove the high-boiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com