Functional high molecular sensing material with potassium ion selectivity based on click chemistry and application thereof

A technology of click chemistry and sensing materials, applied in the field of functionalized polymer sensing materials and their preparation, can solve the problems of limited methods and decomposition of sensing active components, and achieve simple steps, prolonged service life and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

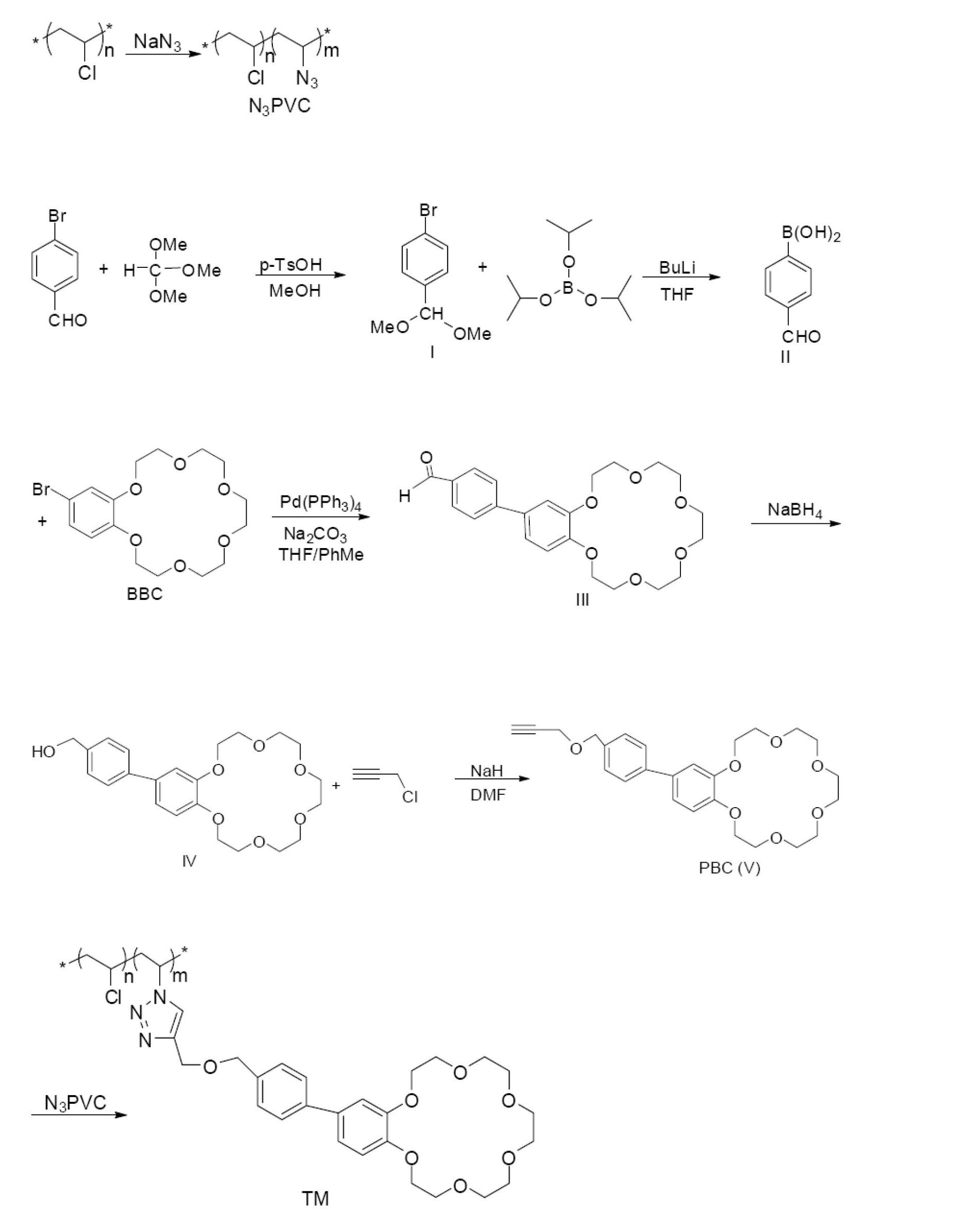

[0049] Example 1: Synthesis of novel functionalized polymer sensing material TM.

[0050] The synthesis of the new functional polymer sensing material TM can be divided into two parts: the activation of polyvinyl chloride and the synthesis and immobilization of the carrier (see figure 1 ).

[0051] The specific steps are:

[0052] (1) Activation of PVC:

[0053] In a 100mL four-necked bottle, add 1g PVC (16mmol, 1.0eq), 1.04g NaN 3 (16mmol, 1.0eq), 42mL DMF and H 2 Mixed solution of O (volume ratio 5:1), N 2 protection, magnetic stirring, oil bath heating, and the temperature is kept at 70-80°C. After reacting for 12 hours, stop the reaction, cool to room temperature, filter, wash the filter cake with distilled water and methanol, and dry under reduced pressure to obtain a white solid.

[0054] (2) Synthesis and immobilization of the carrier:

[0055] Step (2a): Add 20g p-bromobenzaldehyde (0.11mol), 0.04g p-toluenesulfonic acid (0.23mmol), 24mL trimethyl orthoformate (...

Embodiment 2

[0063] Same as the method of Example 1, the difference is that in step (1), the mol ratio of polyvinyl chloride and sodium azide is 1:3, in the mixed solvent of tetrahydrofuran and water by volume ratio 8:1, Under the protection of a rare gas atmosphere and at 80° C., the reaction was stirred for 48 hours.

Embodiment 3

[0065] The same method as in Example 1, except that in step (2a), the organic solvent is ethanol or tetrahydrofuran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com