Production of chiral alpha-hydroxy acid and its strain by using biological catalysis method

A technology for strains and hydroxy acids, applied in the field of biocatalytic production of chiral alpha-hydroxy acids and strains thereof, can solve the problems of low atom economy, low conversion rate and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

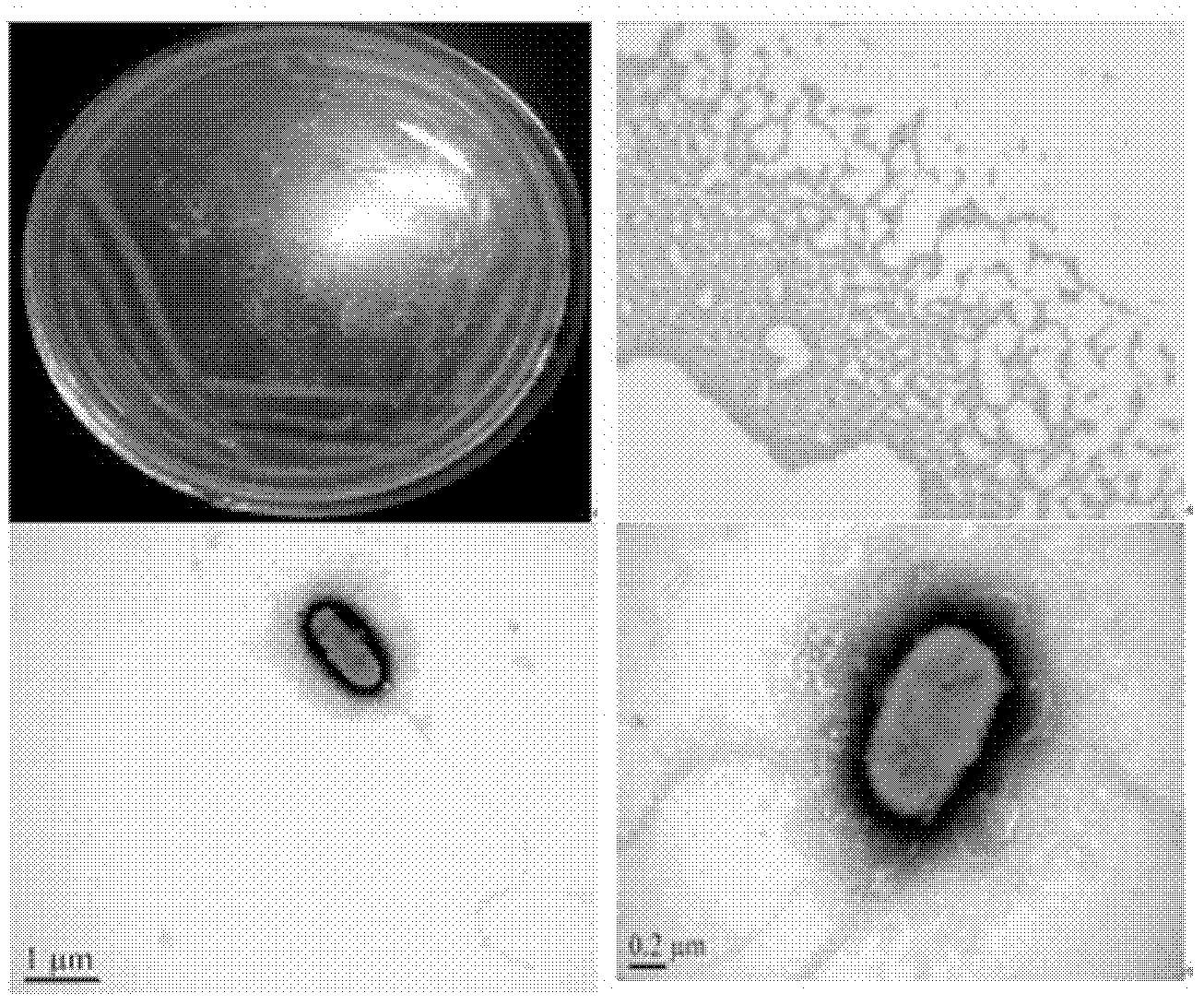

[0069] Example 1: Screening of strains capable of resolving racemic alpha-hydroxy acids to produce single enantiomers

[0070] Collect soil samples around chemical plants all over the country, take 1g of soil samples and dissolve them in 10ml of 0.9% normal saline, break the glass beads and let stand for 10 minutes, pipette 1-2ml of the suspension to contain 50mL of enrichment medium (Preparation: Mandelic acid 10g, (NH 4 ) 2 SO 4 10g, KH 2 PO 4 2.5g, K 2 HPO 4 2.5g, MgSO 4 .7H 2 O 0.2g, FeSO 4 .7H 2 0 0.03g, 1g of NaCl, make up to 1L with water, adjust the pH to 7.0) in a 250mL Erlenmeyer flask, culture on a shaker for 2 to 3 days (30°C, 150r / min) until the culture medium is turbid, and the turbid enrichment culture The inoculum was transferred to fresh enriched culture medium with 2% inoculum for culture, repeated 2 to 3 times, the concentration of racemic mandelic acid could be increased correspondingly to increase the selection pressure, and then the culture m...

Embodiment 2

[0073] Embodiment 2: the fermentation culture of Pseudomonas aeruginosa CCTCC NO: M 2011394

[0074] Fermentation medium: mannitol 10g / L, yeast extract powder 10g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, CuCl 2 0.01g / L, NaCl 1g / L, inducer o-chloromandelic acid 2.5g / L, prepared in tap water, pH 7.0, sterilized at 121°C for 20min. After sterilization, cool down and inoculate. Fill a 250mL Erlenmeyer flask with 20% liquid, inoculate a ring of Pseudomonas aeruginosa CCTCC NO: M 2011394, culture at 30°C and 150rpm for 48 hours, centrifuge the fermentation broth and wash it twice with normal saline, and collect the wet bacteria after centrifugation somatic cells. The maximum specific growth rate μ of Pseudomonas aeruginosa CCTCCNO: M 2011394 was found through experimental research m =0.2322h -1 , the biomass doubling time is t d = 2.98h.

Embodiment 3

[0075] Embodiment 3: the fermentation culture of Pseudomonas aeruginosa CCTCC NO: M 2011394

[0076] Medium: mannitol 10g / L, yeast extract powder 10g / L, K 2 HPO 4 2.5g / L, KH 2 PO 4 2.5g / L, CuCl 2 0.01g / L, NaCl 1g / L, inducer o-chloromandelic acid 2.5g / L, prepared in tap water, pH 7.0, sterilized at 121°C for 20min. Cool after sterilization. Fill a 250mL Erlenmeyer shaker flask with 20% liquid, inoculate a ring of Pseudomonas aeruginosa CCTCC NO: M 2011394, culture at 30°C and 150rpm for 24 hours as seed liquid, and receive sterilized fresh medium with 2% inoculum As a fermentation broth, culture at 30°C and 150rpm for 48 hours with shaking. After the end, the fermentation broth was centrifuged and washed twice with saline. After centrifugation, the wet bacterial cells were collected, and the dry weight of the bacterial cells reached 4.2g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com