Method for producing high-enzyme-activity pectate lyase by means of raw material pretreatment and feed fermentation

A fed-batch fermentation and pretreatment technology, which is applied in the field of production of alkaline pectinase with high enzyme activity, can solve the problems of low activity of alkaline pectinase, unsuitability for industrial production, and high cost, so as to shorten the fermentation cycle and improve flow rate. Sexuality and oxygen carrying capacity, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Bacillus subtilis CCTCC NO:M200038 (applicant deposited in China Center for Typical Cultures (CCTCC) on November 20, 2000, see ZL01106844.2 for related patents) was activated on an inclined plane, and the bacterial lawn was inoculated to the medium containing the seeds The shake flasks were cultured under the following conditions: 300ml Erlenmeyer flask with 50ml liquid volume, fermentation temperature 37°C, 200rpm shaking culture for 8h. Inoculate the initial fermentation medium with an inoculum size of 10%, at a temperature of 33-34°C, and an aeration volume of 2.5-4.5L min -1 . The starch in the feed medium was liquefied with mesophilic amylase, and the amount of enzyme added was 25U g -1 , the liquefaction temperature is 60°C, and the liquefaction time is 35min. After the initial fermentation to 14 hours, add the feed medium after pretreatment according to 20% of the volume of the initial fermentation medium, control the temperature at 33-34°C, and the ventilation...

Embodiment 2

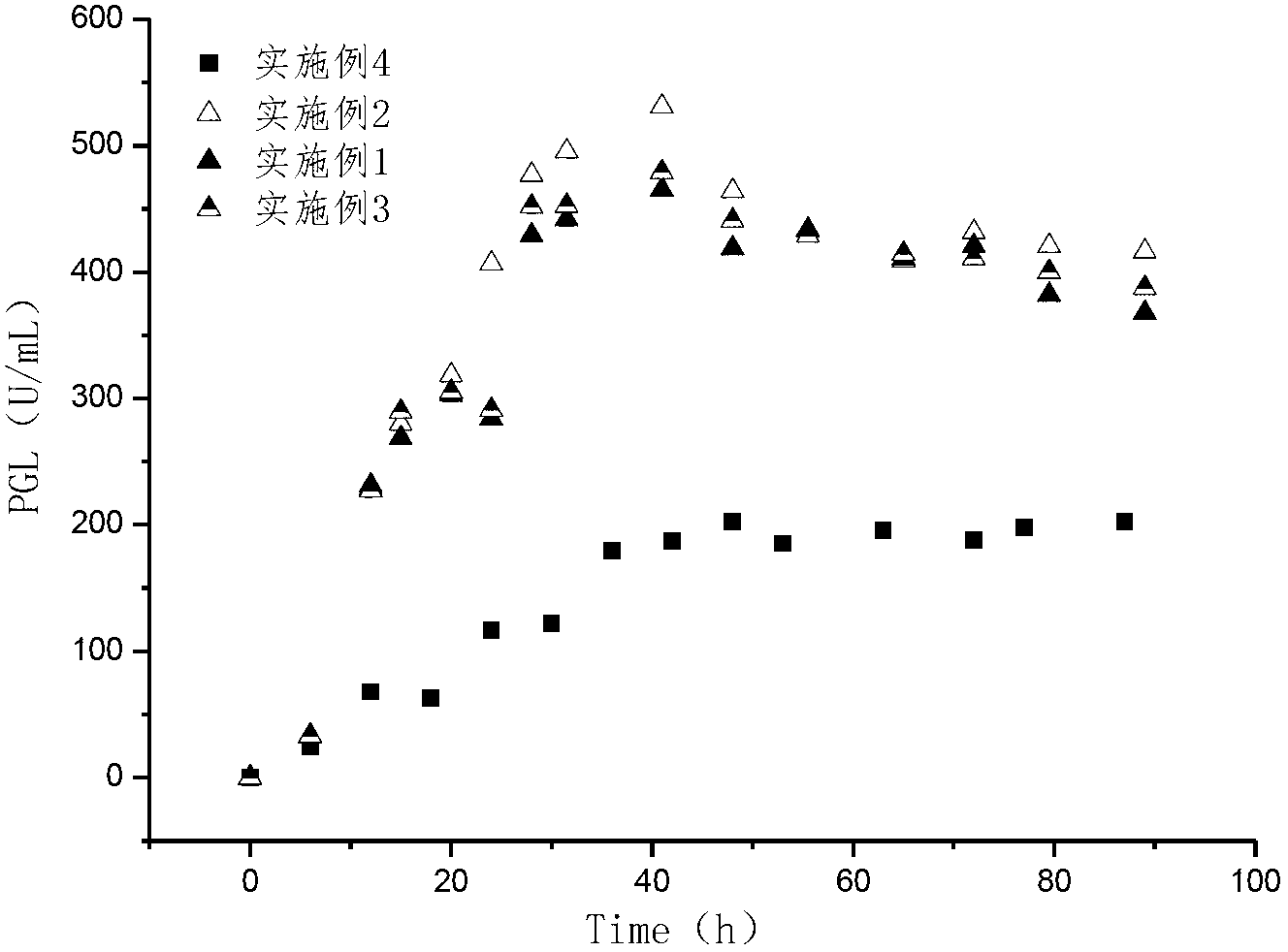

[0035] Fermentation method, condition are all the same as embodiment 1 except following changes. In the pretreatment process, the amount of enzyme added by mesophilic amylase is 32.5U g -1 , the liquefaction temperature is 55°C, and the liquefaction time is 30min. Primary fermentation to 16h feeding. The fermentation period is 36-48h, and the highest alkaline pectinase activity of the obtained crude enzyme solution is 531U mL -1 . Fermentation see figure 1 . Wherein the culture medium formula is as follows:

[0036] The composition of the seed medium is: glucose 11g L -1 , yeast powder 4,5g L -1 , peptone 4.5g L -1 , NaCl 4.5g L -1 , K 2 HPO 4 10gL -1 , pH 8.0;

[0037] The composition of the fermentation medium is: starch 20g L -1 , wheat bran 40g L -1 , (NH 4 ) 2 SO 4 1.5gL -1 , MgSO 4 ·7H 2 O 1gL -1 ;

[0038] The feed medium composition is: starch 122.5g L -1 , wheat bran 10.5g L -1 , (NH 4 ) 2 SO 4 10gL -1 , MgSO 4 ·7H 2 O6.5gL -1 .

Embodiment 3

[0040] Fermentation method, condition are all the same as embodiment 1 except following changes. In the pretreatment process, the amount of amylase added in the middle temperature is 40U g -1 , the liquefaction temperature is 50°C, and the liquefaction time is 25min. Primary fermentation to 18h feeding. The fermentation period is 36-48h, and the final alkaline pectinase activity of the obtained crude enzyme solution is 479UmL -1 . Fermentation see figure 1 . Wherein the culture medium formula is as follows:

[0041] The composition of the seed medium is: glucose 13g L -1 , yeast powder 6g L -1 , peptone 6g L -1 , NaCl 6g L -1 , K 2 HPO 4 12gL -1 , pH 8.0;

[0042] Above-mentioned fermentation medium composition is: starch 25g L -1 , wheat bran 45g L -1 , (NH 4 ) 2 SO 4 2g L -1 , MgSO 4 ·7H 2 O 1.5g L -1 ;

[0043] The composition of the above-mentioned feeding medium is: starch 130g L -1 , wheat bran 13g L -1 , (NH 4 ) 2 SO 4 14g L -1 , MgSO 4 ·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com