Antioxidant peptide and preparation method thereof

An antioxidant peptide, separation and purification technology, applied in the field of food biology, can solve the problems of peanut protein denaturation, color and smell deterioration, etc., and achieve the effect of small molecular weight, strong activity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of koji enzyme: Mix 20g of bran, 10g of peanut meal, 0.05g of calcium chloride and 30g of deionized water; sterilize in a high-pressure steam sterilizer at 100°C for 30min, cool to 38°C, and inoculate Aspergillus oryzae, cultivated in an incubator at 30°C for 48h; add 200mL of deionized water, stir in a 30°C water bath for 1h, at 0°C at 8000 × g Centrifuge for 20min, take the supernatant, and freeze-dry to obtain Aspergillus;

[0030](2) Preparation of peanut meal enzymatic hydrolyzate: mix peanut meal and water at a mass ratio of 1:7, add 0.5% koji-forming enzyme based on the protein mass of peanut meal, enzymatically hydrolyze at 55°C for 8 hours; Enzyme for 15 minutes, centrifuge, take the supernatant to obtain the peanut meal enzymatic solution, the degree of hydrolysis is 34.6%;

[0031] (3) Separation and purification of antioxidant peptides: pass the peanut meal enzymatic solution through an ultrafiltration membrane with a molecular weight cut-of...

Embodiment 2

[0034] (1) Preparation of koji enzyme: Mix 24g of bran, 15g of peanut meal, 0.06g of calcium chloride and 35g of deionized water; sterilize in a high-pressure steam sterilizer at 100°C for 30min, cool to 38°C, and inoculate Aspergillus oryzae, cultivated in an incubator at 28°C for 72h; add 200mL of deionized water, stir in a water bath at 50°C for 3h, at 2°C at 8000 × g Centrifuge for 20min, take the supernatant, and freeze-dry to obtain Aspergillus;

[0035] (2) Preparation of peanut meal enzymatic hydrolyzate: mix peanut meal and water at a mass ratio of 1:7, add 1% koji-forming enzyme based on peanut meal protein, enzymatically hydrolyze at 55°C for 12h; sterilize at 95°C Enzyme for 30 minutes, centrifuge, take the supernatant to obtain the peanut meal enzymatic hydrolysis solution, the degree of hydrolysis is 36.3%;

[0036] (3) Separation and purification of antioxidant peptides: pass the peanut meal enzymatic solution through an ultrafiltration membrane with a molecula...

Embodiment 3

[0039] Carry out in the same manner as in Embodiment 2, except that the enzymatic hydrolysis is carried out at 55° C. for 24 hours to obtain an enzymatic hydrolyzate of peanut meal, and the degree of hydrolysis is increased to 39.9%.

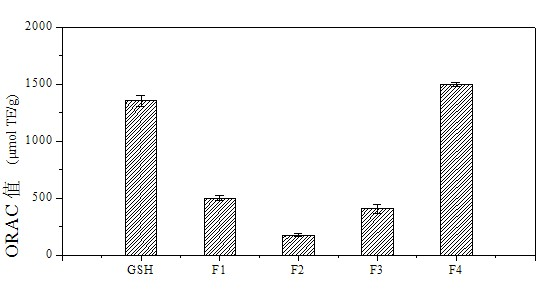

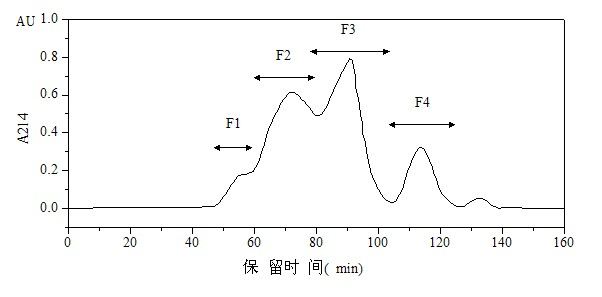

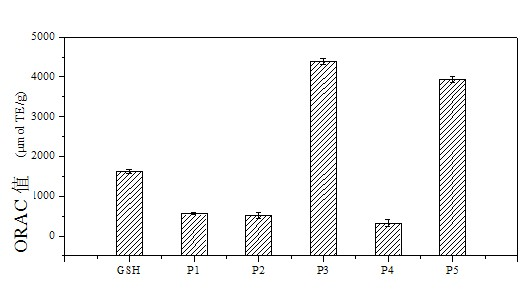

[0040] Fig. 1 is Sephadex G-15 gel filtration chromatographic separation and purification antioxidant peptide map, wherein Figure 1a For the determination of antioxidant activity, Figure 1b Elution curve for chromatographic separation. It can be seen from Figure 1 that the activity of component F4 is the highest. Figure 2 is a semi-preparative HPLC separation and purification antioxidant peptide map, in which Figure 2a For the determination of antioxidant activity, Figure 2b It is the elution curve of chromatographic separation, and it can be seen from Fig. 2 that component P3 has the highest activity. Fig. 3 is a mass spectrometry analysis diagram of the amino acid sequence Tyr-Gly-Ser of the antioxidant peptide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com