Composite metal nitrogen-doped carbon nanotube catalyst, preparation method thereof and method for catalyzing biodiesel by utilizing catalyst

A composite metal and carbon nanotube technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reducing production costs, high prices, disadvantages, etc., to reduce production costs, reduce The generation of waste water and the effect of shortening the flow of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Na-CN X preparation of

[0026] First put the Fe / SBA-15 catalyst into a ceramic boat, heat the quartz tube furnace to 800K, and then pass the Ar / organic amine mixed gas at a certain flow rate. Fe / SBA-15 catalyst to obtain pure CNx nanotubes, and then immerse them in an aqueous solution of sodium carbonate with a mass fraction of 50%, stir evenly, immerse for 24 hours, centrifuge, and dry in a constant temperature drying oven at 90°C for 24 hours , ground evenly, and then placed in a muffle furnace at 500°C for calcination for 5 hours to obtain Na-CN X nanotube catalyst.

[0027] (2) In the Na-CN X Preparation of biodiesel under the catalysis of nanotube catalyst

[0028] In a 250mL four-necked bottle equipped with a stirrer, a reflux condenser, a thermometer and a feeding device, add 0.5 kg of soybean oil, add 60% methanol of soybean oil quality into the reaction flask under vigorous stirring, and add 60% of soybean oil quality methanol 2% co-solvent n-hexane a...

Embodiment 2

[0030] (1) K-CN X preparation of

[0031]First put the Fe / SBA-15 catalyst into a porcelain boat, heat the quartz tube furnace to 1000K, and then pass the Ar / organic amine mixed gas at a certain flow rate. Fe / SBA-15 catalyst, to obtain pure CNx nanotubes, immerse CNx nanotubes in an aqueous solution of potassium carbonate with a mass fraction of 50%, stir evenly, immerse for 24 hours, centrifuge and dry in a constant temperature drying oven at 90°C for 24 Hours, ground evenly, and then placed in a muffle furnace at 500°C for calcination for 5 hours to obtain the K-CN of this example X nanotube catalyst.

[0032] 2) In the K-CN X Preparation of Biodiesel Catalyzed by Nanotube Catalysts

[0033] In a 250mL four-necked bottle equipped with an agitator, a reflux condenser, a thermometer and a feeding device, add 0.5Kg soybean oil, add methanol with 80% soybean oil quality into the reaction flask under vigorous stirring, and add 4% soybean oil quality % co-solvent n-hexane and ...

Embodiment 3

[0036] (1) Mg-CN X preparation of

[0037] First put the Fe / SBA-15 catalyst into a porcelain boat, heat it in a quartz tube furnace to 1100K, then pass in a mixed gas of Ar / organic amine at a certain flow rate, keep it at a constant temperature for 1.5 hours, and remove it with a dilute HF solution after natural cooling. Fe / SBA-15 catalyst, to obtain pure CNx nanotubes, immerse CNx nanotubes in an aqueous solution of magnesium nitrate with a mass fraction of 50%, stir evenly, impregnate for 24 hours, centrifuge, and dry in a constant temperature drying oven at 90 °C for 24 Hours, ground evenly, and then placed in a muffle furnace at 500°C for calcination for 5 hours to obtain Mg-CN X nanotube catalyst.

[0038] (2) In the Mg-CN X Preparation of Biodiesel Catalyzed by Nanotube Catalysts

[0039] In a 250mL four-necked bottle equipped with a stirrer, a reflux condenser, a thermometer and a feeding device, add 0.5Kg soybean oil, add methanol with 100% soybean oil quality into...

PUM

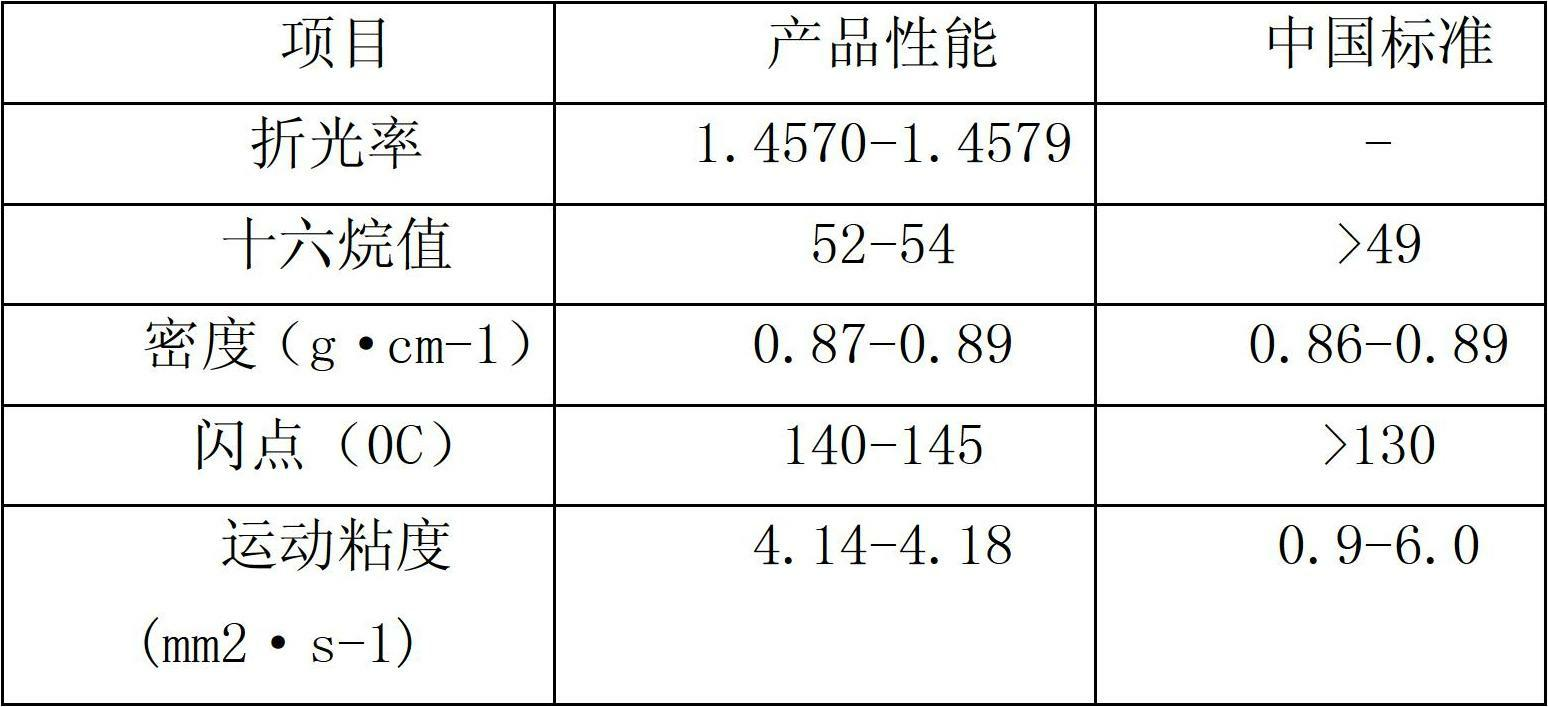

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com