Inorganic matrix anticorrosion material for metal oil tank

A technology of anti-corrosion materials and base metals, which is applied in the field of inorganic-based metal oil tank anti-corrosion materials and preparations, can solve the problems of high cost and short life, and achieve the effects of improved service life, long life and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

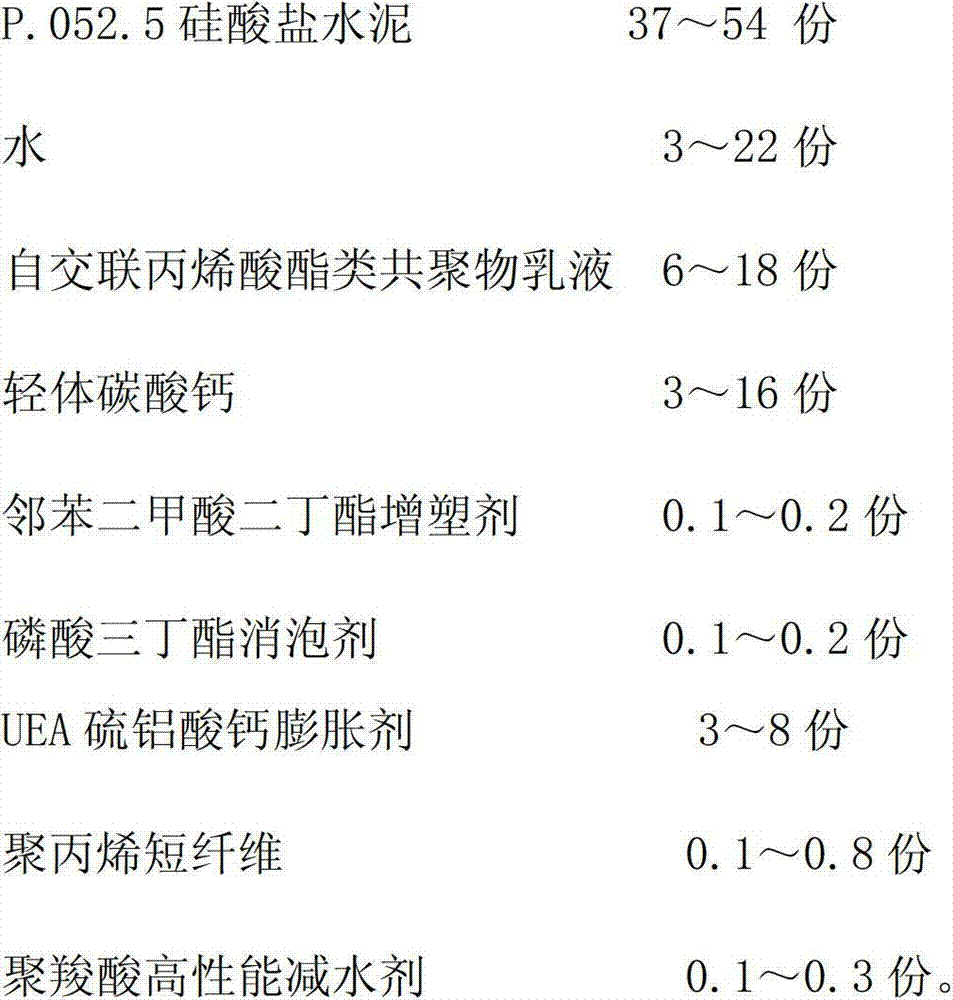

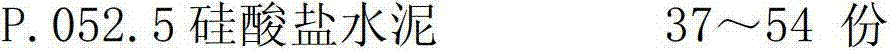

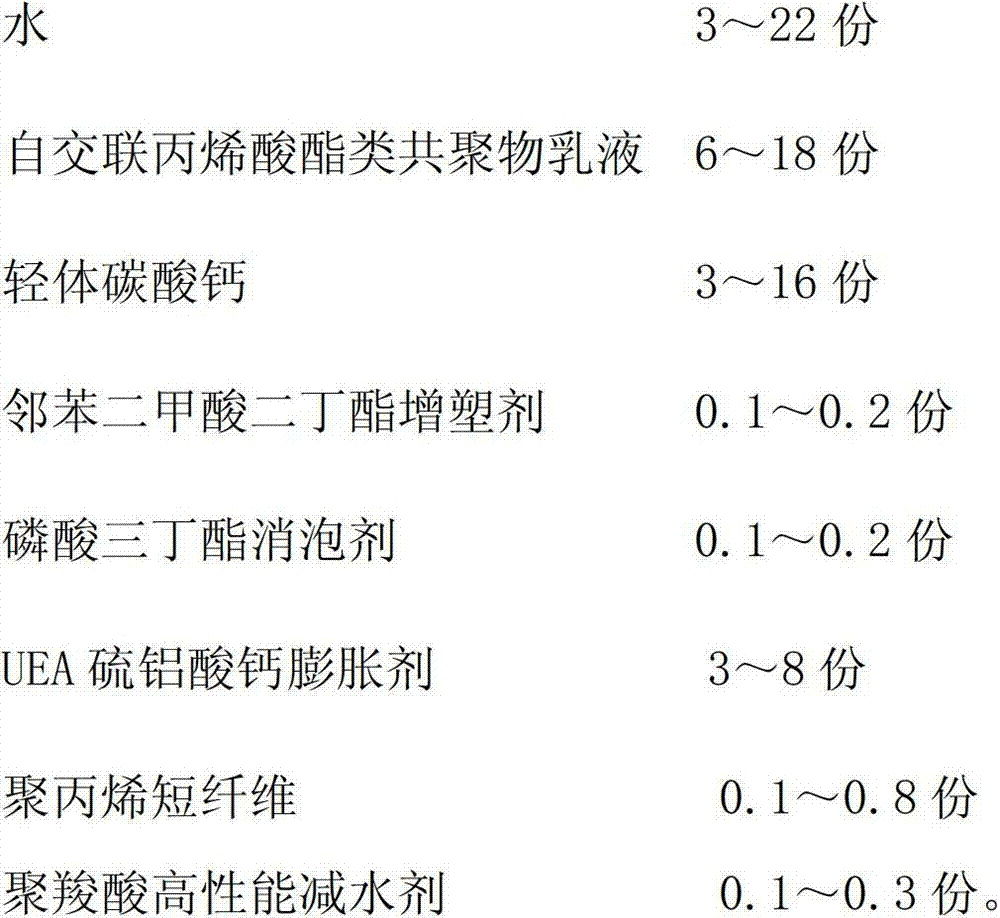

Method used

Image

Examples

Embodiment 1

[0014] Add P.052.5 Portland cement 37kg, water 3kg, self-crosslinking acrylate copolymer emulsion 18kg, light calcium carbonate 3kg, UEA calcium sulfoaluminate expansion agent 3kg and polypropylene short fiber 0.1kg in the mixing tank, Stir well (about 10 minutes); mix 100g of dibutyl phthalate plasticizer and 100g of polycarboxylate high-performance water reducer in advance, add slowly under stirring, and then add tributyl phosphate 100g of defoaming agent, fully stirred until there are no air bubbles (about 5 minutes or so), and the inorganic-based metal oil tank life-span anti-corrosion material slurry with protective performance in this embodiment is obtained.

[0015] During construction, the above slurry is stirred evenly, and the surface of the metal oil tank is sprayed with a high-pressure mortar spraying machine. The thickness of the anti-corrosion layer is about 2mm. After 5 days of curing, the inorganic-based composite anti-corrosion layer can be solidified on the su...

Embodiment 2

[0019] The process is the same as in Example 1, and the feeding amount is: 54kg of P.052.5 Portland cement, 22kg of water, 6kg of self-crosslinking acrylate copolymer emulsion, 16kg of light calcium carbonate, 8kg of UEA calcium sulfoaluminate expansion agent, polypropylene 0.8kg of short fibers, 300g of polycarboxylate high-performance water reducer, 200g of dibutyl phthalate plasticizer, and 200g of tributyl phosphate defoamer.

[0020] During construction, the above slurry is stirred evenly, and the surface of the metal oil tank is sprayed with a high-pressure mortar spraying machine. The thickness of the anti-corrosion layer is about 60mm. After 15 days of curing, the inorganic-based composite anti-corrosion layer can be solidified on the surface of the metal oil tank.

[0021] Main performance indicators:

[0022]

Embodiment 3

[0024] The process is the same as in Example 1, and the feeding amount is: 45kg of P.052.5 Portland cement, 42kg of water, 12kg of self-crosslinking acrylic copolymer emulsion, 9kg of light calcium carbonate, 5kg of UEA calcium sulfoaluminate expansion agent, polypropylene 0.4kg of short fibers, 200g of polycarboxylate high-performance water reducer, 150g of dibutyl phthalate plasticizer, and 150g of tributyl phosphate defoamer.

[0025] During construction, the above slurry is stirred evenly, and the surface of the metal oil tank is sprayed with a high-pressure mortar spraying machine. The thickness of the anti-corrosion layer is about 30mm. After 10 days of curing, the inorganic-based composite anti-corrosion layer can be solidified on the surface of the metal oil tank.

[0026] Main performance indicators:

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com